What is Marine plywood Plywood marine is the plywood variant which is resistant to moisture and is therefore used for outdoor applications or in humid areas. The sheet is, as with plywood birch, bonded with a waterproof glue. Marine is more resistant to moisture, which makes this variant suitable for outdoor applications. But of course you can also choose the sheet because of its beautiful pink-red colour with coarse flames and the fact that it is easy to work with. Plywood is made up of various veneer layers. These layers are glued crosswise on top of each other. This results in a stable sheet. The sheets have an attractive edge that can be used for visual applications. Marine plywood applications Boat Building: Marine plywood finds its primary application in constructing boats and ships, where its water-resistant properties are crucial for boat hulls, decks, bulkheads, and other structural components. Marine and Nautical Structures: Used in the construction and repair of marine structures like piers, docks, jetties, and marinas due to its ability to resist decay and delamination. Outdoor Furniture: Suitable for crafting durable outdoor furniture such as picnic tables, garden benches, and chairs, thanks to its resistance to moisture and weathering. Garden and Landscaping: Ideal for landscaping applications like garden beds, retaining walls, and decorative structures exposed to soil and moisture. Exterior Cladding: In some regions, marine plywood serves as an exterior cladding material for buildings, providing protection in areas with high humidity or heavy rainfall. Decks and Patios: Used for deck surfaces, patios, and outdoor walkways to ensure resilience against moisture and the elements. Bathroom and Kitchen Cabinets: Occasionally employed for cabinets and cupboards in bathrooms and kitchens, particularly where water resistance is a priority. Transportation: Found in transportation applications, especially in trailers and vehicles designed for carrying goods or equipment, ensuring a load-bearing surface that can withstand exposure to the elements. Industrial Applications: Utilized in certain industrial settings like warehouses and storage facilities where high humidity or water exposure is common. Stage and Scenery Construction: Employed in the construction of outdoor stages and temporary event scenery, providing durability and weather resistance. Water Resistance: Marine plywood is highly resistant to water and moisture, making it suitable for applications where the wood will be exposed to water or humidity. It can withstand prolonged exposure to water without delaminating, warping, or rotting. Quality Construction: Marine plywood is typically constructed with several layers of high-quality, durable veneers, and it uses water-resistant adhesives in its manufacturing process. This construction ensures its strength and durability. No Core Gaps: One distinctive feature of marine plywood is that it is manufactured without any gaps or voids in its core layers, enhancing its water resistance. Marine and Nautical Applications: Marine plywood is widely used in boat building and repair. It is used for boat hulls, decks, and other structural elements due to its ability to withstand the challenging conditions of marine environments. Exterior and Outdoor Use: Beyond marine use, marine plywood is also suitable for various outdoor applications, including outdoor furniture, garden structures, and exterior sheathing for buildings. Higher Cost: Marine plywood is typically more expensive than standard plywood due to its superior quality and water-resistant properties. A-A Grade Quality: Highest quality. Material: Top-quality hardwood veneers with uniform color and grain pattern. Defects: No defects, knots, or voids. Waterproof: Yes, treated with waterproof adhesive using cross-banding. Best For: Boat interiors, cabinets, and furniture. Attributes: Superior water resistance, durability, stability, and appearance. Consideration: Comes with a higher price tag. A-B Grade Quality: High-quality marine plywood. Material: Hardwood veneers with uniform color and grain pattern, minor defects allowed. Waterproof: Yes, treated with waterproof adhesive using cross-banding. Appearance: Slight color variations and minor defects. Attributes: Superior water resistance, durability, and stability. Best For: Numerous marine and outdoor applications. B-B Grade Quality: Lower-quality marine plywood. Material: Hardwood veneers with knots, patches, and other defects but structurally sound. Waterproof: Yes, treated with waterproof adhesive using cross-banding. Attributes: Good water resistance, durability, and stability. Best For: Subflooring, decking, and structural applications where appearance is secondary. Medium-density Overlay (MDO) Special Feature: Resin-impregnated fiber layer on both sides for weatherproofing. Material: Fiber layer between two layers of hardwood veneers, bonded with waterproof adhesive using cross-banding. Surface Finish: Uniform surface finish suitable for painting or staining. Attributes: Improved water resistance, durability, and stability. Best For: Marine and outdoor applications. High-density Overlay (HDO) Special Feature: Higher resin percentage for a shinier and harder surface. Attributes: Improved water resistance, durability, and stability compared to MDO. Best For: Applications requiring a uniform surface finish and superior water resistance, like boat exteriors and outdoor structures. Which is best Marine plywood best grade of marine plywood depends on your project. A-A is ideal for a polished appearance in boat interiors and furniture. A-B suits versatile marine uses, B-B for structural strength, MDO for outdoor painting, and HDO for superior water resistance in boat exteriors and outdoor structures. Feel free to reach out for guidance. Marine plywood size guide Marine plywood is available in a range of thickness options, providing flexibility for various applications. The standard sheet size for marine plywood is 2400 x 1200mm Thickness Options Standard Sheet Size 4.5mm 2400 x 1200mm 6mm 2400 x 1200mm 9.5mm 2400 x 1200mm 12.5mm 2400 x 1200mm 16mm 2400 x 1200mm 19mm 2400 x 1200mm 15mm 2400 x 1200mm Top Plywood companies In India Century Plyboards: Plywood Grades: MR, BWR, FR.Products: Sainik MR, Sainik 710, Bond 710, Club Prime, Architect Ply.Other Products: Laminate, Veneer, HDF, MDF, Particle board, WPC boards, Doors, Fibre cement boards. Greenply Industries: Plywood Grades: BWP, MR, Others.Products: Platinum, Club Plus 700, Club 500, 710 Plywood, Gold Platinum, Gold, Optima-G, Eco-tech 710, Eco-tech MR, Jansathi, Blockboards.Other Products: Laminates, Veneers, Flush Doors, WPC doors, PVC doors. Solid Ply: Products: Marine Grade Plywood (710), MR Grade Plywood (303), Block Board, Flexi Ply, Film-Faced Shuttering Plywood, Premium Flush Doors. Duroply: Plywood Varieties: Titanium, Derby, Pumaply, Marine, Macplatinum (710), Techply (European rotary veneer finish IS 710), Fireshield (FR grade IS

The Unstable Ground Dilemma: Why Foundations Matter Understanding the importance of addressing foundation challenges in construction is crucial. Here’s a closer look at why building on unstable ground is such a critical issue: Geological Diversity: Earth’s geological makeup varies dramatically from one location to another. What’s solid ground in one place may be unstable elsewhere. This diversity necessitates a deep understanding of local geology for safe construction. Earthquake Hazards: Regions prone to seismic activity, such as the Pacific Ring of Fire, pose a unique challenge. Structures must be designed not only to withstand the forces of earthquakes but also to provide safety for occupants. Settlement and Subsidence: Soft or compressible soils can lead to settlement and subsidence, causing structural damage over time. Mitigating these effects is crucial to the longevity of buildings. Environmental Considerations: In some areas, construction on unstable ground can have environmental implications, such as the risk of landslides or soil contamination. Balancing construction needs with environmental preservation is a delicate task. In the sections that follow, we’ll dive deep into how construction professionals confront these challenges head-on. We’ll explore engineering solutions, innovative technologies, and real-world case studies that illustrate the remarkable feats achieved when building on unstable ground. Geotechnical Engineering: The Foundation of Success One of the keys to conquering foundation challenges lies in geotechnical engineering. Here’s a glimpse into its significance: Site Investigation: Comprehensive site investigations are conducted to understand the soil and geological conditions thoroughly. This data informs the design and construction process. Foundation Design: Engineers develop specialized foundation designs tailored to the specific challenges of the site, whether it involves deep piles, mat foundations, or other innovative solutions. Seismic Design: In earthquake-prone regions, buildings are equipped with seismic-resistant features like base isolators and damping systems, ensuring safety during seismic events. Innovative Solutions: Pushing the Boundaries Building on unstable ground demands innovation. Here are a few innovative solutions: Micropiles and Soil Grouting: These techniques stabilize weak soils and provide foundation support in challenging conditions. Seismic Retrofitting: Existing structures in earthquake-prone areas are often retrofitted to meet modern safety standards. Floating Foundations: In areas with high water tables, floating foundations are employed to counter buoyancy forces and provide stability. Case Studies: Triumph Over Geological Adversity Real-world examples demonstrate the triumph of engineering ingenuity over geological adversity. We’ll explore projects that have successfully tackled foundation challenges, from skyscrapers in earthquake-prone regions to bridges on unstable soils. The Future of Foundation Engineering: Innovations on the Horizon As technology and understanding of geotechnical engineering continue to advance, we’ll take a glimpse into the future of foundation construction, including promising innovations like self-healing materials and advanced monitoring systems. By the end of this blog post, you’ll gain a deeper appreciation for the complexities and achievements involved in building on unstable ground. It’s a testament to human ingenuity and the pursuit of safe and resilient construction practices even in the most challenging environments.

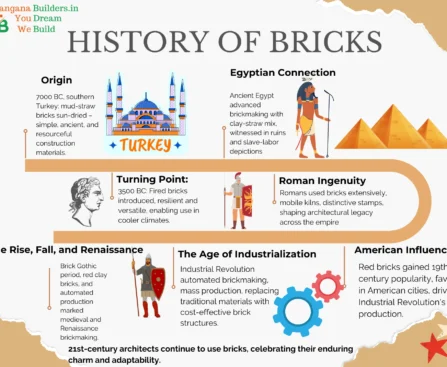

Have you ever stopped to think about the unassuming brick? These small, rectangular building blocks have been an integral part of human history for millennia, playing a crucial role in the development of our civilizations and architectural wonders. From their humble beginnings as sun-dried mud bricks to the modern architectural marvels constructed with cutting-edge brick technology, the story of bricks is one of intrigue, innovation, and endurance. The Origins and History of Bricks The history of bricks dates back to a time long before the modern conveniences we take for granted today. In approximately 7000 BC, in what is now southern Turkey, the earliest bricks were crafted from mud and straw, left out to harden in the sun. These ancient mud bricks, also known as adobe bricks, were simple yet effective, showcasing the resourcefulness of our ancestors. The Egyptian Connection in the history of bricks: Ancient Egypt played a significant role in the evolution of brickmaking. Clay mixed with straw became the new building materials , and evidence of this ancient practice can still be seen today in the ruins of Harappa, Buhen, and Mohenjo-daro. Paintings in Thebes depicted the hard work that went into crafting sun-dried bricks, with slaves mixing and carrying the clay, offering us a glimpse into the ancient world. The Turning Point: Fired Bricks: Around 3500 BC, a game-changing innovation occurred with the invention of fired bricks. This advancement allowed bricks to be produced without relying on the sun’s heat, making them suitable for use in cooler climates. The fired bricks were stronger, more resilient, and opened up a world of architectural possibilities. How have the Romans been of the history of bricks and there ingenuity? The Romans left an indelible mark on the use of bricks. They introduced mobile kilns and stamped their bricks with the mark of the overseeing legion. These bricks varied in size and shape, giving their structures a distinctive look. The Romans used bricks extensively, from walls and forts to cultural centers and aqueducts. Their architectural legacy endures in iconic structures like the Herculaneum Gate of Pompeii and the Baths of Caracalla in Rome. The Rise, Fall, and Renaissance: As the Roman Empire declined, so did the widespread use of bricks. The art of brickmaking continued primarily in Italy and the Byzantine Empire. It wasn’t until the 11th century that brickmaking spread to France, followed by northern Germany. The Brick Gothic period, known for its distinctive red clay bricks, emerged as an architectural style that used split courses of bricks in varying colors. The Age of Industrialization: The Industrial Revolution revolutionized brickmaking, with machines introduced to automate the process. The production capacity increased significantly, and brick structures became more accessible and affordable, replacing traditional building materials like stone. Red Bricks and the American Influence to the history of bricks: Red bricks gained popularity during the 19th century, with American cities like Boston and New York favoring locally made bricks. The Industrial Revolution’s influence led to the mass production of bricks, making them the preferred building material. A Contemporary Renaissance: In the mid-18th century, brick walls regained their popularity after being concealed with plaster for a time. Today, brick structures are still commonly used, cherished for their timeless appeal and versatility. A Legacy of Bricks: The legacy of brick endures in the 21st century, with architects like Le Corbusier, Frank Lloyd Wright, and Louis Kahn incorporating bricks into their iconic designs. The enduring charm and adaptability of bricks continue to shape the world’s architectural landscape. From sun-dried mud bricks to modern marvels, the history of bricks is a testament to human ingenuity and adaptability. These small blocks have left an indelible mark on our world, and their intriguing story continues to be written in the buildings that surround us. Some of the Brick Facts Manual Brick Making in Medieval Times: Bricks were initially made by hand, with workers kneading clay and placing it in wooden molds. The excess clay was wiped off, and the brick-shaped clay was removed from the frame. Handmade Bricks Until 1885: Handmade brick production persisted until the late 19th century, with workers individually crafting bricks. The Industrial Revolution’s Impact: The industrial revolution marked a significant turning point, transforming brick manufacturing. This era saw the introduction of machines, boosting production capacity and reducing manufacturing and construction costs. 1920s: Rise of Brick Making Machines: By the 1920s, brick making machines had advanced to the point where they could produce up to 12,000 bricks a day. This automation dramatically increased efficiency. Early Brick Buildings in America: Brick buildings in America date back to at least 1611, reflecting a long history of using bricks in construction. 19th Century Building Boom in America: The 19th century witnessed a building boom in America, contributing to the construction of many structures using bricks. This period of growth has continued, shaping the architectural landscape of the country. Bricks in Early American Skyscrapers: Notably, early American skyscrapers in New York, including the iconic Empire State Building, were constructed using bricks. The Empire State Building alone used a substantial quantity of bricks—10 million. What Lies Ahead from history of bricks to future of bricks ? This is particularly evident with increased industrialization and urbanization. The emergence of alternative construction techniques stems from the growing use of cement-based materials as substitutes for traditional building materials. Bricks, once costly and structurally weak, fell out of favor for skyscrapers due to their enormous sizes. Since the 1960s, bricks have been primarily utilized in the construction of affordable housing units, contributing to their decline. This decline is partly attributed to the reduced role of bricks as structural elements. In contemporary structures, brickwork is commonly reserved for aesthetic purposes, as the main frames are typically constructed using wood or metal. Nevertheless, bricks have made a resurgence as an aesthetic material in the construction of modern low and medium-rise office blocks. However, these buildings do not necessarily adhere to traditional bricklaying techniques, signaling a return to ‘brick-built’ exteriors. If a brief journey through brick

Renovating your bathroom can be an exciting project, but it’s essential to budget wisely to ensure you stay on track financially. Here’s a step-by-step guide on how to budget effectively for your bathroom renovation: 1. Assess the Area: 2. Tile and Flooring Costs: 3. Sanitaryware Selection:

Building Your Dream Home in Hyderabad: Navigating the Real Estate Landscape The Growing Real Estate Landscape in Hyderabad: Hyderabad’s real estate market has been on an upward trajectory, attracting investors and homeowners alike. The city’s strategic location, IT hubs, and thriving job opportunities have made it a preferred destination for homebuyers. With this surge in demand, builders in Hyderabad are continually innovating and expanding their services to meet the evolving needs of the market. Selecting the Right Builder: Key Factors to Consider Choosing the right builder is a pivotal decision in your home-building journey. To make an informed choice, here are some key factors to consider: 1. Experience Look for builders with a proven track record and extensive experience in the industry. 2. Reputation Reputation is everything. Research online reviews, testimonials, and ask for references. 3. Certifications Ensure that the builder holds the necessary licenses and certifications. 4. Past Projects Explore their portfolio and visit completed projects to assess quality. 5. Transparency Choose a builder who is transparent about costs, timelines, and procedures. Top Builders in Hyderabad: To help you kickstart your search, here are some of the top builders in Hyderabad: Modi Builders: Known for their commitment to quality and timely delivery, Modi Builders have a stellar reputation. Lodha: Lodha Developers specialize in luxury and eco-friendly projects, emphasizing sustainability. Aparna Constructions: With a diverse portfolio, Aparna Constructions caters to a wide range of budgets and preferences. Feel free to explore their websites and contact them directly for more information on their services. Budget and Cost Considerations: Before diving into your project, establish a clear budget. Hyderabad’s real estate market offers options for various budgets, and it’s crucial to have a financial plan in place. Discuss your budget with potential builders to ensure that your project aligns with your financial goals. The Importance of Legal Compliance: Every construction project involves legal considerations. Builders in Hyderabad must adhere to local building codes and regulations. Ensure that your chosen builder is well-versed in legal compliance and obtains the necessary permits and licenses. Sustainable and Eco-Friendly Building Practices: Hyderabad is witnessing a growing interest in sustainable and eco-friendly construction practices. Many builders are incorporating green building techniques, such as energy-efficient designs and eco-friendly materials. Consider builders who prioritize sustainability if you’re environmentally conscious. Customer Testimonials and Reviews: One of the best ways to assess a builder’s credibility is by reading customer testimonials and reviews. Hearing from previous clients about their experiences can provide valuable insights into a builder’s reliability, professionalism, and project outcomes. Questions to Ask Your Builder: When meeting with potential builders, don’t hesitate to ask questions. Here are some important ones to consider: How do you handle project delays or unforeseen issues? What warranties do you offer on your work? Can you provide a detailed cost estimate? Do you have a dedicated project manager or point of contact? The Future of Home Building in Hyderabad: As Hyderabad’s real estate landscape continues to evolve, we can expect to see innovative trends in home construction and design. From smart homes to eco-friendly architecture, the future holds exciting possibilities for homeowners. In conclusion, building your dream home in Hyderabad is an achievable goal with the right builder by your side. The city’s real estate market offers a wealth of opportunities, and the builders mentioned here are just a starting point for your journey. Remember to conduct thorough research, assess your budget, and prioritize sustainability when making your choice. Your dream home awaits! If you have any questions or need further assistance with your home-building project, feel free to contact us at Telangana Builders. We’re here to help you turn your vision into a reality. Disclaimer: The information provided in this blog post is for informational purposes only. While we have made every effort to ensure the accuracy and reliability of the information presented, it should not be construed as legal, financial, or professional advice. Building or renovating a home involves various factors, and individual circumstances may vary. We recommend conducting thorough research and consulting with qualified professionals, including architects, builders, and legal experts, to make informed decisions for your specific project. Hyderabad Builders disclaims any liability for actions taken based on the information provided in this blog post. Explore the real estate landscape in Hyderabad and find the best builders in Hyderabad, including top 10 developers and small builders in Hyderabad. Looking for prime plots? Discover the best plot developers in Hyderabad. You can even access Hyderabad builders’ contact numbers for direct inquiries. If you have specific preferences, consider exploring contactors builders in Hyderabad. Plus, get insights on the best investments in Hyderabad and the top areas to buy a flat in the city. Your real estate journey begins here.