Slab construction cost

Table of Contents

ToggleIntroduction:

Embarking on the construction of a slab, whether for residential or commercial use, necessitates meticulous planning and a thorough examination of several key factors. Material costs, labor expenses, and additional components play pivotal roles in determining the overall expenditure. In this article, we will delve into the intricacies of constructing a 30×60 feet slab, offering a detailed breakdown of expenses and valuable insights into the components that shape the total cost.

What is Slab Construction?

In construction, a slab refers to a flat, horizontal structural element that provides a surface for the occupants or activities within a building. Slabs are an integral part of the building’s structural system, offering support and stability to the structure. They can be made of various materials, such as concrete, reinforced concrete, or even wood, depending on the specific requirements of the building and its intended use.

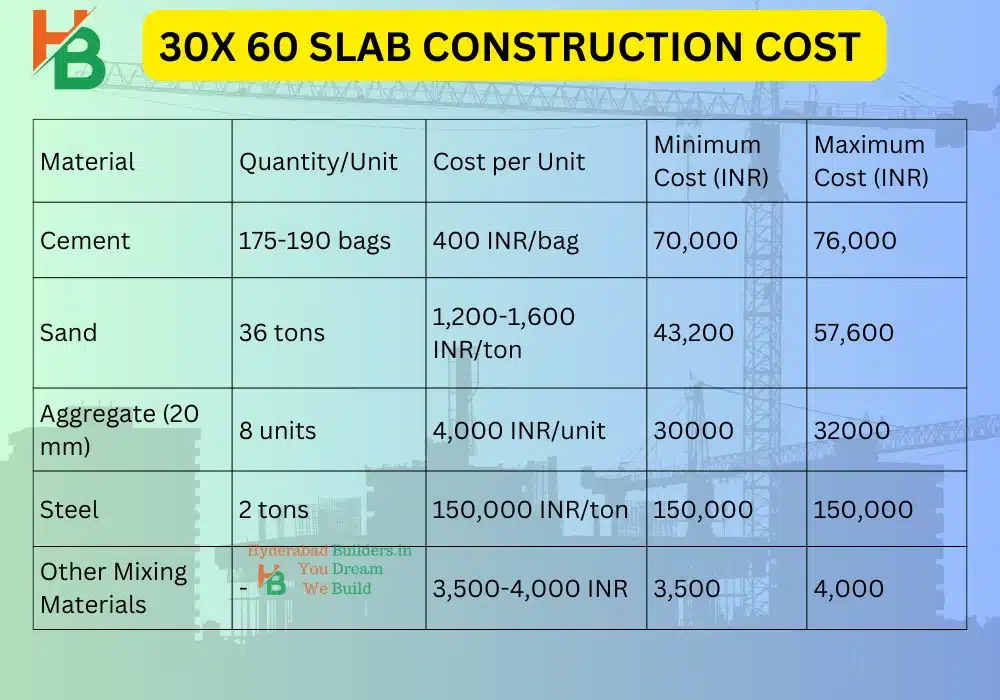

Construction cost for 30×60 feet Slab (Materials Required)

1. Cement required for slab construction:

At the foundation of any construction endeavor lies the crucial factor of cement quality and quantity. For a 30×60 feet slab, a range of 175-190 bags is needed. Priced at 400 INR per bag, the total minimum cost for cement stands at 70,000 INR, while the maximum estimate reaches 76,000 INR.

2. Sand required for slab:

An essential component in the concrete mix, a substantial quantity of sand is imperative. Approximately 36 tons are required for a 30×60 feet slab, with costs ranging from 1,200-1,600 INR per ton. The minimum cost for sand comes to 43,200 INR, while the maximum estimate is 57,600 INR.

3. Aggregate required for 30×60 slab:

Providing strength and stability, the aggregate is priced at 4,000 INR per unit. With 8 units necessary for the slab, the total aggregate cost amounts to 32,000 INR.

4. Steel cost for slab construction :

Reinforcement is paramount for a robust structure, and for a 30×60 feet slab, approximately 2 tons of steel are indispensable. Priced at 75,000 INR per ton, the total steel cost equals 150,000 INR.

5. Other Mixing Materials:

Various additional materials contribute to the concrete mix, with an estimated cost ranging from 3,500-4,000 INR.

Labor Cost for slab construction:

Construction projects heavily rely on skilled labor, and for a 30×60 feet slab, the labor cost is estimated at 150,000 INR. This expense encompasses the expertise required for the proper execution of the construction process.

Total slab Construction Cost:

Summing up all the expenses, the total construction cost for a 30×60 feet slab is estimated at 448,700 INR (minimum estimate). This comprehensive figure includes all material costs, labor expenses, and other necessary components

Slab Construction process

The construction process for the first floor slab involves several key steps to ensure a strong and stable foundation. Here’s a generalized guide for the construction of a first-floor slab:

1. Foundation Preparation:

- Before starting the slab construction, ensure that the foundation for the building has been properly excavated, leveled, and compacted.

- Verify that the footings, if required, are in place and aligned according to the structural design.

2. Formwork Installation:

- Erect formwork to outline the dimensions and shape of the first-floor slab. The formwork can be made of wood, metal, or other materials.

- Ensure that the formwork is properly aligned and securely braced to prevent any displacement during concrete pouring.

3. Reinforcement Placement:

- Install the steel reinforcement (rebar) according to the structural engineer’s specifications. The rebar grid provides tensile strength to the concrete and helps prevent cracking.

- Ensure proper spacing and elevation of the reinforcement within the formwork.

4. Pouring Concrete:

- Once the formwork and reinforcement are in place, concrete is poured into the mold.

- Concrete should be mixed to the specified design strength and consistency.

- Use proper vibration techniques to eliminate air voids and ensure even distribution of concrete.

5. Screeding and Finishing:

- After pouring the concrete, screed the surface to level it. This involves using a straight board to remove excess concrete and create a smooth, flat finish.

- Finishing tools, such as trowels, are used to refine the surface texture and appearance of the concrete.

6. Curing:

- Allow the concrete to cure properly. Curing is a critical step to ensure that the concrete gains strength and durability.

- Depending on the weather conditions and concrete mix, curing may involve covering the slab with wet burlap, applying curing compounds, or keeping the surface moist for a specified period.

7. Removal of Formwork:

- Once the concrete has achieved sufficient strength, carefully remove the formwork. This is usually done after the curing period.

- Take precautions to avoid damaging the edges or surface of the newly formed slab during formwork removal.

8. Quality Checks:

- Conduct quality inspections to ensure that the first-floor slab meets design specifications and construction standards.

- Inspect for any cracks, proper reinforcement placement, and overall structural integrity.

9. Construction of Walls and Superstructure:

- With the first-floor slab in place and cured, construction of the walls and superstructure can proceed.

- Follow the architectural and structural plans for the placement of load-bearing walls and columns.

10. Additional Finishing (Optional):

- Depending on the project requirements, additional finishing touches such as floor coverings, coatings, or surface treatments may be applied to the first-floor slab.

Conclusion:

Understanding the construction cost for a 30×60 feet slab involves a meticulous assessment of material quantities, labor requirements, and associated expenses. By breaking down the costs into specific categories, readers can gain valuable insights into the financial aspects of such a construction project. It is crucial to note that these estimates may vary based on location, market conditions, and specific project requirements. Therefore, seeking detailed quotes from suppliers and contractors is essential for obtaining accurate projections.

Disclaimer:

The information shared is for general understanding only and may not cover all variations in construction practices. Readers are advised to consult with professionals for project-specific guidance, considering factors like local codes and structural requirements. The author and the platform are not liable for any decisions made based on this information. Construction projects involve risks, and readers should seek professional advice for safety and legal compliance.