Category: TMT Steel Bars

We at Hyderabad builders offer Today TMT Steel Bars Price list per kg and ton in Hyderabad. We offer various grades steel Fe-415, Fe-500, FE-550, Fe-600.we also offer in different tmt bar sizes 8MM, 10MM, 12MM, 16MM, 20MM, 25MM, 32MM, 40MM

Showing all 4 results

Steel Tmt Bar Price Hyderabad

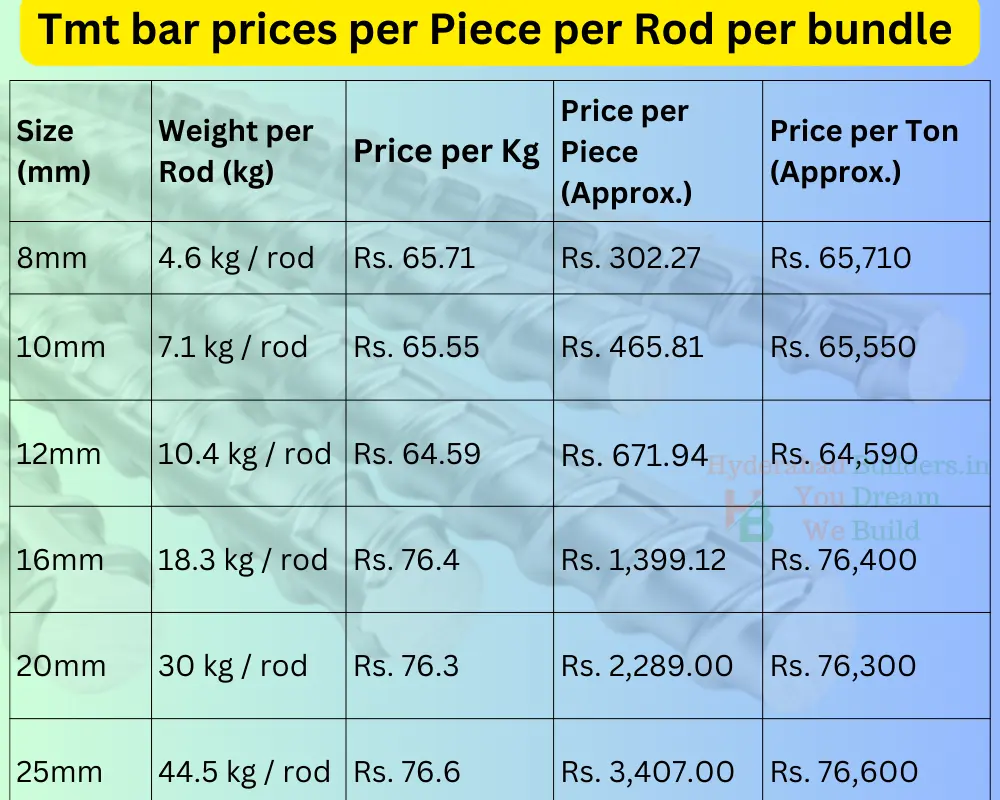

| Steel bar Size (mm) | Weight per Rod (kg) | Price per Kg (Without VAT) | Price per Piece (Approx.) | Price per Ton (Approx.) |

|---|---|---|---|---|

| 6mm | 2.67 kg / rod | Rs. 52.71 per kg | Rs. 140.7357 | Rs. 52,710 |

| 8mm | 4.6 kg / rod | Rs. 65.71 per kg | Rs. 302.27 | Rs. 65,710 |

| 10mm | 7.1 kg / rod | Rs. 65.55 per kg | Rs. 465.81 | Rs. 65,550 |

| 12mm | 10.4 kg / rod | Rs. 64.59 per kg | Rs. 671.94 | Rs. 64,590 |

| 16mm | 18.3 kg / rod | Rs. 76.4 per kg | Rs. 1,399.12 | Rs. 76,400 |

| 20mm | 30 kg / rod | Rs. 76.3 | Rs. 2,289.00 | Rs. 76,300 |

| 25mm | 44.5 kg / rod | Rs. 76.6 | Rs. 3,407.00 | Rs. 76,600 |

Steel Bar Price by Top Steel Companies

| Steel Price by Brand | 8mm Steel Price | 12mm Steel Price | 16mm Steel Price | 20mm Steel Price | 25mm Steel Price |

|---|---|---|---|---|---|

| Tata Tiscon | 73.13 /kg | 71.54 | 70.47 | 70.50 | 70.53 |

| Jindal Panther | 71.88 /kg | 70.16 | 69.44 | 69.38 | 69.41 |

| Birla TMT steel | 72.41/kg | 70.97 | 69.99 | 70.00 | 70.10 |

| JSW Steel | 72.05 /kg | 70.39 | 69.51 | 69.60 | 69.61 |

| Vizag Steel | 75.26 /kg | 74.04 | 73.80 | 73.61 | 73.61 |

| Kamdhenu (PAS 10000) | 72.05 /kg | 70.51 | 69.51 | 69.50 | 69.53 |

| Ultra TMT steel | 73.49/kg | 73.25 | 72.29 | 72.05 | 71.90 |

| SAIL TTT | 67.77 /kg | 66.29 | 65.77 | 65.62 | 65.87 |

| Shyam Steel Bar | 71.70 /kg | 70.51 | 69.75 | 69.77 | 69.82 |

| SRMB Steel Bar | 71.52 /kg | 70.16 | 69.27 | 69.38 | 69.50 |

| Essar TMT | 72.21 /kg | 72.21 | 71.78 | 71.78 | 71.78 |

| Radha TMT | 65.80 /kg | 65.49 | 64.42 | 64.77 | 64.75 |

| SEL Tiger TMT | 69.37 /kg | 68.11 | 67.84 | 67.81 | 67.84 |

Length of steel Tmt bar in Meters, Feet, Inches

- Length of TMT bar in meters: 12 meters

- Length of tmt bar in feet: 39.37008 feet

- tmt bar lenth in inches: 472.44096 inches

Why is it important to know current tmt bar price before placing order

Cost Estimation: Knowledge of the current TMT bar price facilitates accurate cost estimation for construction projects. This information allows project planners to develop realistic budgets, ensuring that expenses are adequately accounted for and potential cost overruns are minimized.

Budget Management: Understanding the TMT bar price today enables effective budget management throughout the duration of a construction project. Project managers can monitor price fluctuations and adjust spending plans as needed to maintain financial discipline and avoid exceeding allocated budgets.

Supplier Negotiations: Armed with up-to-date pricing information, construction builders and home owners can negotiate more effectively with suppliers. Knowledge of prevailing TMT bar prices empowers buyers to secure favorable terms, discounts, or bulk pricing arrangements, optimizing procurement costs, transportation cost and enhancing project profitability.

Financial Planning: Accurate knowledge of the TMT bar price is essential for financial planning and risk assessment in construction projects. Lenders, investors, and financial institutions like bank and nbfc rely on detailed cost projections, including the TMT bar price today, to evaluate project feasibility and assess potential returns on investment.

Market Awareness: Tracking the steel rate today provides valuable insights into market trends and economic conditions. Awareness of market dynamics allows stakeholders to anticipate price movements, adapt to changing market conditions, and make informed decisions about project timing and execution.

Tmt bar Sizes and weight no of rods per bundle

| Tmt bar Sizes | Weight per Rod (kg) | No. of Rods per Bundle | Weight per Bundle (kg) | Bundles per Ton (approx.) |

|---|---|---|---|---|

| 8 mm | 4.6 | 10 rods | 45 to 46 | 22 |

| 10 mm | 7.1 | 7 rods | 49 to 50 | 20 |

| 12 mm | 10.4 | 5 rods | 51 to 52 | 20 |

| 16 mm | 18.3 | 3 rods | 54 to 56 | 18 |

| 20 mm | 30 | 2 rods | 58 to 60 | 17 |

| 25 mm | 44 to 48 | 1 rod | 44 to 46 | 22 |

Formula to calculate Tmt bars weight

The formula provided to calculate the weight of TMT bars is based on the cross-sectional area of the bar. Here’s a breakdown of how it works:

-

Formula for mass per bar per square meter:

- Formula: Mass = (D * D) / 162

- Where D is the diameter of the TMT bar in millimeters.

- Example: For a 8 mm TMT bar, the mass would be (8 * 8) / 162 = 0.369 kg.

-

Formula for weight of a single TMT bar:

- Formula: Weight = (D * D * L) / 162

- Where D is the diameter of the TMT bar in millimeters, and L is the length of the bar in meters.

- Example: For a 8 mm TMT bar with a length of 12 meters, the weight would be (8 * 8 * 12) / 162 = 4.74 kg.

This formula accounts for the density of steel and the cross-sectional area of the TMT bar. It’s essential to ensure consistency in weight, and the formula helps in adhering to the IS:1786-2008 standard.

TMT Steel Bars: Features, Properties, Benefits, and Applications

Thermo Mechanical Treatment (TMT) steel bars are key component in the construction industry, renowned for their exceptional properties and numerous advantages. This comprehensive guide explores the various aspects of TMT steel bars, including their features, properties, benefits, and applications.

What is the Full Form of TMT

TMT stands for Thermo Mechanical Treatment, a specialized process used in the manufacturing of steel bars to enhance their mechanical properties.

Tmt bar Features and Properties

TMT steel bars exhibit a range of features and properties that make them indispensable in construction projects:

- High Ductility: TMT bars possess high ductility, allowing them to withstand bending and stretching without breaking.

- Flexibility: They offer excellent flexibility, making them suitable for various structural configurations.

- Corrosion Resistance: TMT bars are highly resistant to corrosion, ensuring longevity and durability in diverse environments.

- Tensile Strength: These bars have impressive tensile strength, providing robust support to structures.

- Shockproof: TMT bars are shockproof, making them suitable for earthquake-prone regions.

- Long-lasting: With their anti-corrosion properties, TMT bars have a long lifespan, reducing maintenance costs over time.

- Easy to Transport and Weld: Their ease of transport and weldability contribute to efficient construction processes.

Tmt Bar Grades

TMT bars are available in various steel grades, each offering different levels of tensile strength:

- Fe 415

- Fe 500

- Fe 550

- Fe 600

Earthquake Resistance

TMT bars are renowned for their earthquake-resistant properties, providing structural stability during seismic events.

Tmt bar Manufacturing Process

The manufacturing process of TMT bars involves several stages, including:

- Processing raw iron ore

- Converting iron to steel

- Thermo Mechanical Treatment & Hot Rolling

Rustproof Nature

TMT bars are highly rust-resistant, ensuring structural integrity and longevity even in corrosive environments.

Cost Comparison

While TMT bars may be more expensive than regular steel bars, their long-term benefits justify the initial investment.

Suitability for Large-Scale Construction

TMT bars are ideal for large-scale commercial construction projects due to their superior properties and reliability.

Availability

TMT bars are manufactured by leading steel companies, emphasizing the importance of buying from trusted sources to ensure quality and authenticity.

Finding FE 550 and FE 500D TMT Bars

These specific grades of TMT bars can be found at reputable manufacturers who adhere to industry standards and quality controls.

Additional Points

In addition to the core features and properties, TMT steel bars offer several other advantages:

-

- Bond Strength: Excellent bond strength with concrete ensures structural stability.

- Weldability: Highly weldable, allowing for easy customization.

- Uniformity: Precise dimensions and uniformity throughout the length of the bar.

- Sustainability: Environmentally friendly, recyclable, and reusable.

- Fire Resistance: High resistance to fire enhances safety.

- Certifications: Look for TMT bars meeting relevant standards and certifications.

- Quality Control: Reputable manufacturers implement stringent quality control measures.

- Technical Support: Leading manufacturers offer technical assistance and guidance.

- Innovation: Ongoing research leads to continuous improvements in TMT bar technology.

- Case Studies: Explore real-life examples demonstrating the effectiveness of TMT bars in construction.

Where do Tmt bars are used ?

TMT bars find extensive use in various construction projects due to their exceptional properties and benefits. Here are some common applications of TMT bars in construction:

- Building Construction: TMT bars are widely used in the construction of residential, commercial, and industrial buildings for structural reinforcement. They provide the necessary strength and stability to support the building’s framework and withstand loads such as gravity, wind, and seismic forces.

- Precast Walls and Boundary Walls: TMT bars are commonly used in the construction of precast walls and boundary walls. In precast wall panels, TMT bars provide structural reinforcement, ensuring the walls can withstand external loads and environmental forces. Additionally, TMT-reinforced precast walls offer durability and longevity, making them suitable for various applications such as boundary walls for residential, commercial, and precast boundary walls for agricultural lands settings. These walls provide security, privacy, and delineation of property boundaries, contributing to the overall functionality and aesthetics of the built environment.

- Bridges and Flyovers: TMT bars are essential components in the construction of bridges, flyovers, and elevated roadways. These structures require robust reinforcement to bear heavy traffic loads and resist dynamic forces, making TMT bars an ideal choice.

- Dams and Hydroelectric Projects: In dam construction and hydroelectric projects, where structures are subjected to high water pressure and environmental stresses, TMT bars play a critical role in providing structural integrity and durability.

- High-Rise Buildings: TMT bars are indispensable in the construction of high-rise buildings and skyscrapers, where the structural framework must withstand vertical and lateral loads. Their high tensile strength and ductility make them suitable for tall and complex structures.

- Industrial Structures: TMT bars are used in the construction of industrial facilities such as factories, warehouses, and manufacturing plants. These structures require sturdy reinforcement to support heavy machinery, equipment, and industrial processes.

- Infrastructure Projects: TMT bars are essential in infrastructure projects such as roads, tunnels, railways, and airports. They reinforce concrete structures, including pavements, retaining walls, culverts, and tunnels, ensuring their stability and longevity.

- Seismic Zones: In earthquake-prone regions, TMT bars are preferred for their superior earthquake resistance. They help mitigate the impact of seismic forces, reducing the risk of structural damage and collapse during earthquakes.

- Residential Construction: TMT bars are used in the construction of individual houses, apartments, and residential complexes to reinforce columns, beams, slabs, and foundations. They enhance the structural stability and safety of residential buildings.

- Public Infrastructure: TMT bars are utilized in the construction of public infrastructure projects such as schools, hospitals, government buildings, and recreational facilities. These structures require durable reinforcement to ensure public safety and functionality.

- Renovation and Retrofitting: TMT bars are also employed in renovation and retrofitting projects to strengthen existing structures and improve their load-bearing capacity, especially in older buildings and heritage sites.

List of Top TMT Bar companies in India

- JSW Steel

- Tata Steel

- Hindalco Industries Limited

- Kasteel

- Essar Steel

- Rashtriya Ispat Nigam Limited (RINL)

- Jindal Steel and Power Limited

- Steel Authority of India Limited (SAIL)

- Prime Gold Group

- Bhushan Steel

What is a TMT Bar?

How are TMT Bars Manufactured?

Why Choose TMT Bars for Construction?

Why Do TMT Bars Have a Unique Rib Pattern?

What are the Main Types of Stainless Steel?

Why Reinforce Cement with TMT Bars in Construction?

What Factors Matter Before Choosing a TMT Bar?

How Many Grades of TMT Bars are Available?

How to Check the Quality of TMT Bars?

What are the Uses of TMT Bars?