One way slab vs two way slab in construction

Table of Contents

ToggleWhat is a slab: In construction, a “slab” refers to a flat, horizontal structural element typically used as a floor or roof in buildings. Slabs are a fundamental component of building structures and provide a stable surface for people, furniture, and equipment. They distribute loads evenly and transfer them to the supporting beams, columns, or walls.

There are various types of slabs used in construction, and the choice of a particular type depends on factors such as the structural requirements, span length, and architectural design.

Types of slabs include

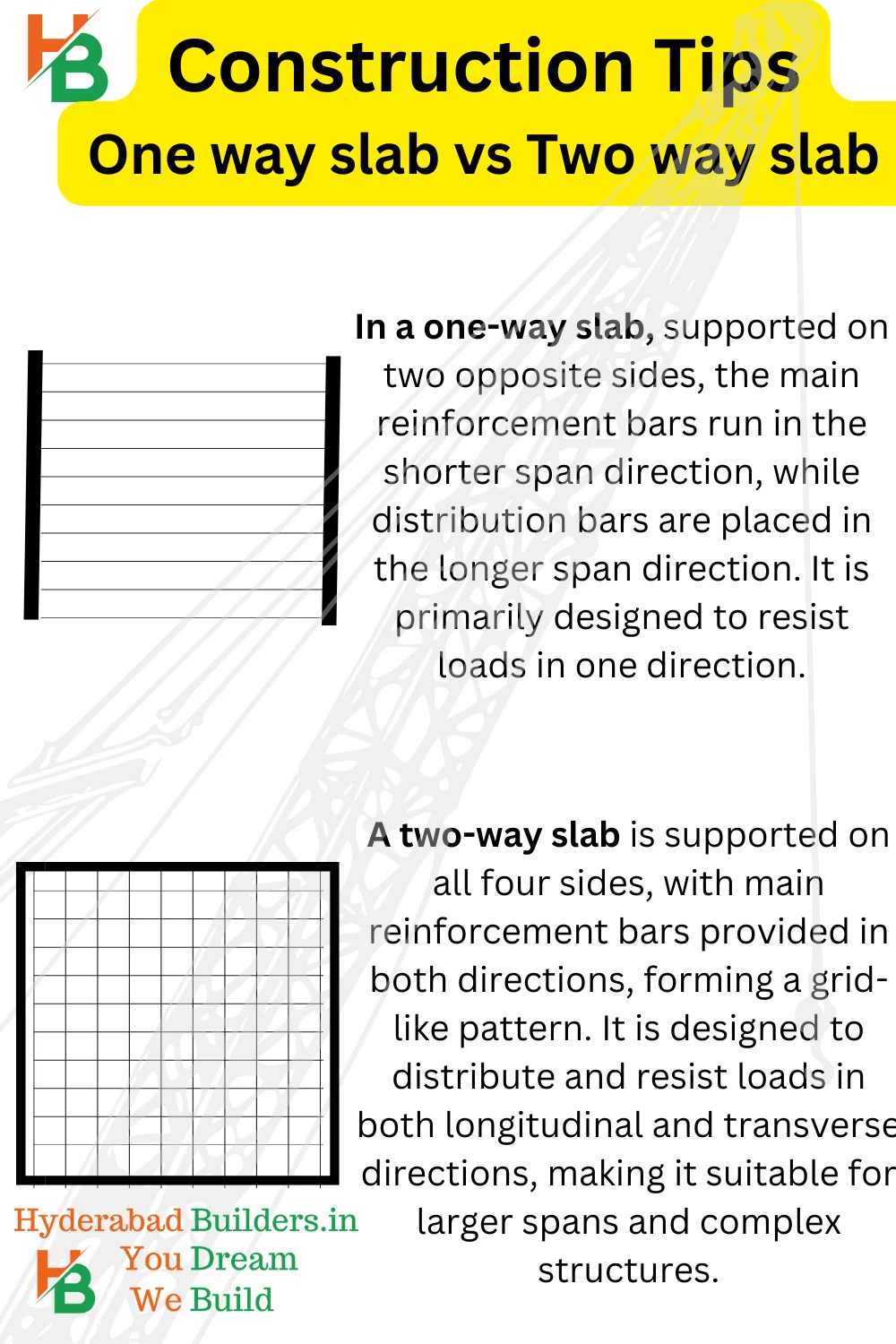

One-Way Slab:

-

-

- A one-way slab is supported on two opposite sides (beams or walls).

- Main reinforcement bars are placed in the shorter span direction, while distribution bars are placed in the longer span direction.

- Suitable for smaller spans.

-

Two-Way Slab:

-

- A two-way slab is supported on all four sides.

- Main reinforcement bars are provided in both directions.

- Suitable for larger spans and more complex structures.

- Flat Slab:

- A flat slab is a two-way reinforced concrete slab with no beams between columns.

- The slab is directly supported on columns, providing a simple and open interior space.

- Ribbed Slab:

- A ribbed slab incorporates a series of closely spaced ribs or beams into the concrete to improve its load-carrying capacity.

- This type of slab reduces the overall weight of the structure and enhances its strength.

- Waffle Slab:

- A waffle slab is a two-way concrete slab reinforced with ribs in both directions.

- The ribbed pattern resembles a waffle, providing a combination of strength and reduced weight.

- Post-Tensioned Slab:

- A post-tensioned slab uses high-strength tendons to apply compression to the concrete after it has been poured and cured.

- This method allows for thinner slabs and increased spans.

- Precast Slab:

- Precast slabs are manufactured off-site and transported to the construction site.

- They offer efficiency and quality control, as they are produced in a controlled environment.

One-Way Slab vs. Two-Way Slab: Key Differences

In structural engineering, the distinction between one-way and two-way slabs is based on the ratio of the longer span (L) to the shorter span (B), influencing the reinforcement configuration and load distribution. Here are the key differences presented in a practical context:

Practical Differences:

- Support Configuration:

- One-Way Slab: Supported on two opposite sides, typically by beams or walls.

- Two-Way Slab: Supported on all four sides, creating a grid-like system of support.

- Reinforcement Placement:

- One-Way Slab: Main reinforcement bars (tension bars) are placed in the shorter span direction, and distribution bars (shear bars) are provided in the longer span direction.

- Two-Way Slab: Main reinforcement bars are placed in both directions, forming a grid pattern to distribute loads in both longitudinal and transverse directions.

- Load Distribution:

- One-Way Slab: Primarily designed to resist loads in one direction, suitable for simple and small-span structures.

- Two-Way Slab: Designed to resist loads in both longitudinal and transverse directions, suitable for larger spans and complex structures.

- Span-to-Depth Ratio:

- One-Way Slab: Typically has a higher span-to-depth ratio, making it suitable for longer spans.

- Two-Way Slab: Generally has a lower span-to-depth ratio, providing stability for loads in multiple directions.

Difference between Oneway and Twoway slab

| Characteristic | One-Way Slab | Two-Way Slab |

|---|---|---|

| Load Distribution | Supported on two opposite sides | Supported on all four sides |

| Bending Resistance | Resists bending in one direction | Resists bending in both directions |

| Reinforcement Placement | Main bars placed in one direction | Main bars placed in both directions |

| Span Ratio Consideration | Economical for L/B > 2 | Suitable for L/B < 2 |

| Grid Pattern | Forms a single grid pattern | Forms a grid pattern in both directions |

| Common Usage | Common in shorter span applications | Common in larger span applications |

Load distribution of one way slab

The load distribution in a one-way slab primarily occurs in the direction perpendicular to the supporting beams or walls. Since one-way slabs are designed to resist bending in only one direction (either the longer span or the shorter span), the primary load distribution is along the shorter span of the slab.

In a one-way slab:

- Load Distribution Direction: Perpendicular to the support.

- Main Reinforcement (Tension Bars): Placed in the shorter span direction to resist tensile forces.

- Distribution Bars (Shear Bars): Provided in the longer span direction to enhance shear strength.

The load is transferred to the supporting elements, typically beams or walls, along the shorter span. This design is suitable for simpler structures with smaller spans where the load distribution in one direction is sufficient to meet the structural requirem

Factors Influencing Choice Between One-way and Two-way Slabs:

- Span Length: One-way slabs are suitable for smaller spans, while two-way slabs are preferred for larger spans.

- Structural Requirements: The load distribution and structural demands influence the choice between one-way and two-way slabs.

- Architectural Design: The desired aesthetic and layout may impact the selection based on the support configuration.

href=”https://in.pinterest.com/pin/1018376534476416631/”>are you pin

One-way slab: It typically has a longer span in one direction and a shorter span in the perpendicular direction. The one way slab aspect ratio is greater than 2.

Two-way slab: It has relatively equal spans in two perpendicular directions. The two way slab aspect ratio is generally less than 2.

| Support Side | Bending Resistance | Span Ratio | |

|---|---|---|---|

| One-way Slab | 2 sides | One direction | L/B > 2 |

| Two-way Slab | 4 sides | Both directions | L/B < 2 |

One-way and two-way slabs refer to different structural systems used in building construction, particularly in reinforced concrete structures. The main difference between them lies in the way they distribute loads and resist bending moments.

Specialized slabs may have additional costs, but long-term benefits could offset initial expenses. Precast slabs can accelerate construction, while complex designs may extend timelines.

Yes, buildings with varying spans or irregular layouts may benefit from a combination for efficiency and optimisation.