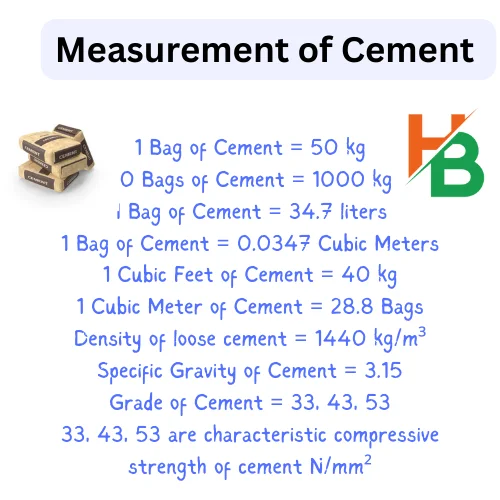

Measurements of cement

Cement is the cornerstone of any construction project, a binding agent that gives structures their strength and durability. In the practice of civil engineering, understanding the properties and measurements of cement is not just academic—it’s a practical necessity. Let’s explore the ten fundamental points about cement that every civil engineer should know.

1. The Standard Measurement Unit: The Bag A typical bag of cement is the quintessential unit, weighing in at 50 kilograms. This standardization simplifies the calculation of how much cement is required for a project.

2. Bulk Handling: The Metric Ton When scaling up, it becomes necessary to think in terms of metric tons. Twenty bags make up a ton, equating to 1000 kilograms, providing a bulk measure that’s essential for large-scale constructions.

3. Volume Considerations Each bag of cement, when poured, would occupy a volume of 34.7 liters. Understanding the volume is crucial when it comes to storage and transportation logistics.

4. Cubic Meter Conversions In civil engineering, the cubic meter is a key unit of measure. A bag of cement translates to 0.0347 cubic meters, a conversion that is indispensable when dealing with concrete mix designs.

5. Weight-to-Volume Ratio Considering the weight, one cubic foot of cement equals 40 kilograms. This ratio is particularly useful in countries where the imperial system is still in use.

6. Cement Bags per Cubic Meter When preparing to mix concrete, it’s important to know that 28.8 bags of cement are needed to fill one cubic meter of volume.

7. Loose Cement Density The density of loose cement is 1440 kg/m³. This density is significantly different from that of compacted cement and can affect the mix and structural calculations.

8. Specific Gravity With a specific gravity of 3.15, cement is denser than water. This property is used to compare the density of cement to that of water, which can influence the curing time and the hydration process.

9. Cement Grades

The strength of cement is designated by its grade—33, 43, or 53. These grades refer to the compressive strength measured in N/mm², indicating the force that cement can withstand after 28 days of setting.

10. Characteristic Compressive Strength Lastly, the characteristic compressive strength is denoted by the same numbers—33, 43, and 53 N/mm². These figures are paramount when choosing the right cement for structural integrity.

Relate article: concrete strength and test procedure, How Ready mix concrete(rmc) is made?

The 50-kilogram bag is a universally accepted standard that facilitates easy calculation and handling across the construction industry.

Thinking in metric tons allows for efficient bulk ordering and planning, essential for large-scale construction projects.

Knowing the volume a bag of cement occupies is crucial for logistical planning, including storage and transportation.

The cubic meter is a fundamental unit for mix designs, enabling accurate proportioning of cement to other concrete component

The weight-to-volume ratio provides a necessary conversion for countries that use the imperial system, ensuring accurate measurements.

Approximately 28.8 bags of 50 kg cement are needed to fill one cubic meter, which is crucial for precise concrete mixing.

The density affects the volume-to-weight ratio, influencing the final mix proportions and the structural calculations

Specific gravity indicates how the density of cement compares to water, affecting hydration and curing times in concrete.

Cement grades like 33, 43, and 53 represent the compressive strength in N/mm², helping select the appropriate cement for various construction needs.

It determines the load the cement can withstand after a set curing period, essential for ensuring structural integrity.