M35 Mix Design Ratio for Pile Foundations

Table of Contents

ToggleIntroduction

M35 Grade Concrete: M35 represents the comprehensive strength of the concrete, and in this case, it is 35 MPa. The design involves understanding the specific requirements, adjusting for site conditions, and ensuring the mix meets the necessary criteria for pile foundations.

Key Parameters:

– Comprehensive Strength (Fck): 35 MPa

– Standard Deviation: 1.91 MPa

– Target Mean Strength (T.M.S.): 38.15 MPa

Test Data for Material

Aggregate Type and Specific Gravity

– Aggregate Type: Crushed

– Specific Gravity:

– Cement: 3.15

– Coarse Aggregate: 2.67

– Fine Aggregate: 2.62

Sand Content

Taking the sand content as a percentage of total aggregates, it is set at 36%.

Water-Cement Ratio M35 concrete ratio

The water-cement ratio is a crucial factor in determining the mix design. For M35 grade concrete, a water-cement ratio of 0.43 is chosen, as per IS 10262-1982.

Water Content

Following the guidelines from IS: 10262, the water content is selected as 172 kg, ensuring it aligns with the specified maximum water content for 20 mm nominal size of aggregates.

Cement Content Calculation

The cement content is calculated using the water-cement ratio:

Cement Content = Water Content / Water-Cement Ratio = 172 / 0.43 = 400 kg/m³

Mix Proportions for Fine and Coarse Aggregate

The mix proportions are calculated using the formula for fine and coarse aggregate, considering the specific gravity of the materials and air content:

1000(1-a₀) = ((Cement Content / Sp. Gr. Of Cement) + Water Content + (Fa / Sp. Gr. * Pf)) / ((Cement Content / Sp. Gr. Of Cement) + Water Content + (Ca / Sp. Gr. * Pc))

The resulting fine aggregate (Fa) and coarse aggregate (Ca) are found to be 642 kg/m³ and 1165 kg/m³, respectively.

Gradation of Coarse Aggregates

Based on the combined gradation, a proportion of 53:47 for 20 mm and 10 mm aggregates produces the best gradation as per IS: 383.

20 mm Aggregates: 619 kg/m³

10 mm Aggregates: 546 kg/m³

Admixture

To achieve the desired slump in the range of 150-190 mm, a water-reducing admixture (SP430 from Fosroc) is recommended. The dosage is set at 0.3% by weight of cement.

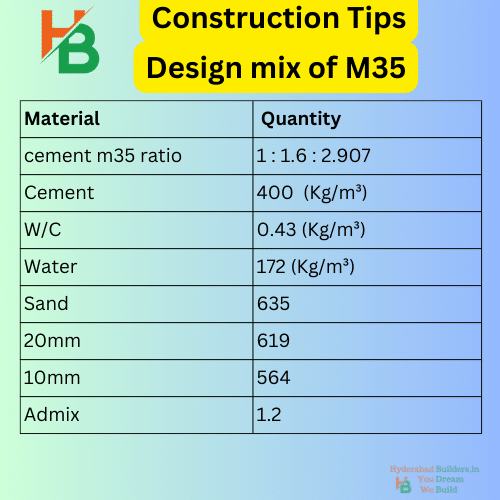

M35 Mix Design Ratio Table

| Material | Quantity |

|---|---|

| Cement (M35 Ratio) | 1 : 1.6 : 2.907 |

| Cement | 400 Kg/m³ |

| W/C | 0.43 Kg/m³ |

| Water | 172 Kg/m³ |

| Sand | 635 Kg/m³ |

| 20mm | 619 Kg/m³ |

| 10mm | 564 Kg/m³ |

| Admixture | 1.2 |

Conclusion

A meticulous mix design is crucial for the success of any concrete construction, especially for critical elements like pile foundations. The M35 grade concrete mix design outlined here considers various factors, ensuring the resulting concrete meets strength, durability, and workability requirements. However, it’s essential to note that on-site conditions and specific project requirements may necessitate adjustments to the mix design.

In conclusion, a well-designed concrete mix not only ensures the structural integrity of the project but also contributes to the longevity and performance of the structure over time.

Related article : Mix design ration M45, Mix design ratio of m40, mix design ratio of M20

Disclaimer: The provided mix design details are for reference. Site conditions may necessitate adjustments.