Why Karimnagar red bricks are Famous in Construction Karimnagar, with its rich history and cultural heritage, has been a hub for traditional craftsmanship and bricks. In the world of construction, the name “Karimnagar bricks in Hyderabad” echoes with the legacy of exceptional red bricks The art of brick making in this region dates back generations, with families passing down the intricate techniques and knowledge required to create bricks of exceptional quality. Unique Characteristics of Karimnagar Bricks: Clay Composition: Karimnagar bricks are known for their distinctive clay composition. The region’s soil provides a unique blend of minerals and organic matter, contributing to the durability and strength of the bricks. Natural Color Palette: Unlike standardized bricks, Karimnagar red bricks often showcase a natural and earthy color palette. The hues range from warm reds to subtle browns, adding a rustic charm to the structures built with these bricks. Craftsmanship: Skilled artisans in Karimnagar employ time-honored techniques in the brickmaking process. Each brick is carefully molded, dried, and fired to perfection, resulting in a product that reflects the dedication and expertise of the craftsmen. Applications in Construction: Structural Integrity: Karimnagar red bricks are revered for their structural integrity. Builders in Hyderabad and architects in Telangana prefer these bricks for their ability to withstand environmental elements and contribute to the longevity of structures. Architectural Aesthetics: The natural color variations and textures of Karimnagar bricks make them a favored choice for architects aiming to create visually appealing and distinctive buildings. From traditional homes to modern structures, these bricks add character to architectural designs. Preservation Efforts: As modern construction materials gain popularity, there is a growing awareness of the importance of preserving traditional crafts like Karimnagar brickmaking. Initiatives to document and promote these age-old techniques play a crucial role in ensuring the continuity of this cultural heritage. Karimnagar Red Bricks: Pricing & Sourcing Insights Pricing Dynamics: Karimnagar red brick prices exhibit a competitive range from Rs 9 to 12 INR. This affordability makes them an attractive choice for construction projects in Hyderabad of varying budgets, offering flexibility without compromising on quality. Local Sourcing: Explore nearby suppliers for Karimnagar bricks to streamline logistics and enhance accessibility. Local connections often result in cost-effective solutions, minimizing transportation expenses and supporting the local economy. Online Procurement Convenience: Embrace the convenience of online procurement through platforms like Hyderabad Builders. This digital approach simplifies the brick acquisition process, providing a seamless experience for both homeowners and builders, saving time and effort. Karimnagar bricks strength : Despite their lightweight nature, Karimnagar bricks can have impressive compressive strength. The clay used and art man ship to enhance structural integrity, making them suitable for various construction applications. Ease of Handling: The reduced weight of these bricks makes them easier to transport, handle, and install. This can contribute to faster construction times and lower labor costs Supplier Selection Criteria: When selecting Karimnagar brick suppliers, prioritize quality. Thoroughly inspect the bricks to ensure they meet the required standards. Be vigilant against low-grade alternatives, ensuring that the chosen supplier aligns with the construction standards and specific needs of your project. This ensures the longevity and structural integrity of the built environment if you like our Karimnagar bricks article please like share Why are Karimnagar red bricks famous in construction? Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo. Where can one source Karimnagar bricks locally? if your form Local Karimnagar you can source from local Brik klin logistics and enhance accessibility. but your from out side of Karimnagar brick supplier you can contact them what is the karimnagr brick supplier phone number ? you can contact +91 9392246389 for Karimnagar bricks supplier Is online procurement of Karimnagar bricks convenient? Yes, platforms like Hyderabad Builders offer the convenience of online procurement. This digital approach simplifies the brick acquisition process, saving time and effort for both homeowners and builders What is the compressive strength of Karimnagar bricks despite their lightweight nature? Despite being lightweight, Karimnagar bricks can have impressive compressive strength. The specific clay composition and craftsmanship enhance their structural integrity, making them suitable for various construction applications. How do Karimnagar bricks contribute to ease of handling in construction? The reduced weight of Karimnagar bricks makes them easier to transport, handle, and install. This contributes to faster construction times and lower labor costs, enhancing overall efficiency. What criteria should be considered when selecting Karimnagar brick suppliers? Quality should be the top priority when selecting Karimnagar brick suppliers. Thoroughly inspect the bricks to ensure they meet required standards, and be vigilant against low-grade alternatives. The chosen supplier should align with construction standards and project-specific needs to ensure longevity and structural integrity. can Karimnagar bricks are used in load bearing walls Karimnagar bricks are suitable for use in load-bearing walls. These bricks are known for their structural integrity and durability, making them a reliable choice for various construction applications, including load-bearing walls. what is the price of Karimnagar bricks> Karimnagar bricks range from Rs 9 to 12 INR, offering affordability without compromising quality. price depend on the quantity and location

No of bricks required in India Accurate estimation of bricks is pivotal in house construction in India and plays major role in construction cost . Recognizing brick types like Modular and Conventional, with dimensions such as 230mm x 110mm x 75mm, is foundational. For a standard 4″ brick wall, the thumb rule suggests 55 bricks per square meter, factoring in a 10% wastage allowance. Opting for a robust 9″ double-layer wall doubles the requirement to 110 bricks per square meter, ensuring structural integrity. This straightforward rule simplifies planning, aiding homeowners and builders in precise brick calculations for successful house construction. Types of Bricks & Brick Dimensions Type of Bricks Dimensions in mm Dimensions in inches Modular/Metric Bricks 190mm x 90mm x 90mm 7.48in x 3.54in x 3.54in Non-Modular Bricks 230mm x 110mm x 70mm 9in x 4.33in x 2.75in Conventional Bricks 230mm x 110mm x 110mm 9in x 4.33in x 4.33in English Size Bricks 230mm x 115mm x 75mm 9in x 4.5in x 3in How many Bricks Required per 1 square feet 1 sqft = 144 inch 1brick areas is 32 sq inch, so no of bricks required for 1 square feet for 4.5 inch wall is 144/32inch = 4.5 bricks no of bricks required for 1 square feet for 9inch wall is 9-10 bricks . How Many bricks required per 1 cft ? 4.5 inch Brick wall calculator number of bricks per square meter Size: 230mm x 110mm x 75mm (0.230×0.110×0.075 m)Mortar Thickness: 10 to 15mm (0.01m)By adding the thickness of the mortar Length of Bricks in mm (L) = 230mm + 10mm = 240mm – 0.240m Width of Bricks in mm (W) = 110mm + 10mm = 120mm – 0.110 Thickness of Bricks in meter (T) =75 mm + 10mm = 85mm – 0.085m Length (L): 240mm – 0.240mWidth (W): 120mm – 0.120mThickness (T): 85mm – 0.085mArea of Each Brick: 0.0204 sqmNo. of bricks in 1 square meter: 50 bricksConsider 10 % as brick wastage Number of bricks per square meter for 4.5 inch wall = 50 + 5 = 55nos/sqm 9inch Brick Wall or Double Layer No. of bricks in 1 square meter for 4.5inch wall: 55No. of bricks in 1 square meter for 9inch wall: 110 (twice the thickness of 4.5inch wall) Application of Thumb Rule Given: 4.5inch brick wall size = 3m x 3mNo. of bricks in 4.5inch wall of 9m2: 495 bricks The thumb rule simplifies brick estimation, providing a quick way to calculate the number of bricks per square meter for different wall types. List of how many bricks required for construction no of bricks (area/ volume ) Bricks per Unit Bricks required for wall 4.5 inch wall Bricks required for 9inch Wall 100 Square Feet 4.5 to 5 bricks/sq ft 450 to 500 bricks 900 to 1000 bricks 500 Square Feet 4.5 to 5 bricks/sq ft 2250 to 2500 bricks 4500 to 5000 bricks 1000 Square Feet 4.5 to 5 bricks/sq ft 4500 to 5000 bricks 9000 to 10000 bricks 10 Square Meters 55 bricks/sq m 550 bricks 1100 bricks 20 Square Meters 55 bricks/sq m 1100 bricks 2200 bricks 10 Cubic Feet 13.5 bricks/cft 135 bricks 270 bricks 20 Cubic Feet 13.5 bricks/cft 270 bricks 540 bricks 2 Cubic Meters 500 bricks/m3 1000 bricks 2000 bricks 3 Cubic Meters 500 bricks/m3 1500 bricks 3000 bricks 4 Cubic Meters 500 bricks/m3 2000 bricks 4000 bricks 5 Cubic Meters 500 bricks/m3 2500 bricks 5000 bricks is you like this article please follow us of Hyderabad builders What is the difference between a 4″ brick wall and a 9″ brick wall in terms of brick quantity? A 9″ brick wall requires twice the number of bricks compared to a 4″ wall. The thumb rule suggests 110 bricks per square meter for a 9″ wall. How many bricks are typically required for 1 square feet 4.5 to 5 bricks per square foot How many bricks in 1 square meter? 55 bricks are required for 1 square meter How many bricks required for 1 cubic feet Size of the brick = 9 inch×4.5 inch×3 inch Size of the brick with mortar = 9.08 inch×4.58 inch×3.08 inch , which is approximately 128 cubic Volume of 1 cft = 1ftx1ft x1ft = 12inx 12in x 12in = 1728 cubic inches Volume of the brick with motor= L X B X H Now, let’s convert cubic inches to cubic feet: no of bricks = Volume in 1 cft / volume of 1 brick with motor no of bricks =1728/128 Number of bricks for 1 cft = 13.5 bricks No of bricks required for 4 inch wall per square meter Total no of bricks required for 4.5 inch how many bricks in 100 square feet 9 inch wall For a square feet you will be required 4.5 to 5 bricks for a 4inch wall. For a 9 inch wall 900-1000 bricks are required to construct 100 square-feet wall

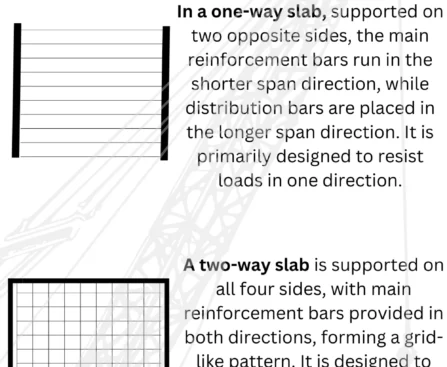

One way slab vs two way slab in construction What is a slab: In construction, a “slab” refers to a flat, horizontal structural element typically used as a floor or roof in buildings. Slabs are a fundamental component of building structures and provide a stable surface for people, furniture, and equipment. They distribute loads evenly and transfer them to the supporting beams, columns, or walls. There are various types of slabs used in construction, and the choice of a particular type depends on factors such as the structural requirements, span length, and architectural design. Types of slabs include One-Way Slab: A one-way slab is supported on two opposite sides (beams or walls). Main reinforcement bars are placed in the shorter span direction, while distribution bars are placed in the longer span direction. Suitable for smaller spans. Two-Way Slab: A two-way slab is supported on all four sides. Main reinforcement bars are provided in both directions. Suitable for larger spans and more complex structures. Flat Slab: A flat slab is a two-way reinforced concrete slab with no beams between columns. The slab is directly supported on columns, providing a simple and open interior space. Ribbed Slab: A ribbed slab incorporates a series of closely spaced ribs or beams into the concrete to improve its load-carrying capacity. This type of slab reduces the overall weight of the structure and enhances its strength. Waffle Slab: A waffle slab is a two-way concrete slab reinforced with ribs in both directions. The ribbed pattern resembles a waffle, providing a combination of strength and reduced weight. Post-Tensioned Slab: A post-tensioned slab uses high-strength tendons to apply compression to the concrete after it has been poured and cured. This method allows for thinner slabs and increased spans. Precast Slab: Precast slabs are manufactured off-site and transported to the construction site. They offer efficiency and quality control, as they are produced in a controlled environment. One-Way Slab vs. Two-Way Slab: Key Differences In structural engineering, the distinction between one-way and two-way slabs is based on the ratio of the longer span (L) to the shorter span (B), influencing the reinforcement configuration and load distribution. Here are the key differences presented in a practical context: Practical Differences: Support Configuration: One-Way Slab: Supported on two opposite sides, typically by beams or walls. Two-Way Slab: Supported on all four sides, creating a grid-like system of support. Reinforcement Placement: One-Way Slab: Main reinforcement bars (tension bars) are placed in the shorter span direction, and distribution bars (shear bars) are provided in the longer span direction. Two-Way Slab: Main reinforcement bars are placed in both directions, forming a grid pattern to distribute loads in both longitudinal and transverse directions. Load Distribution: One-Way Slab: Primarily designed to resist loads in one direction, suitable for simple and small-span structures. Two-Way Slab: Designed to resist loads in both longitudinal and transverse directions, suitable for larger spans and complex structures. Span-to-Depth Ratio: One-Way Slab: Typically has a higher span-to-depth ratio, making it suitable for longer spans. Two-Way Slab: Generally has a lower span-to-depth ratio, providing stability for loads in multiple directions. Difference between Oneway and Twoway slab Characteristic One-Way Slab Two-Way Slab Load Distribution Supported on two opposite sides Supported on all four sides Bending Resistance Resists bending in one direction Resists bending in both directions Reinforcement Placement Main bars placed in one direction Main bars placed in both directions Span Ratio Consideration Economical for L/B > 2 Suitable for L/B < 2 Grid Pattern Forms a single grid pattern Forms a grid pattern in both directions Common Usage Common in shorter span applications Common in larger span applications Load distribution of one way slab The load distribution in a one-way slab primarily occurs in the direction perpendicular to the supporting beams or walls. Since one-way slabs are designed to resist bending in only one direction (either the longer span or the shorter span), the primary load distribution is along the shorter span of the slab. In a one-way slab: Load Distribution Direction: Perpendicular to the support. Main Reinforcement (Tension Bars): Placed in the shorter span direction to resist tensile forces. Distribution Bars (Shear Bars): Provided in the longer span direction to enhance shear strength. The load is transferred to the supporting elements, typically beams or walls, along the shorter span. This design is suitable for simpler structures with smaller spans where the load distribution in one direction is sufficient to meet the structural requirem Factors Influencing Choice Between One-way and Two-way Slabs: Span Length: One-way slabs are suitable for smaller spans, while two-way slabs are preferred for larger spans. Structural Requirements: The load distribution and structural demands influence the choice between one-way and two-way slabs. Architectural Design: The desired aesthetic and layout may impact the selection based on the support configuration. href=”https://in.pinterest.com/pin/1018376534476416631/”>are you pin What is one way two way slab ratio? One-way slab: It typically has a longer span in one direction and a shorter span in the perpendicular direction. The one way slab aspect ratio is greater than 2. Two-way slab: It has relatively equal spans in two perpendicular directions. The two way slab aspect ratio is generally less than 2. Difference between oneway and twoway slab Support Side Bending Resistance Span Ratio One-way Slab 2 sides One direction L/B > 2 Two-way Slab 4 sides Both directions L/B < 2 What is one way slab and two way slab in construction? One-way and two-way slabs refer to different structural systems used in building construction, particularly in reinforced concrete structures. The main difference between them lies in the way they distribute loads and resist bending moments. How do different slab types impact project costs and construction timelines? Specialized slabs may have additional costs, but long-term benefits could offset initial expenses. Precast slabs can accelerate construction, while complex designs may extend timelines. Can a building incorporate both one-way and two-way slabs? Yes, buildings with varying spans or irregular layouts may benefit from a combination for efficiency and optimisation.

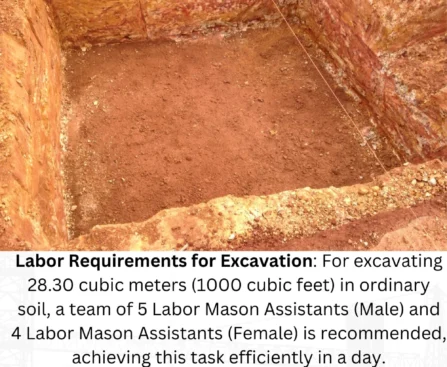

What is Earth Work? Earthwork in construction refers to the process of manipulating the earth’s surface, involving excavation, grading, and backfilling to create a desired topography for building projects. It encompasses activities such as digging, moving, and compacting soil to prepare the ground for foundations, roads, embankments, and other structures. Earthwork plays a fundamental role in shaping the landscape and ensuring a stable foundation for various types of construction projects. The efficient allocation of manpower is essential to ensure that these tasks are completed within the stipulated time and budget. In this article, we will discuss the specific manpower requirements for earthwork, focusing on excavation and refilling processes. labor Required for Earth work excavation and refilling Manpower Requirements for Excavation: Excavation in Foundations and Trenches: Type of Soil: Ordinary soil Quantity: 28.30 cubic meters (1000 cubic feet) Distance of Disposal: Up to 30 meters (100 feet) Lift: 1.5 meters (5 feet) Manpower: 5 Labor Mason Assistants (Male) and 4 Labor Mason Assistants (Female) Daily Output: 28.30 cubic meters (1000 cubic feet) Explanation: The excavation process involves digging into ordinary soil in foundations and trenches. A team comprising 5 Labor Mason Assistants (Male) and 4 Labor Mason Assistants (Female) is capable of excavating 28.30 cubic meters (1000 cubic feet) per day. This includes the necessary disposal of excavated material within a 30-meter distance and a lift of 1.5 meters. Manpower Requirements for Refilling: Refilling Excavated Earth in Foundations and Plinth: Layers: Consolidation in 15cm (6″) layers Quantity: 28.30 cubic meters (1000 cubic feet) Manpower: 3 Labor Mason Assistants (Male) and 2 Labor Mason Assistants (Female) Daily Output: 28.30 cubic meters (1000 cubic feet) Explanation: The refilling process involves consolidating the excavated earth in foundations and plinth in layers of 15cm (6″). A team comprising 3 Labor Mason Assistants (Male) and 2 Labor Mason Assistants (Female) can efficiently complete the refilling of 28.30 cubic meters (1000 cubic feet) per day People also read: labor cost in India, construction cost cost in India, building materials cost in 2024 you can also share our pin What is earthwork in construction? Earthwork in construction involves activities such as excavation, grading, and backfilling to shape the ground for building projects. It’s crucial for creating a stable foundation and desired topography. Why is efficient manpower allocation essential for earthwork? Efficient manpower allocation ensures timely completion and cost-effectiveness in construction projects. It optimizes resources for tasks like excavation and refilling. What are the specific manpower requirements for excavation in ordinary soil? For excavation in ordinary soil, a team of 5 Labor Mason Assistants (Male) and 4 Labor Mason Assistants (Female) can efficiently handle 28.30 cubic meters (1000 cubic feet) per day. How is the refilling process carried out in earthwork? The refilling process involves consolidating excavated earth in foundations and plinth using 3 Labor Mason Assistants (Male) and 2 Labor Mason Assistants (Female) in 15cm (6″) layers. Can the provided manpower estimates vary for different projects? Yes, the manpower estimates are general guidelines. Site-specific conditions, soil types, and project variables may influence actual workforce needs. Are there any safety considerations mentioned in the article? The article doesn’t explicitly mention safety considerations. Users are advised to adhere to safety regulations and consult professionals for a comprehensive understanding of safety measures. Is this information applicable to all construction projects globally? The information provides a general framework. However, local regulations, environmental conditions, and project specifics may necessitate adjustments in manpower planning. What is the daily output for both excavation and refilling processes? For both excavation and refilling, the daily output is specified as 28.30 cubic meters (1000 cubic feet) per day.

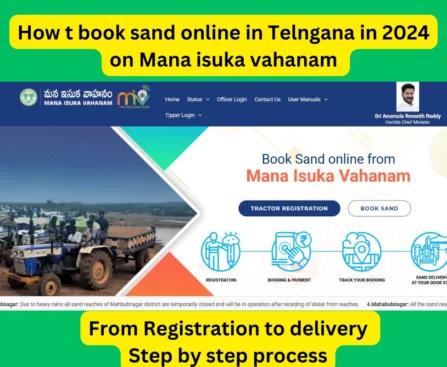

Quick summary on how to book sand online in Telangana “Telangana government made seamless sand booking for home owners small builders and developers in Telangana with Mana Isuka Vahanam’s user-friendly platform at [https://tsmiv.cgg.gov.in] for their construction purpose as sand id the main building materials in construction Telangana government wan sand process to be more transparency in Sand trade and usage . How to book sand online in Telangana in simple words visit website https://tsmiv.cgg.gov.in click on new registration After a swift registration, log in using your mobile number and PIN. Navigate to the sand booking section, provide essential details, and accept terms. Initiate the booking, choose a payment method, and complete the transaction. Expect a prompt confirmation with a unique ID sent to your registered mobile number. For your records, print or save the confirmation. Simplify construction projects in Hyderabad, Telangana by embracing the convenience of online sand booking, eliminating traditional hassles and ensuring a quick, efficient process. How to book sand online in Telangana in 2024 Visit the Website: Step 1: Open your web browser and go to the website: Mana isuka vahanam https://tsmiv.cgg.gov.in. Step 2: Look for an option like “Book Sand for New Sand Bookings” on the website’s homepage. Account Registration: Step 3: Click on the “Register Here” link for new customer registration. Login: Step 4: Enter your mobile number and click on “Send OTP” to receive a One-Time Password . Step 5: Enter the OTP received on your mobile and click on “Validate.” Step 6: Create a 4-digit PIN number and complete the registration process. Step 7: Once registered, go back to the home page and log in using your mobile number and the PIN you just created. Step 8: Navigate to the “Book Sand” section on the website. Step 9: Fill in the required details, including customer details, sand delivery address, and sand details (e.g., Address, Landmark, District, Mandal, Village, Pin Code). Step 10: Select sand details such as sand reach, quantity, usage type, and the date of delivery. Step 11: Check the Terms & Conditions box. Step 12: Click on “Book Sand.” This action will likely direct you to the payment gateway. Step 13: Choose your preferred payment method (Internet Banking, Credit Card, Debit Card, UPI). Step 14: Complete the payment process. Step 15: After successful payment, the system should display transaction details, and you should receive a Booking ID to your registered mobile number. Disclaimer: The information provided in this [document/article/content] is based on publicly available knowledge . While efforts have been made to ensure accuracy, it is recommended to verify details from official sources or relevant authorities. The author or publisher does not claim ownership of the information but aims to present it in a comprehensible manner. Any reliance you place on such information is strictly at your own risk.