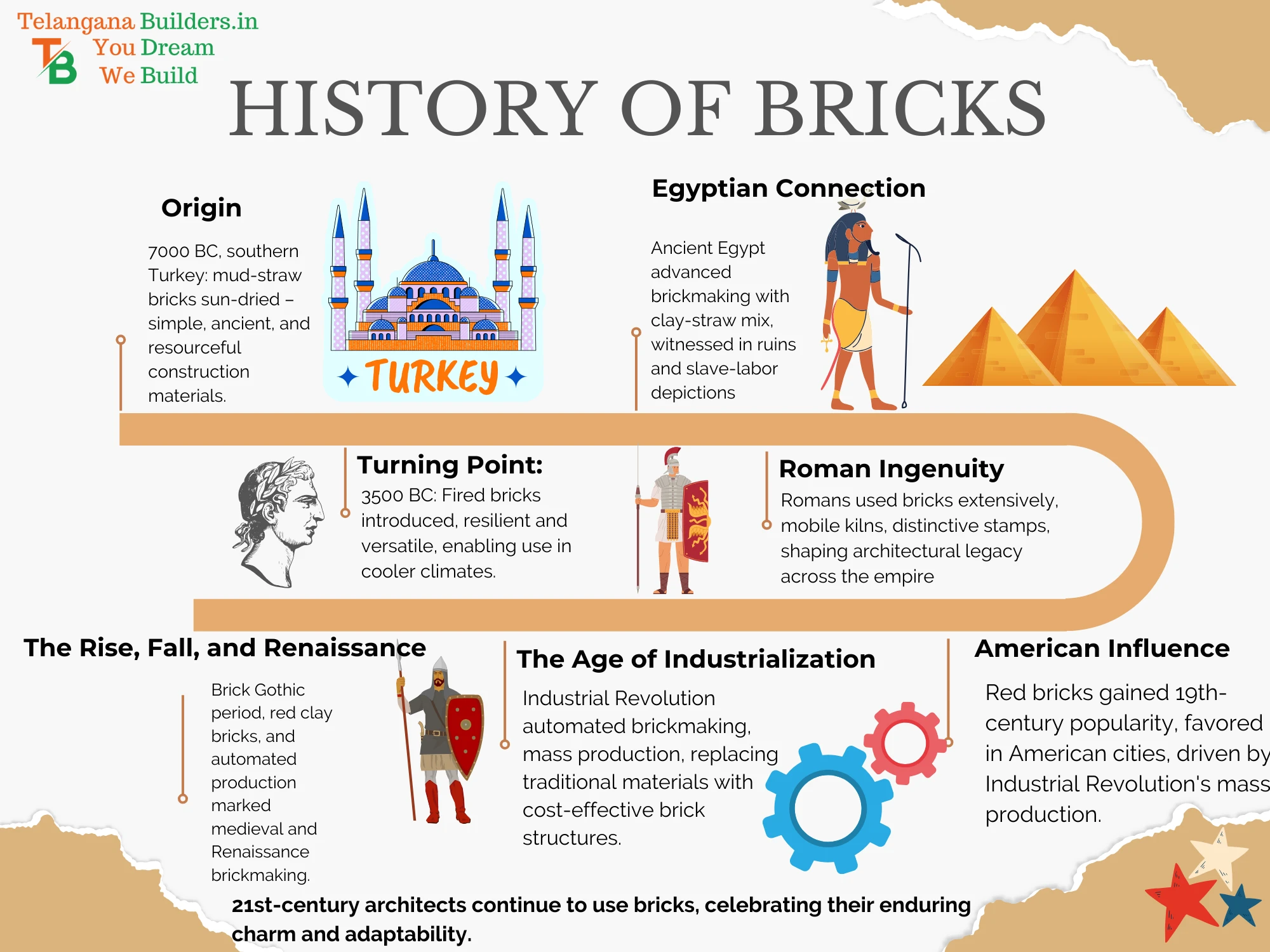

Have you ever stopped to think about the unassuming brick? These small, rectangular building blocks have been an integral part of human history for millennia, playing a crucial role in the development of our civilizations and architectural wonders. From their humble beginnings as sun-dried mud bricks to the modern architectural marvels constructed with cutting-edge brick technology, the story of bricks is one of intrigue, innovation, and endurance. The Origins and History of Bricks

The history of bricks dates back to a time long before the modern conveniences we take for granted today. In approximately 7000 BC, in what is now southern Turkey, the earliest bricks were crafted from mud and straw, left out to harden in the sun. These ancient mud bricks, also known as adobe bricks, were simple yet effective, showcasing the resourcefulness of our ancestors.

The Egyptian Connection in the history of bricks:

Table of Contents

ToggleAncient Egypt played a significant role in the evolution of brickmaking. Clay mixed with straw became the new building materials , and evidence of this ancient practice can still be seen today in the ruins of Harappa, Buhen, and Mohenjo-daro. Paintings in Thebes depicted the hard work that went into crafting sun-dried bricks, with slaves mixing and carrying the clay, offering us a glimpse into the ancient world.

The Turning Point: Fired Bricks:

Around 3500 BC, a game-changing innovation occurred with the invention of fired bricks. This advancement allowed bricks to be produced without relying on the sun’s heat, making them suitable for use in cooler climates. The fired bricks were stronger, more resilient, and opened up a world of architectural possibilities.

How have the Romans been of the history of bricks and there ingenuity?

The Romans left an indelible mark on the use of bricks. They introduced mobile kilns and stamped their bricks with the mark of the overseeing legion. These bricks varied in size and shape, giving their structures a distinctive look. The Romans used bricks extensively, from walls and forts to cultural centers and aqueducts. Their architectural legacy endures in iconic structures like the Herculaneum Gate of Pompeii and the Baths of Caracalla in Rome.

The Rise, Fall, and Renaissance:

As the Roman Empire declined, so did the widespread use of bricks. The art of brickmaking continued primarily in Italy and the Byzantine Empire. It wasn’t until the 11th century that brickmaking spread to France, followed by northern Germany. The Brick Gothic period, known for its distinctive red clay bricks, emerged as an architectural style that used split courses of bricks in varying colors.

The Age of Industrialization:

The Industrial Revolution revolutionized brickmaking, with machines introduced to automate the process. The production capacity increased significantly, and brick structures became more accessible and affordable, replacing traditional building materials like stone.

Red Bricks and the American Influence to the history of bricks:

Red bricks gained popularity during the 19th century, with American cities like Boston and New York favoring locally made bricks. The Industrial Revolution’s influence led to the mass production of bricks, making them the preferred building material.

A Contemporary Renaissance:

In the mid-18th century, brick walls regained their popularity after being concealed with plaster for a time. Today, brick structures are still commonly used, cherished for their timeless appeal and versatility.

A Legacy of Bricks:

The legacy of brick endures in the 21st century, with architects like Le Corbusier, Frank Lloyd Wright, and Louis Kahn incorporating bricks into their iconic designs. The enduring charm and adaptability of bricks continue to shape the world’s architectural landscape.

From sun-dried mud bricks to modern marvels, the history of bricks is a testament to human ingenuity and adaptability. These small blocks have left an indelible mark on our world, and their intriguing story continues to be written in the buildings that surround us.

Some of the Brick Facts

Manual Brick Making in Medieval Times:

Bricks were initially made by hand, with workers kneading clay and placing it in wooden molds. The excess clay was wiped off, and the brick-shaped clay was removed from the frame.

Handmade Bricks Until 1885:

Handmade brick production persisted until the late 19th century, with workers individually crafting bricks.

The Industrial Revolution’s Impact:

The industrial revolution marked a significant turning point, transforming brick manufacturing. This era saw the introduction of machines, boosting production capacity and reducing manufacturing and construction costs.

1920s: Rise of Brick Making Machines:

By the 1920s, brick making machines had advanced to the point where they could produce up to 12,000 bricks a day. This automation dramatically increased efficiency.

Early Brick Buildings in America:

Brick buildings in America date back to at least 1611, reflecting a long history of using bricks in construction.

19th Century Building Boom in America:

The 19th century witnessed a building boom in America, contributing to the construction of many structures using bricks. This period of growth has continued, shaping the architectural landscape of the country.

Bricks in Early American Skyscrapers:

Notably, early American skyscrapers in New York, including the iconic Empire State Building, were constructed using bricks. The Empire State Building alone used a substantial quantity of bricks—10 million.

What Lies Ahead from history of bricks to future of bricks ?

This is particularly evident with increased industrialization and urbanization. The emergence of alternative construction techniques stems from the growing use of cement-based materials as substitutes for traditional building materials.

Bricks, once costly and structurally weak, fell out of favor for skyscrapers due to their enormous sizes. Since the 1960s, bricks have been primarily utilized in the construction of affordable housing units, contributing to their decline.

This decline is partly attributed to the reduced role of bricks as structural elements. In contemporary structures, brickwork is commonly reserved for aesthetic purposes, as the main frames are typically constructed using wood or metal.

Nevertheless, bricks have made a resurgence as an aesthetic material in the construction of modern low and medium-rise office blocks. However, these buildings do not necessarily adhere to traditional bricklaying techniques, signaling a return to ‘brick-built’ exteriors.

If a brief journey through brick history has ignited a desire for something more made of the same material, feel free to explore our rich collection of bricks on our website: Brick Designer’s Collection.

Manufacturing Methods:

-

Extruded Bricks:

Made by being forced through an opening in a steel die. Results in a very consistent size and shape.

-

Wire-cut Bricks:

Cut to size after extrusion with a tensioned wire. May leave distinctive drag marks.

-

Moulded Bricks:

Shaped in moulds rather than being extruded.

-

Machine-moulded Bricks:

Clay is forced into moulds using pressure.

-

Handmade Bricks:

Clay is manually forced into moulds by a person.

-

Dry-pressed Bricks:

Similar to the soft mud method but starts with a much thicker clay mix. Compressed with great force.

Categorized by Use:

-

Common or Building Bricks:

Not intended to be visible, used for internal structure.

-

Face Bricks:

Used on exterior surfaces to present a clean appearance.

-

Hollow Bricks:

Not solid, holes are less than 25% of the brick volume.

-

Perforated Bricks:

Holes greater than 25% of the brick volume.

-

Keyed Bricks:

Have indentations in at least one face and end. Used with rendering and plastering.

-

Paving Bricks:

Intended to be in ground contact as a walkway or roadway.

-

Thin Bricks:

Have normal height and length but thin width. Used as a veneer.

Specialized Use Bricks:

-

Chemically Resistant Bricks:

Made with resistance to chemical reactions.

-

Acid Bricks:

Acid-resistant bricks.

-

Engineering Bricks:

Type of hard, dense brick used where strength, low water porosity, or acid resistance are needed. Further classified as type A and type B based on compressive strength.

-

Accrington Bricks:

A type of engineering brick from England.

-

Fire or Refractory Bricks:

Highly heat-resistant.

-

Clinker Bricks:

Vitrified bricks.

-

Ceramic Glazed Bricks:

Fire bricks with decorative glazing.

Bricks Named for Place of Origin:

-

Chicago Common Brick:

A soft brick made near Chicago, Illinois. Comes in colors like buff yellow, salmon pink, or deep red.

-

Cream City Brick:

A light yellow brick made in Milwaukee, Wisconsin.

-

Dutch Brick:

A hard light-colored brick originally from the Netherlands.

-

Fareham Red Brick:

A type of construction brick.

-

London Stock Brick:

Type of handmade brick used in London and South East England.

-

Nanak Shahi Bricks:

A type of decorative brick in India.

-

Roman Brick:

A long, flat brick typically used by the Romans.

Refrerences: wiki

Buy Bricks online

Bricks were initially made by hand in Medieval Times, with workers kneading clay and using wooden molds. This manual process continued until the late 19th century

Handmade brick production persisted until 1885, with workers individually crafting bricks.

The Industrial Revolution marked a significant turning point by introducing machines, transforming brick manufacturing, increasing production capacity, and reducing costs.

By the 1920s, brick making machines could produce up to 12,000 bricks a day, signifying a substantial increase in efficiency.

Brick buildings in America date back to at least 1611, and the 19th century witnessed a building boom, shaping the architectural landscape of the country.

Early American skyscrapers, including the iconic Empire State Building in New York, were constructed using bricks. The Empire State Building alone used 10 million bricks.

Bricks fell out of favor for skyscrapers due to their enormous sizes and structural limitations. Since the 1960s, they have been primarily used in affordable housing units.

Bricks have made a resurgence as an aesthetic material in the construction of modern low and medium-rise office blocks. They are commonly used for aesthetic purposes, while the main frames are constructed using wood or metal.

In contemporary structures, traditional bricklaying techniques are not always adhered to. Bricks are used for aesthetic purposes, signaling a return to ‘brick-built’ exteriors.

If you’re interested in exploring a diverse collection of bricks, you can visit our website: Brick Designer’s Collection.