How to check Cement bag before purchasing

Table of Contents

Toggle- How to check Cement bag before purchasing

- Step-by-Step Guide for How to check cement bag

- Step 1: Verify Manufacturer’s Details

- Step 2: Look for the ISI Mark

- Step 3: Assess Cement Grade and Type

- Step 4: Confirm Net Weight

- Step 5: Evaluate the Brand

- Step 6: Check MRP

- Step 7: Ensure ‘Use No Hooks’ Warning

- Step 8: Inspect Batch Number

- Step 9: Note Manufacturer’s Address

- Step 10: Check for Performance Improvers

- Step 11: Confirm IS Code Number

- Storing Cement Bags

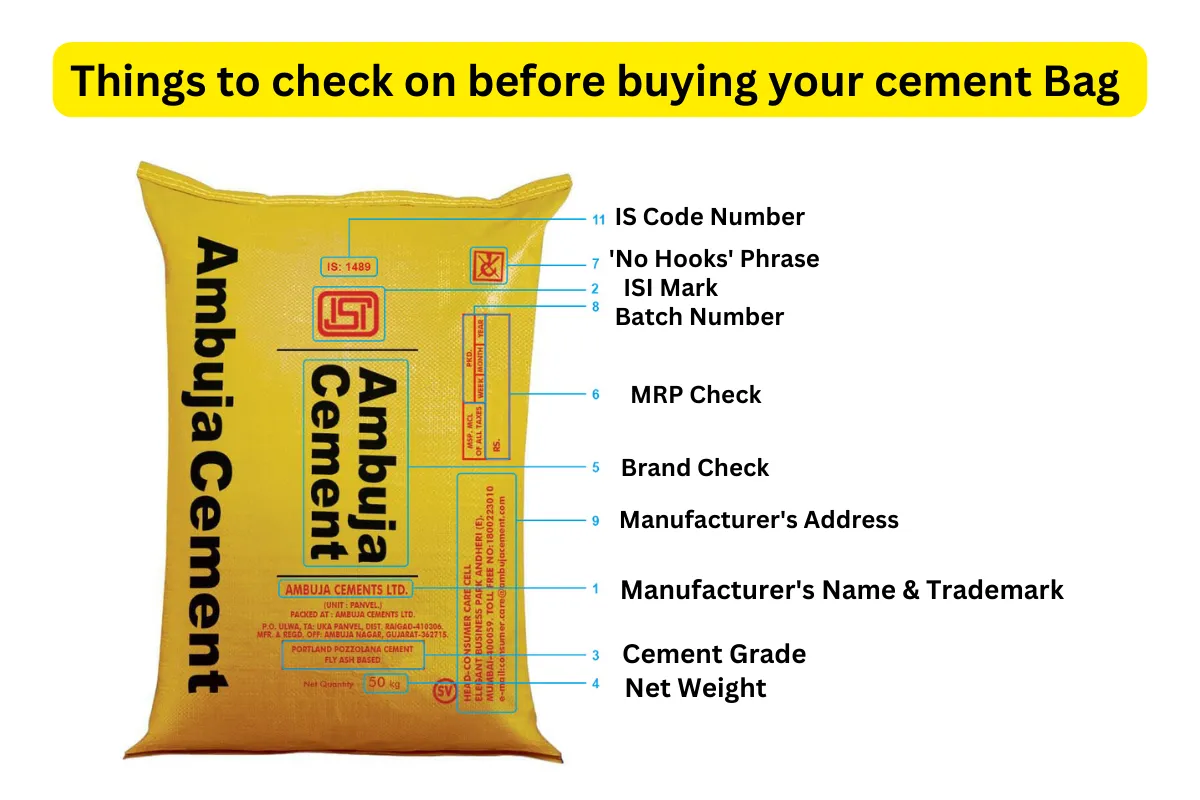

Cement is a crucial construction material, vital for creating concrete and mortar used in RCC framed structures. Its binding properties allow it to mix well with aggregates, forming a strong, homogeneous mixture. However, the quality of cement directly impacts the strength and durability of a structure. Unfortunately, adulteration in cement is common, and laypeople often lack awareness about important considerations when purchasing and storing cement. Hyderabad builders offers valuable insights on this matter.

What to Check Before Buying Cement?

Given the high cost of cement and its significant impact on overall project expenses, it’s essential to ensure you’re buying authentic, high-quality cement. Adulterated or inferior cement can compromise the longevity of a structure. To avoid such risks, there are specific standard specifications you should check on a cement bag before purchase:

Step-by-Step Guide for How to check cement bag

Step 1: Verify Manufacturer’s Details

Check the cement bag for the manufacturer’s name and registered trademark.

Ensure that the printing is clear and without spelling errors to avoid counterfeit products.

Step 2: Look for the ISI Mark

Ensure the ISI mark is printed in black on the cement bag.

This mark indicates compliance with the required specifications.

Step 3: Assess Cement Grade and Type

Identify the grade and type of cement (e.g., Ordinary Portland Cement, 53 Grade).

This information should be clearly printed on the bag.

Step 4: Confirm Net Weight

Check the listed net weight (e.g., 25 Kg, 50 Kg) on the cement bag.

Accurate weight listing is a sign of standard quality.

Step 5: Evaluate the Brand

Choose a well-known, reputable brand.

Review any available technical details or cut-sheets provided by the brand.

Step 6: Check MRP

Verify the Maximum Retail Price (MRP) printed on the bag.

This helps to avoid being overcharged and prevents fraud.

Step 7: Ensure ‘Use No Hooks’ Warning

Look for the phrase ‘Use no Hooks’ or an equivalent symbol.

This is an indication of proper handling guidelines.

Step 8: Inspect Batch Number

Find the batch/control unit number indicating the week, month, and year of packing.

Preferably, use cement that is packed recently (less than 3 months old).

Step 9: Note Manufacturer’s Address

The address should be mentioned on the bag for any future enquiries.

Step 10: Check for Performance Improvers

If any performance improvers are added, their type and percentage should be listed.

Step 11: Confirm IS Code Number

Ensure the correct IS code is printed for the type of cement you are buying (e.g., “IS-12269-1987” for OPC 53 grade).

Storing Cement Bags

After purchasing, it’s crucial to store cement bags properly to maintain their quality. Hyderabad builders has published an article with tips and tricks for effective on-site storage of cement bags. Proper storage ensures the longevity and effectiveness of the cement, thereby contributing to the durability and strength of your construction project.

Checking a cement bag before purchasing is crucial because the quality of cement directly impacts the strength and durability of a structure. It also helps in identifying counterfeit or adulterated cement, which can compromise the longevity of the structure.

Verify the manufacturer’s name and registered trademark on the cement bag. Make sure the printing is clear and free from spelling mistakes to avoid counterfeit products.

The ISI mark, which should be printed in black, indicates that the cement complies with the required specifications and quality standards.

Check the bag for the grade and type of cement, such as “Ordinary Portland Cement, 53 Grade.” This information should be clearly printed on the bag.

Confirming the net weight (e.g., 25 Kg, 50 Kg) ensures that you are getting the correct quantity, and it’s a sign of standard quality control.

Choosing a well-known, reputable brand is important. Review any technical details or cut-sheets provided by the brand to assess quality.

Choosing a well-known, reputable brand is important. Review any technical details or cut-sheets provided by the brand to assess quality.

Verify the Maximum Retail Price (MRP) printed on the bag to avoid being overcharged and to prevent fraud.

The ‘Use No Hooks’ phrase or an equivalent symbol indicates proper handling guidelines to prevent damage to the bag and its contents.

The batch number indicates the week, month, and year of packing. Using cement that is packed recently (usually less than 3 months old) is advisable for better quality.

The manufacturer’s address is important for any future enquiries or in case of issues with the cement quality.

Performance improvers, if added, enhance certain properties of the cement. If present, their type and percentage should be listed on the bag.

Ensure the correct IS code (e.g., “IS-12269-1987” for OPC 53 grade) is printed on the cement bag, indicating it meets specific standards.

Store cement bags in a dry, moisture-free area. Avoid direct contact with the ground and walls. Proper storage maintains the cement’s quality and ensures its effectiveness for your construction project.