How Bricks are made

Table of Contents

ToggleThe brick manufacturing industry, though rooted in timeless principles, has undergone transformative changes propelled by technological advancements. While the fundamentals remain unaltered, contemporary brick plants demonstrate increased efficiency and enhanced product quality.

Lets dive in to the process how bricks are made and what raw material requires and and what is the step by step brick manufacturing process. the are different type of bricks each has its own manufacturing process the type of manufacturing we choose to manufacture will have effect on both price of bricks and on environment also. Today the brick price in Hyderabad,India is Rs 9.50 Inr/ piece for 1000 bricks price is around Rs 9,500 INR this is standard quality brick price As per Invest India and IBEF, the construction Industry in India is expected to become the 3rd largest construction market globally and to reach USD 1.4 trillion by 2025. Moreover, Real Estate Industry in India is expected to reach USD 1 trillion by 2030 and will contribute to around of% to India’s GDP

Raw Materials required in Brick Manufacturing

Clay as the Foundation: At the heart of brick manufacturing lies clay, an abundant and naturally occurring mineral on Earth. However, not all clays are interchangeable; they must meet specific criteria to be suitable for brick production. Key attributes include plasticity, the capacity to be shaped or molded when mixed with water, ample strength to retain form, and the ability to fuse at elevated temperatures.

Categorizing Clay Varieties: Clays come in various forms, with three primary categories: surface clays, shales, and fire clays. Surface clays, found near the Earth’s exterior, may be upthrusts of older deposits or more recent sedimentary formations. Shales, subjected to high pressures, nearly harden into slate. Fire clays, mined at deeper levels, boast refractory qualities.

Shale:

- Another essential raw material, shale contributes distinct properties to bricks. It is often blended with clay to achieve specific characteristics.

Fire Clays:

- Fire clays are used in brick manufacturing for their ability to withstand high temperatures during firing. They are one of the categorized types of clays.

Water:

- Water is crucial in the manufacturing process, especially during the preparation phase. It is added to clay to achieve plasticity and facilitate the forming process.

Engobes (Clay Slurries):

- Finely ground clay or colorants in the form of engobes are applied to the brick surface during manufacturing to create textures, coatings, and distinctive patterns.

Colorants:

- Various colorants, including iron for red hues, are naturally present in clays. The firing process and kiln control also influence the final color of the bricks.

Concrete (for Concrete Bricks):

- In the case of concrete bricks, cement, aggregates, and other additives are used along with water to form the brick.

Sand (for Sand-Lime Bricks):

- Sand is a key component in the production of sand-lime bricks, contributing to their composition and characteristics.

Fly Ash (for Fly Ash Bricks):

- Fly ash, a waste product from coal combustion, is used in the manufacturing of fly ash bricks.

Lubricants:

- Lubricants derived from processing organic materials are used in the forming process to prevent clay from sticking to molds.

- Sawdust (as Burnout Material):

- Sawdust is sometimes used as a burnout material in the firing process, contributing to the environmental efficiency of brick manufacturing

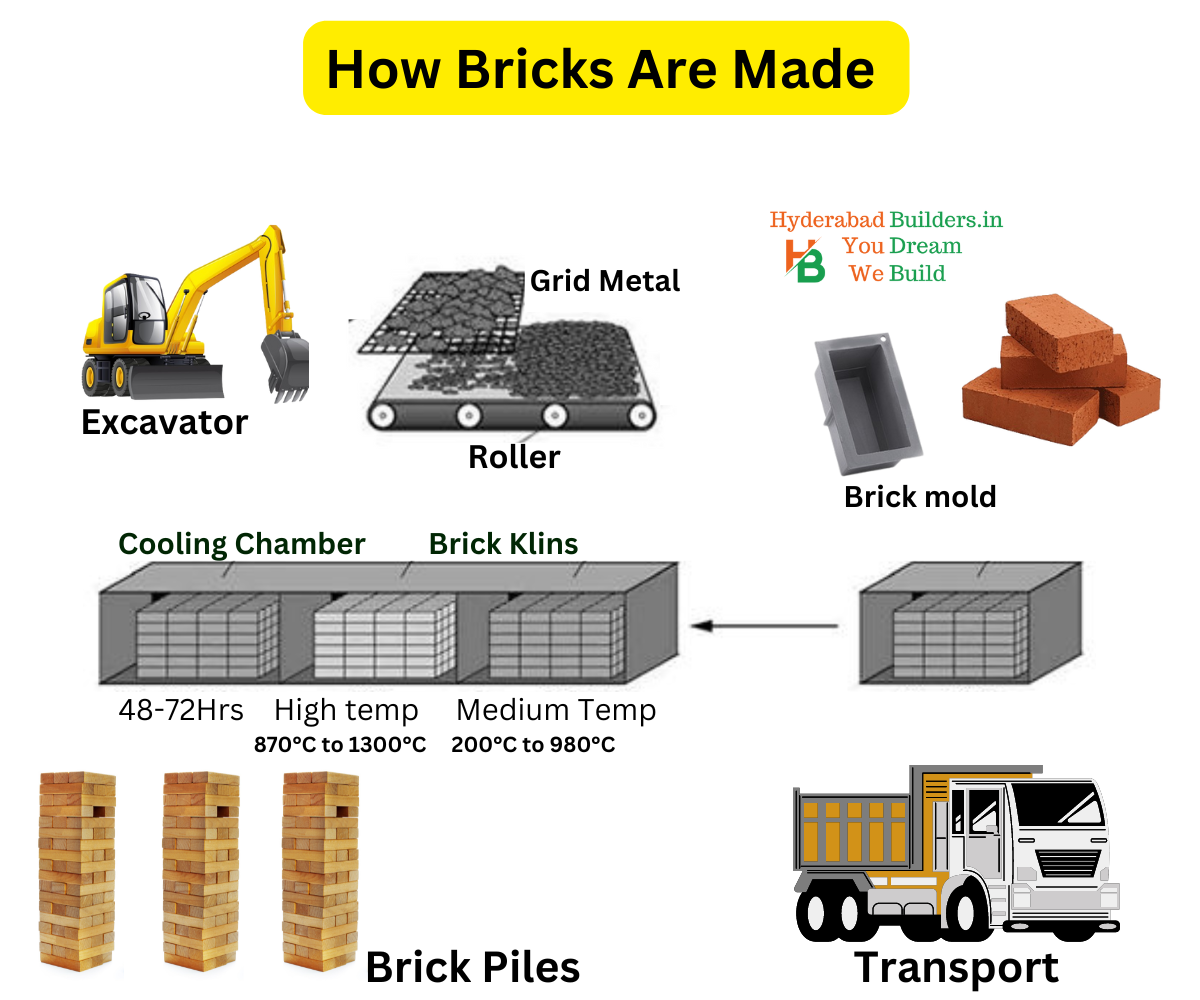

How bricks are made?

Clay Collection: Suitable clay is gathered from natural deposits or mines. It should have the right composition and texture.

Weathering: The clay is left to weather, exposed to the elements, which helps improve its plasticity and workability.

Preparation: The clay is mixed with water to form a workable consistency, sometimes adding sand or other materials for better strength.

Molding: The clay is shaped into brick forms using molds. It can be done by hand or using machinery.

Drying: The molded bricks are allowed to air-dry, reducing moisture content.

Firing: Bricks are fired in kilns at high temperatures, ranging from 1,000 to 2,000 degrees Celsius, turning them into durable, solid units.

Cooling: After firing, bricks are left to cool gradually, ensuring strength and durability.

The final product, shaped and solidified, emerges as durable and versatile building blocks. In the late 19th century, contemporary U.S. brick production predominantly relies on mechanization.

Step by step bricks manufacturing process

Mining and Storage: Unearthing the Foundation The journey of brick creation commences with the extraction of surface clays, shales, and specialized fire clays from open pits, utilizing robust power equipment. These raw materials, brimming with potential, are then meticulously transported to designated storage areas within the manufacturing plant. The strategic storage not only ensures a continuous production flow, regardless of weather conditions but also facilitates blending, a crucial step for achieving uniformity, controlling color variations, and meeting specific brick body requirements.

Preparation: Shaping the Raw Potential Before the alchemy of brick formation begins, large clay lumps and stones undergo a transformative size reduction. This critical preparation step involves the precise processing of materials through inclined vibrating screens, an intricate dance that regulates particle size. This meticulous preparation sets the stage for the subsequent phases of the manufacturing process.

- Forming the Brick: Crafting Excellence The heart of the manufacturing process beats within the forming phase, where clay transforms into the iconic brick shapes. Three primary processes govern this phase:

- Stiff-Mud Extravaganza: Approximately 90% of U.S. brick production unfolds through the stiff-mud process. Clay is extruded, de-aired in a vacuum chamber, and meticulously cut to precision. This intricate dance enhances workability, plasticity, and strength.

- Soft-Mud Elegance: Embracing clays with higher water content, the soft-mud process involves molding the clay in lubricated molds. The result? Exquisite brick forms, each a testament to the adaptability of the manufacturing process.

- Dry-Press Precision: Suited for low-plasticity clays, the dry-press process employs minimal water. Hydraulic or compressed air rams then press the clay into steel molds, showcasing precision and efficiency.

Drying: From Wet to Solid Wet bricks, embodying 7 to 30 percent moisture contingent on the forming method, undergo a delicate drying phase. Within dedicated chambers, temperatures ranging from 100 ºF to 400 ºF guide the bricks through a 24 to 48-hour metamorphosis. Careful regulation of heat, often harnessed from kiln exhaust, ensures the bricks emerge with structural integrity, free from the cracks that may mar their potential.

Hacking and Firing: The Crucible of Transformation Hacking, a choreographed loading of kiln cars often orchestrated by robots, precedes the transformative crucible of firing. In kilns, the bricks undergo a carefully orchestrated journey lasting 10 to 40 hours, contingent on kiln type. The temperature stages, akin to an artisan’s strokes on canvas, include final drying, dehydration, oxidation, vitrification, and an optional flashing encore for those seeking color variation in the final masterpiece.

Cooling and De-hacking: From Blaze to Tranquility As the kiln reaches its zenith, the bricks embark on a cooling sojourn, a process extending up to 10 hours. De-hacking, a symphony of unloading cooled bricks, is often choreographed by robotic virtuosos. Sorted, graded, and elegantly packaged, the bricks stand ready for their final act—distribution. They predominantly don self-contained, strapped cubes, each a testament to the industry’s commitment to ease of handling.

In this intricate ballet of mining, shaping, drying, firing, and refining, how bricks are made emerges not just as a construction material but as a crafted ode to the synthesis of art and science. Each phase, a nuanced chapter, contributes to the enduring legacy of brick in the built environment.

Properties of Bricks

The inherent qualities of bricks, woven intricately into their raw material composition and the manufacturing process, yield an array of properties that define their durability, appearance, and structural integrity. Manufacturers deftly blend different clays, meticulously control the firing process, and employ bricks quality checks to ensure a harmonious symphony of properties in the finished product.

Durability: Durability stands as a cornerstone property, with incipient fusion and partial vitrification during firing serving as pivotal factors. Predictors of durability, such as compressive strength and absorption, are intertwined with firing temperatures. The interplay of these properties, alongside the saturation coefficient, forms a nexus of reliability in brick specifications. However, recognizing variations due to raw materials and manufacturing methods is essential, preventing a one-size-fits-all approach.

Color Dynamics: The color palette of fired clay emerges from a complex dance between chemical composition, firing temperatures, and firing control methods. Iron, a prominent player among the oxides in clays, casts its influence, manifesting red hues in oxidizing fires and dark or black tones in reducing atmospheres. Firing temperatures, absorption values, and compressive strength intermingle to give rise to a spectrum of colors. Notably, the relationship between color and other properties is nuanced, varying across different raw materials.

Texture, Coatings, and Glazes: Textures, an aesthetic facet, arise from the molding and forming processes. Die skins, engobes, and various treatments post-extrusion shape the tactile experience. Engobes, fired clay slips, lend unique patterns, while glazes, either single-fired or double-fired, introduce a layer of impervious protection and a kaleidoscope of colors. Manufacturers, wielding tools that cut, scratch, roll, or brush, sculpt diverse textures, elevating bricks beyond mere structural elements to artful expressions.

Size Variation and Shrinkage: Size variation, an inevitable outcome of clays’ shrinkage during drying and firing, is managed within specified ranges. Drying shrinkage and firing shrinkage, unique to different clays, are carefully navigated to achieve uniform sizes. Though absolute uniformity remains an elusive goal due to natural variations in raw materials and kiln temperatures, controlled factors mitigate excessive variations. Specifications acknowledge and accommodate permissible size variations, recognizing the dynamic nature of the manufacturing process.

Compressive Strength and Absorption: Both compressive strength and absorption, pivotal indicators of structural robustness and moisture absorption, are influenced by clay properties, manufacturing methods, and firing degrees. Higher firing temperatures correlate with elevated compressive strength and reduced absorption. The delicate balance lies in the synergy between manufacturing and firing techniques and the inherent qualities of raw materials, emphasizing the role of clay composition in determining these critical properties.

Environmental Stewardship in Brick Manufacturing: A Commitment to Sustainability

Efficient Resource Utilization: Brick manufacturing stands out as a beacon of efficiency, utilizing materials to produce a product with minimal waste. Proximity to raw material sources ensures that processed clay and shale, removed during forming before firing, seamlessly rejoin the production cycle. Even bricks not meeting standards after firing find purpose, either as grog in manufacturing or as crushed material for landscaping. This circular approach leaves virtually no raw material wasted, embodying sustainability at its core.

Clay: An Abundant Resource: Clay, the primary ingredient in brick production, has been rightfully deemed an “abundant resource” by authorities, dispelling concerns of depletion. Brick manufacturing also integrates nonhazardous waste from diverse industries, demonstrating a commitment to sustainable practices. Utilizing waste products such as bottom- and fly-ash from coal-fired generators, other ceramic materials as grog, lubricants from organic material processing, and sawdust as burnout material underscores the industry’s resourcefulness.

Water Conservation: While water plays a role in brick manufacturing, the industry actively seeks ways to minimize its use. Recirculating and reusing water through storage tanks significantly reduces the demand for potable water. Continuous efforts to enhance water efficiency, illustrated in plants utilizing storage tanks for recirculated water, showcase a dedication to environmental responsibility.

Diversification of Energy Sources: While natural gas remains a prevalent energy source, the industry champions the use of alternative and waste products for brick firing. Methane gas from landfills and sawdust represent viable alternatives, aligning with the industry’s goal of resource reduction and sustainability.

Compliance with Environmental Regulations: The brick industry recognizes the paramount importance of complying with state and federal regulations for clean air and environmental conservation. Robust control measures, such as scrubbers on kiln exhausts, minimize air emissions. Dust control within plants is meticulously managed through filtering systems, vacuums, additives, and water mists. Reclamation efforts in mined areas, including the replacement of overburden and topsoil, ensure the restoration of land for diverse purposes.

Time-Tested Sustainability: With manufacturing processes remaining true to their essence for over 3500 years, brick has demonstrated its safety, durability, and sustainability. The long service life of brickwork stands as a testament to its role in constructing sustainable structures and pavements, contributing significantly to environmental stewardship.

Commitment to Environmental Excellence: Embracing a forward-looking environmental policy, the Brick Industry Association underscores its commitment to stewardship. The policy advocates continual exploration of innovative, environmentally friendly practices in manufacturing and end-use applications. From energy efficiency and recyclability to low maintenance and minimal environmental impact, the industry pledges to produce products that align with the principles of sustainability. Committed to exceeding environmental regulations, the industry collaborates with building professionals to foster environmentally responsible living and working spaces for present and future generations.

Quick summary of Brick Manufacturing

Brick, a durable ceramic product, is crafted from clay or shale through a meticulous process involving formation, drying, and firing, adhering to stringent ASTM standards. The manufacturing process offers variations that are artfully addressed, resulting in a robust final product.

Formation Techniques: There are three primary methods for shaping bricks: extrusion (stiff mud), molding (soft mud), and dry-pressing. The extrusion method, constituting the majority of brick production, involves pushing clay through a die to form the desired shape.

Texture Dynamics: The chosen method of forming significantly influences the texture of the brick. Molded bricks commonly exhibit sand-finished surfaces, while extruded bricks offer a diverse range of textures. The method becomes a defining factor in the aesthetic appeal of the final product.

Colorful Permanence: Brick derives its color either from the minerals in the fired clay or through coatings applied before or after the firing process. This ensures a lasting and resilient color that stands the test of time, resisting fading or diminishing.

Size Variability: The manufacturing journey involves shrinkage as vitrification takes place, resulting in variations in brick size. Despite this inherent variability, brick manufacturers carefully control and mitigate these size differences, ensuring quality and uniformity.

Sustainability Focus: The brick industry demonstrates a commitment to sustainability through strategic choices. Manufacturing facilities are strategically located near clay sources to minimize transportation, process waste is recycled, mined areas are reclaimed, and measures are taken to reduce plant emissions. The majority of bricks find usage within 500 miles of manufacturing facilities, emphasizing local and sustainable practices

Traditional brick-making involves collecting suitable clay, allowing it to weather for improved workability, mixing it with water, molding it into brick shapes, and air-drying the bricks. Subsequently, the molded bricks undergo a high-temperature firing process in kilns, resulting in durable, solid units.

The primary raw materials include clay, shale, and fire clays. Water, engobes (clay slurries), colorants, concrete (for concrete bricks), sand (for sand-lime bricks), fly ash (for fly ash bricks), lubricants, and sawdust (as burnout material) are also essential components.

Clays are categorized into surface clays, shales, and fire clays. Each type contributes distinct properties to the bricks, and manufacturers strategically blend them to achieve specific characteristics.

Water plays a crucial role in achieving plasticity during the preparation phase. It is added to clay to facilitate the forming process, allowing the clay to be shaped or molded.

Various textures are achieved through forming methods, and coatings like engobes (clay slurries) or colorants are applied to the brick surface. Glazes, either single-fired or double-fired, can also be used to create distinctive patterns and textures.

Colorants, including iron for red hues, are naturally present in clays. The final color of the bricks is influenced by the chemical composition, firing temperatures, and kiln control methods.

Clays shrink during drying and firing, leading to size variations. Manufacturers control and mitigate these variations within specified ranges. Although absolute uniformity is challenging, factors contributing to shrinkage are carefully managed.

Durability depends on achieving incipient fusion and partial vitrification during firing. Compressive strength and absorption values, related to firing temperatures, serve as predictors of durability in brick specifications.

Brick manufacturing minimizes waste by recycling processed clay and shale. Plants are strategically located near raw material sources, reducing transportation. The industry uses waste products, such as bottom- and fly-ash, and actively seeks water conservation methods.

The Brick Industry Association’s environmental policy emphasizes innovation, environmentally friendly practices, energy efficiency, recyclability, and low maintenance. The industry commits to meeting or exceeding state and federal environmental regulations.

While the fundamentals remain constant, technological advancements have increased efficiency and product quality. The industry has embraced mechanization, adapting production methods to specific raw materials and operational needs.

The key phases include mining and storage, preparation, forming the brick (via extrusion, molding, or dry-press), drying, hacking and firing, and cooling and de-hacking. Each phase contributes to the meticulous crafting of durable and versatile bricks.

The forming method, whether extrusion, molding, or dry-press, significantly influences the texture of the brick. Molded bricks commonly exhibit sand-finished surfaces, while extruded bricks offer a diverse range of textures.