Explore Concrete Mix ratio, Grades of Concrete and their Comprehensive Strength (PSI)

Table of Contents

ToggleIntroduction:

Concrete, a fundamental construction building material, has played a pivotal role in construction for centuries. Composed of a mixture of cement, water, aggregates, and sometimes additives, concrete is renowned for its versatility, durability, and strength. This article explores the diverse world of concrete, from its composition to various types, applications, and strength ranges.

What are Concrete Grades?

Concrete grades are classifications that indicate the compressive strength of concrete at 28 days, as defined by the Bureau of Indian Standards (BIS). These grades are denoted by the prefix “M,” representing mix, followed by a number indicating the concrete’s strength in megapascals (MPa). The mix ratio of concrete components, such as cement, sand, and aggregates, contributes to its overall strength. Different grades cater to specific construction needs, with higher grades suitable for structures requiring superior strength, like dams and bridges

What Grades of Concrete:

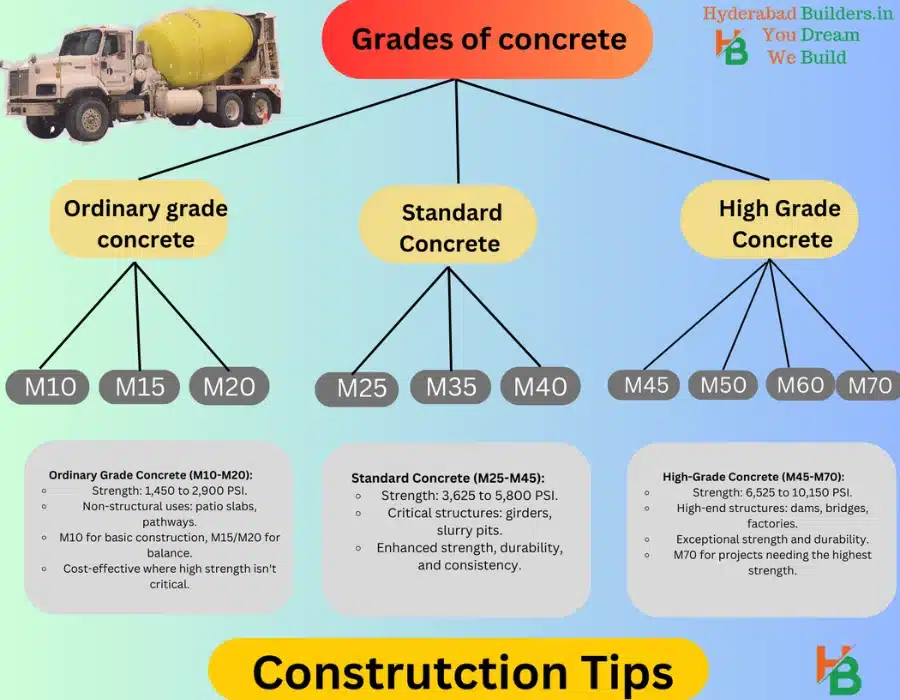

Concrete is graded into three types

1) Ordinary grade concrete

2) Standard Concrete

3) High Grade Concrete

Ordinary grade concrete

Ordinary Grade of Concrete includes M10, M15, and M20, characterized by a lower compressive strength ranging from 1,450 to 3,200 PSI. These grades are suitable for non-structural construction purposes, such as patio slabs, pathways, and residential flooring, where exceptionally high strength is not a primary requirement. They strike a balance between workability and strength, making them versatile for various applications in construction.

M10 (Compressive Strength: 1,450 PSI; Mix Ratio: 1:3:6 – Cement: Sand: Aggregates):

- Applications:

- Non-structural purposes where high strength is not a primary concern.

- Suitable for projects like patio slabs and pathways.

- Ideal for smaller construction projects where the load-bearing capacity is not a critical factor.

- Cost-effective choice for basic construction needs where structural integrity is not a priority.

M15 (Compressive Strength: 2,175 PSI):

- Applications:

- Well-suited for applications requiring a balance of strength and workability.

- Ideal for sealing floors due to its moderate strength.

- Construction of roads, where a good combination of strength and durability is necessary.

- Versatile for various projects that demand a moderate level of compressive strength without excessive requirements.

M20 (Compressive Strength: 2,900 PSI):

- Applications:

- Widely used in residential projects for various applications.

- Suitable for flooring, garages, and sheds in typical household constructions.

- Offers adequate strength to meet the demands of common residential needs.

- Provides a cost-effective solution for structures where high strength is not a critical factor.

Standard Concrete

Standard Grade of Concrete encompasses M25 to M45 grades, exhibiting enhanced compressive strength. These grades find application in constructing critical structures like concrete girders, slurry pits, high-tensile beams, and loading bays. With strengths ranging from 3,625 to 5,800 PSI, they offer durability and consistency, making them ideal for projects requiring robust internal and external support in construction.

Applications: Versatile grade for foundational structures providing internal support. Suitable for constructing various foundational elements in construction projects. Balances strength and workability, making it a versatile choice.

M30 (Compressive Strength: 4,350 PSI):

Applications: Highly durable and useful for roads facing harsh weather conditions and heavy vehicles. Suitable for areas with significant wear and tear, requiring a resilient concrete mix.

M35 (Compressive Strength: 5,075 PSI):

Applications: High consistency makes it suitable for constructing external walls of commercial buildings. Offers uniformity and strength for commercial construction projects.

M40 (Compressive Strength: 5,800 PSI):

Applications: Possesses high strength, suitable for holding heavy structures like beams. Anti-corrosive properties make it ideal for constructing septic tanks holding potent chemicals.

High Grade Concrete

High-Grade Concrete, spanning PSI strength from 6,525 to 9,425, comprises grades M45 to M65. Renowned for exceptional strength and durability, these grades are employed in constructing high-end structures like dams and bridges. With their robust composition, they ensure the integrity and longevity of critical constructions, meeting stringent requirements for heavyweight infrastructure projects.

M45 (Compressive Strength: 6,525 PSI):

Applications: Ideal for constructing substantial structures such as dams and factories.

Impressive strength ensures integrity in critical constructions.

M50 (Compressive Strength: 7,250 PSI):

Applications:

Designed mix for applications requiring a significant compressive strength.

Suitable for projects demanding high strength and durability.

M55 (Compressive Strength: 7,975 PSI):

Applications: Designed mix for construction projects needing superior strength.

Ideal for structures that face heavy loads and challenging conditions.

M60 (Compressive Strength: 8,700 PSI):

Applications: Designed mix with exceptional strength for specialized construction projects.

Suitable for structures where extreme strength and durability are paramount.

M65 (Compressive Strength: 9,425 PSI):

Applications: Designed mix for critical constructions like bridges and high-end buildings.

Impressive strength for structures facing intense stress and challenges.

M70 (Compressive Strength: 10,150 PSI):

Applications: M70 Designed mix for projects requiring the highest compressive strength.

Ideal for constructing structures where extreme strength is a critical factor.

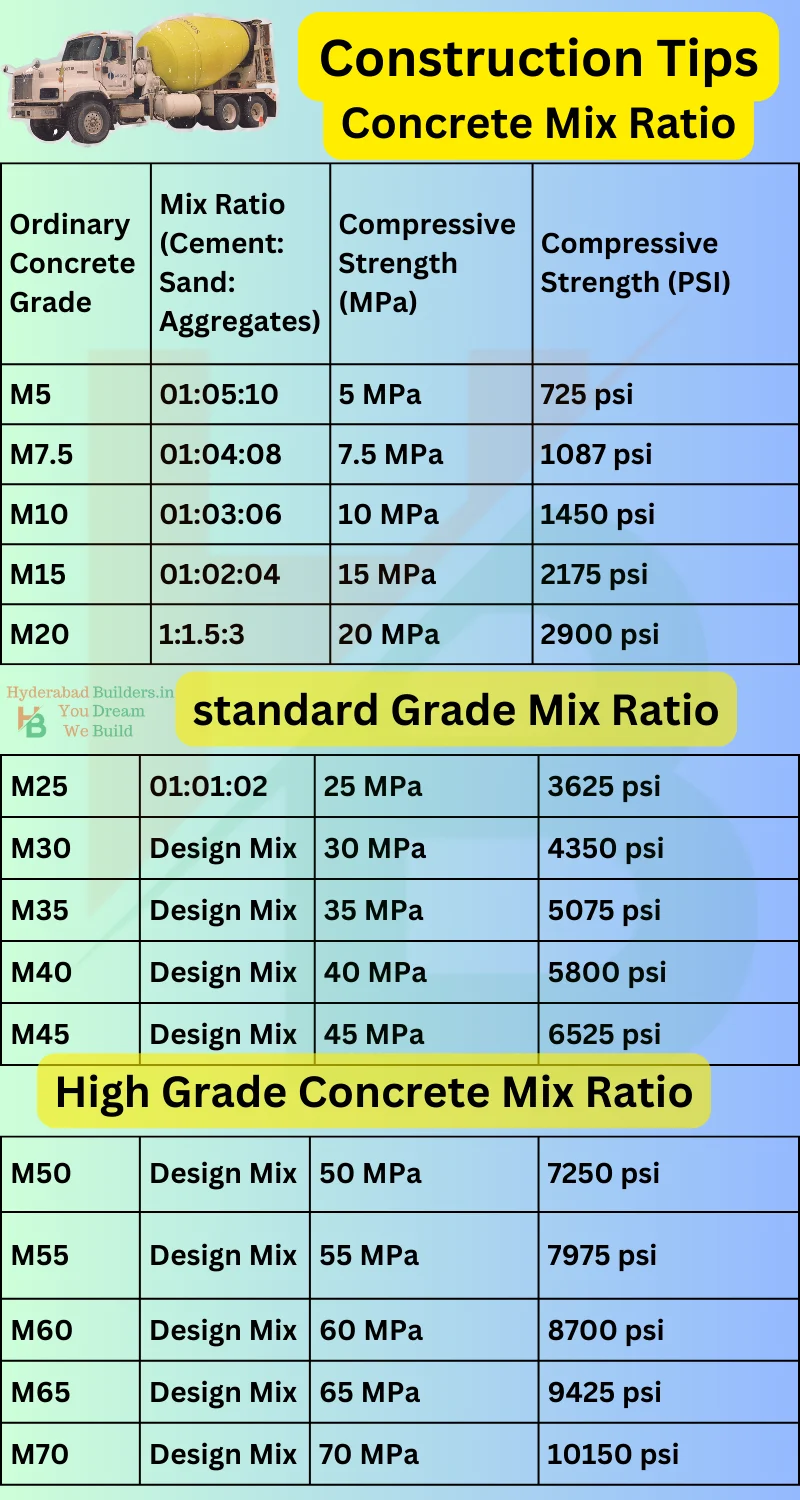

| Concrete Grade | Concrete Mix Ratio (Cement: Sand: Aggregates) | Compressive Strength (MPa) | Compressive Strength (PSI) |

|---|---|---|---|

| M5 | 1:5:10 | 5 MPa | 725 psi |

| M7.5 | 1:4:8 | 7.5 MPa | 1087 psi |

| M10 | 1:3:6 | 10 MPa | 1450 psi |

| M15 | 1:2:4 | 15 MPa | 2175 psi |

| M20 | 1:1.5:3 | 20 MPa | 2900 psi |

| Standard Strength Concrete Grades | |||

| M25 | 1:1:2 | 25 MPa | 3625 psi |

| M30 | 1:0.75:1.5 | 30 MPa | 4350 psi |

| M35 | 1:1.65:2.92 | 35 MPa | 5075 psi |

| M40 | Design Mix | 40 MPa | 5800 psi |

| M45 | 1 : 2.42 : 3.19 | 45 MPa | 6525 psi |

| Standard Strength Concrete GradesHigh Strength Concrete Grades | |||

| M50 | Design Mix | 50 MPa | 7250 psi |

| M55 | Design Mix | 55 MPa | 7975 psi |

| M60 | Design Mix | 60 MPa | 8700 psi |

| M65 | Design Mix | 65 MPa | 9425 psi |

| M70 | Design Mix | 70 MPa | 10150 psi |

Note: Design mix ratios for M30, M40, M45, M50, M55, M60, M65, M70 and other are project-specific and should be determined based on structural requirements. Always consult with a structural engineer for precise mix ratios please like share if you like our article on concrete mix ratio

M10 Design Mix:

- Design Mix Ratio: 1:3:6 (Cement: Sand: Aggregates)

- Compressive Strength: 1,450 PSI

M15 Design Mix:

- Design Mix Ratio: 1:2:4 (Cement: Sand: Aggregates)

- Compressive Strength: 2,175 PSI

M20 Design Mix:

- Design Mix Ratio: 1:1.5:3 (Cement: Sand: Aggregates)

- Compressive Strength: 2,900 PSI

M25 Design Mix ratio:

- 1:1:2 (Cement: Sand: Aggregates)

- Compressive Strength: 3,625 PSI

M30 Design Mix ratio:

- 1:0.75:1.5 (Cement: Sand: Aggregates)

- Compressive Strength: 4,350 PSI

M35 Design Mix ratio:

- 1:1.65:2.92Cement: Sand: Aggregates)

- Compressive Strength: 5,075 PSI

M45 Design Mix ratio:

- 1 : 2.42 : 3.19 (Cement: Sand: Aggregates)

- Compressive Strength: 6,525 PSI

M50 Design Mix:

- Design Mix Ratio: As per project requirements

- Compressive Strength: 7,250 PSI

M55 Design Mix ratio:

- Design Mix Ratio: As per project requirements

- Compressive Strength: 7,975 PSI

M60 Design Mix ratio:

- Design Mix Ratio: As per project requirements

- Compressive Strength: 8,700 PSI

M65 Design Mix:

- Design Mix Ratio: As per project requirements

- Compressive Strength: 9,425 PSI

M70 Design Mix:

- Design Mix Ratio: As per project requirements

- Compressive Strength: 10,150 PSI

The “M” stands for mix, and it indicates the mix ratio of key components like cement, sand, and aggregates. The number following “M” represents the compressive strength of the concrete in megapascals (MPa) at 28 days.

M35 concrete, with a compressive strength of 5,075 PSI and a design mix, is ideal for constructing external walls of commercial buildings due to its high consistency and uniformity.

The mix ratio determines the properties of concrete, including its strength and workability. Different ratios cater to specific construction needs, with variations in strength, durability, and application suitability.

| Concrete Grade | Compressive Strength (PSI) |

|---|---|

| M10 | 1,450 |

| M15 | 2,175 |

| M20 | 2,900 |

| M25 | 3,625 |

| M30 | 4,350 |

| M40 | 5,800 |

| M45 | 6,525 |

| M50 | 7,250 |

| M55 | 7,975 |

| M60 | 8,700 |

| M65 | 9,425 |

| M70 | 10,150 |

Ordinary Grade Concrete (M10-M20): With strengths of 1,450 to 2,900 PSI, these are suited for non-structural purposes like patio slabs, providing a cost-effective option for basic construction.

Standard Concrete (M25-M45): Ranging from 3,625 to 5,800 PSI, this grade is ideal for critical structures such as girders, offering enhanced strength, durability, and consistency.

High-Grade Concrete (M45-M70): With impressive strengths from 6,525 to 10,150 PSI, this grade is employed in high-end projects like dams, ensuring exceptional strength and longevity in critical constructions.