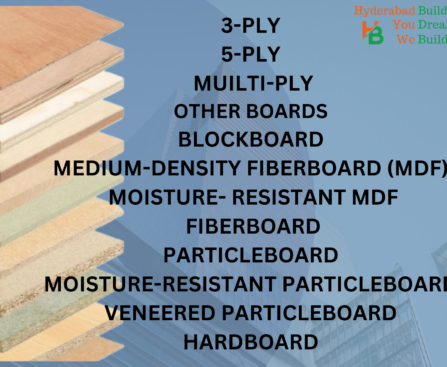

What and Why of Plywood Plywood is a multi-layered product made from thin wood veneers, compressed under heat and pressure with resin or chemical adhesives. This structure makes it stronger than natural wood. Plywood thickness varies from 4mm 5mm 6mm 7mm 8mm 12mm 16mm 18mm 24mm plywood impacting the number of veneer layers and, consequently, its strength. Quality Determinants of Plywood The quality of plywood is influenced by: The type and quality of wood used for veneers. Optimal log size, ideally 4ft x 2ft. The type of resin or adhesive used, with phenol-formaldehyde being superior. Types of Plywood for Interior Work Hardwood Plywood Softwood Plywood Gurjan Plywood Poplar Plywood Mixed Hardwood Plywood (Alternate Plywood) Sanded Plywood Structural Plywood Birch Plywood Beech Plywood Rubberwood Plywood Aircraft Plywood Blockboard-type Plywood Flexible Plywood Shuttering Plywood Rift-cut Plywood Quarter-sliced Plywood Plain-sliced Plywood Detailed types Plywood 1. Hardwood Plywood Primarily made from eucalyptus, known as Safeda in India. Celebrated for its rapid growth and high density. Utilized in specialized applications such as 710-Grade, Marine Grade, or Boiling Waterproof (BWP) products. Crucial to buy from reputable plywood brands to ensure durability. Ideal for environments that demand strong and resilient wood. 2. Softwood Plywood Comprised of lighter woods like pine and cedar. A bit pricier than other types and mainly used for structural purposes like building frameworks. Caution is advised against counterfeit products. Primarily applied in areas where structural integrity is crucial. 3. Gurjan Plywood Originates from Burma, Indonesia, Thailand, and Malaysia. A premium choice but increasingly rare due to logging restrictions. True Gurjan plywood is marked with the IS710-Grade tag. Known for exceptional strength and durability, making it sought-after for high-end construction and furniture. 4. Poplar Plywood Known for its low density, often referred to as cottonwood in India. Main varieties, G48 and W22, cultivated in Punjab and mountainous regions. Produced primarily in Yamuna Nagar, Haryana, typically carrying an MR grade. Lightweight and cost-effective, but limited in durability. 5. Mixed Hardwood Plywood (Alternate Plywood) Combines two timber species, often Eucalyptus and Poplar. Recognizable by alternating core color patterns. Available in grades like IS-303 or MR Grade. Versatile and cost-effective but with limited load-bearing capacity. 6. Sanded Plywood Known for its finely sanded surfaces, providing a smooth finish. Ideal for visible furniture parts like open cabinets and shelves. Comes ready for use, but with a specific application range. May not be as readily available due to its specialized nature. 7. Structural Plywood Designed for heavy-duty applications, capable of withstanding significant pressure and load. Commonly used in construction for framing, beams, and panels. High strength and load-bearing capacity. Generally not suitable for home or office interiors. 8. Birch Plywood Imported primarily from Russia and Finland, known for premium quality. Popular for its stunning finish, even thickness, and resistance to bending. Increasingly popular in India for high-quality furniture and interior applications. More expensive and may not be ideal for warmer climates. 9. Beech Plywood A mix of hardwood and European beech veneer. Inner core of Eucalyptus and a top layer of beech veneer. Provides a stunning wooden look after polishing, akin to veneers. Durable and cost-effective, ideal for a rustic wooden look on a budget. 10. Rubberwood Plywood Manufactured mainly in Kerala, one of the lowest-grade typ 11. Aircraft Plywood Initially used in WWII for British fighter aircraft, made from woods like Mahogany, spruce, and beech. Bonded with high-resistance adhesive, this plywood is high-strength and costly. Not typically available for regular market sale and more of a specialty item for specific requirements. 12. Blockboard-type Plywood Also known as plyboard, mainly used for vertical applications like wall paneling and shutters. Made with solid wood blocks or strips sandwiched between thick wood veneers. Suitable for areas where furniture shutters exceed 5 feet, but not for heavy load-bearing shelves or cabinets. 13. Flexible Plywood Known for its ability to bend into various shapes, used for design purposes like curves, arches, and round pillars. Flexible plywood offers unique design possibilities in furniture making. It should be sourced from well-known brands to ensure quality. 14. Shuttering Plywood Commonly used in the civil industry for constructing beams and roofs. With a hardwood core, this type of plywood is primarily used in construction sectors and not meant for interior or furniture-making purposes. 15. 3-ply Plywood Consists of three layers of veneer, thinner and less expensive than multi-ply options. Often used in decorative applications where weight and cost are considerations. Suitable for light-duty applications and temporary structures. 16. 5-ply Plywood Comprises five layers of veneer, offering a balance between strength and weight. More stable than 3-ply, it is suitable for a variety of interior applications, including furniture and paneling. 17. Multi-ply Plywood Made of multiple layers of veneer, providing excellent strength and stability. Ideal for heavy-duty use in both structural and decorative applications. Often used in areas requiring robust material, like flooring and heavy furniture. 18. Plain-sliced Plywood Features a “cathedral” or “flame” grain pattern, resulting from slicing the log parallel to its length. Common and cost-effective, suitable for cabinetry, furniture, and interior paneling, where a traditional wood appearance is desired. 19. Rift-cut Plywood Produced by slicing the veneer at a slight angle to the radial plane. Features a straight, consistent grain pattern, less prominent than plain-sliced. Often chosen for modern furniture and cabinetry where a uniform look is desired. 20. Quarter-sliced Plywood Created by slicing veneer at a right angle to the growth rings, producing a fine, regular grain pattern. Known for its elegant and upscale appearance. Used in high-end furniture and architectural applications where a refined look is essential. so far we have covered various types of plywood used in Home interiors Building Materials Now let lets look into what are various grades of plywood Some of the plywood facts Plywood Grades Understanding the different grades of plywood is crucial for selecting the right type for your needs, as they indicate quality and durability. 1. Marine Grade Plywood or IS-710 Grade Plywood Highest grade available in India, ideal for interior work and furniture making.