Decoding TMT Bar Sizes chart In India

Table of Contents

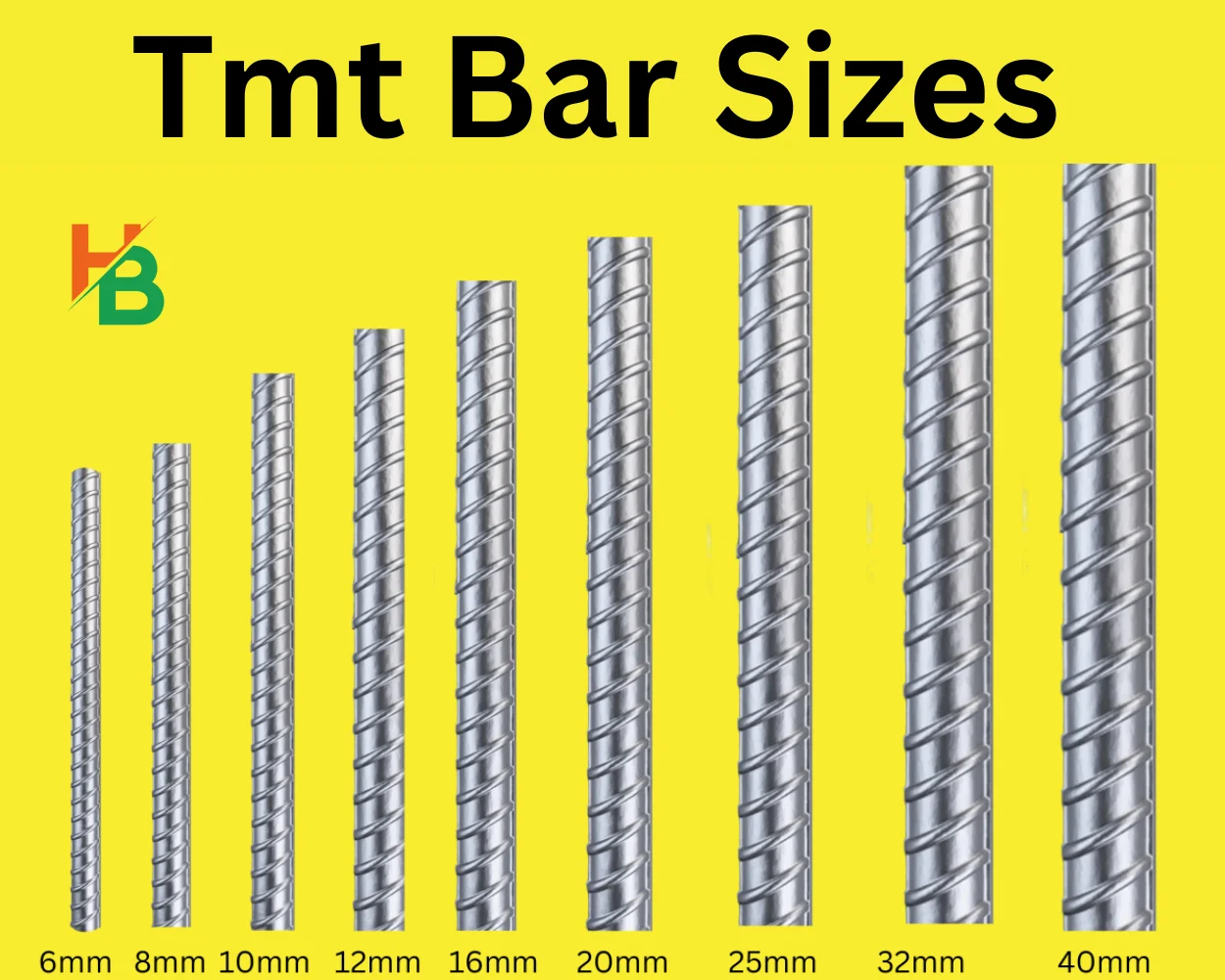

ToggleIn the intricate world of construction, the choice of building materials holds the key to creating structures that stand strong against the test of time. Thermo-Mechanically Treated (TMT) bars, known for their strength and durability, come in a variety of sizes. From the slender 6mm to the robust 40mm, each TMT bar size serves a specific purpose in the construction of buildings and infrastructure. Let’s unravel the significance of different TMT bar sizes in construction.

6mm and 8mm TMT Bars:

Characteristics:

- Smaller diameter for flexibility and ease of handling.

- Ideal for light construction work.

Applications:

- Residential projects benefit from these bars in constructing slabs, balconies, and other non-load-bearing structures.

- Their smaller size makes them suitable for intricate construction needs, ensuring precision in smaller-scale projects.

10mm and 12mm TMT Bars:

Characteristics:

- Increased diameter for improved load-bearing capacity.

- Versatile and suitable for small to medium-sized construction projects.

Applications:

- Commonly used in residential buildings for creating beams, columns, and load-bearing structures.

- Offer a balance between strength and flexibility, making them integral in various structural elements.

16mm and 20mm TMT Bars:

Characteristics:

- Stepping into heavier construction requirements.

- Enhanced strength for load-bearing components.

Applications:

- Employed in the construction of mid-sized buildings and structures.

- Used for crucial load-bearing elements like columns and beams, providing the necessary strength and durability.

25mm and 32mm TMT Bars:

Characteristics:

- Larger diameter for robustness.

- Ideal for high-rise buildings and infrastructure projects.

Applications:

- Staple in the construction of tall structures, providing the necessary strength to withstand heavy loads.

- Ensures structural stability in larger and more complex projects.

40mm TMT Bars:

Characteristics:

- Reserved for projects demanding the utmost strength.

- Used in critical load-bearing elements of massive structures.

Applications:

- Essential in projects like bridges, industrial buildings, and high-rise complexes.

- Ensures structural integrity and durability in large-scale constructions where strength is paramount.

TMT Bar Sizes and Applications

| TMT Bar Sizes | Applications |

|---|---|

| 6mm and 8mm | Light construction work, residential projects for slabs, balconies, and non-load-bearing structures. |

| 10mm and 12mm | Small to medium-sized construction projects, residential buildings for beams, columns, and load-bearing structures. |

| 16mm and 20mm | Mid-sized buildings and structures, load-bearing elements like columns and beams. |

| 25mm and 32mm | High-rise buildings, infrastructure projects, ensuring structural stability in larger and complex projects. |

| 40mm | Projects demanding utmost strength, critical load-bearing elements of massive structures like bridges and industrial buildings. |

Choosing the Right TMT Bar Sizes: Considerations for Builders

Selecting the appropriate TMT bar size is a crucial decision that builders and engineers need to make based on the specific demands of a construction project. Here are key considerations:

- Structural Design: Follow the structural design specifications provided by architects and engineers. The design will dictate the sizes required for different structural elements.

- Load-Bearing Requirements: Assess the load-bearing capacity needed for different parts of the structure. Larger diameter TMT bars are suitable for components bearing heavier loads.

- Building Codes and Standards: Adhere to local building codes and standards that prescribe the minimum requirements for TMT bar sizes in construction projects.

- Project Scale: Consider the scale and purpose of the construction project. Residential projects may require smaller sizes, while large-scale infrastructure projects demand larger diameters.

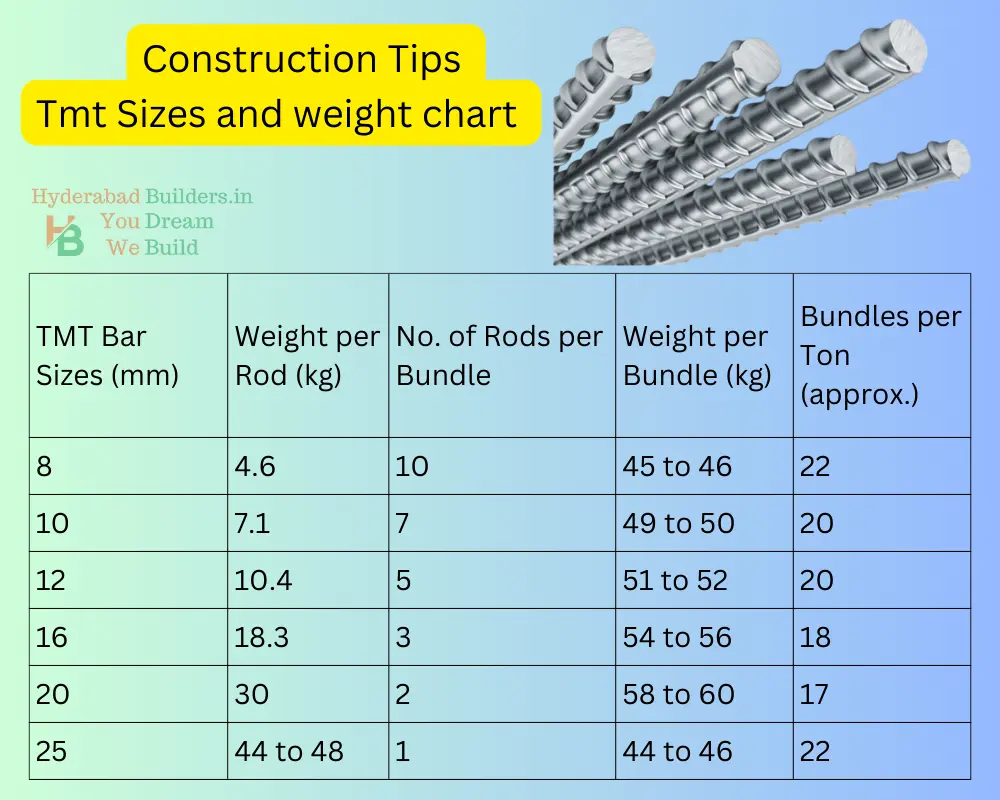

TMT bar Weight chart

TMT Bar Sizes and Applications

Conclusion

In the realm of construction, the spectrum of TMT bar sizes offers a versatile toolkit for builders to craft structures that endure and excel. As construction practices evolve, the strategic selection of TMT bar sizes will remain pivotal in ensuring the resilience and longevity of diverse structures across urban landscapes.

For builders and construction professionals, mastering the art of choosing the right TMT bar size is akin to unlocking the full potential of a construction project, ensuring it stands tall, strong, and steadfast against the forces of time and nature.

TMT bars, or Thermo-Mechanically Treated bars, are steel bars widely used in construction for their strength and durability. The manufacturing process involves heat treatment to create a tough outer core and a softer inner core

TMT bars come in various sizes, ranging from 6mm, 8mm, 10mm, 12mm, 16mm, 20mm, 25mm, 32mm,40mm in diameter. Each size serves a specific purpose in construction, from light residential projects to heavy infrastructure development.

These smaller diameter TMT bars (6mm and 8mm) are ideal for light construction work. They find applications in residential projects for constructing slabs, balconies, and other non-load-bearing structures.

Well-suited for small to medium-sized construction projects, 10mm and 12mm TMT bars are commonly used in residential buildings for creating beams, columns, and other load-bearing structures.

Stepping into heavier construction requirements, 16mm and 20mm TMT bars are employed in the construction of mid-sized buildings and structures. They offer enhanced strength for load-bearing components like columns and beams.

Larger diameter TMT bars (25mm and 32mm) are a staple in the construction of high-rise buildings and infrastructure projects. They provide the necessary robustness for withstanding heavy loads and ensuring structural stability.

Reserved for projects demanding the utmost strength, 40mm TMT bars are used in critical load-bearing elements of massive structures such as bridges, industrial buildings, and high-rise complexes.

Consider the structural design specifications provided by architects and engineers, assess the load-bearing requirements, adhere to local building codes and standards, and factor in the scale and purpose of the construction project.

The strategic selection of TMT bar sizes is pivotal in ensuring the resilience and longevity of diverse structures. It impacts the overall strength, stability, and load-bearing capacity of the constructed edifice.

As construction practices evolve, the strategic selection of TMT bar sizes will continue to play a vital role in crafting structures that endure and excel in diverse urban landscapes