The History of Steel and Evolution of TMT Bars

Table of Contents

ToggleThe history of steel TMT (Thermo-Mechanically Treated) bars is a remarkable tale of technological advancement and its significant impact on construction practices. From the inception of steel production in the 13th century BC to its modern high-tech applications, steel has been a cornerstone of economic, social, and cultural development. It has formed the backbone of modern economies, particularly in the field of construction, where it pairs perfectly with Reinforced Cement Concrete (RCC), first invented in 1867.

How did the ancients make steel?

1. Bloomery Process

The bloomery process was one of the earliest methods of producing iron and steel. This method involves heating iron ore and charcoal in a furnace at relatively low temperatures (about 1200-1300°C). The resulting product, known as a “bloom,” was a spongy mass of iron and slag.

- Process:

- Iron ore and charcoal are layered in a small furnace.

- Air is blown into the furnace to raise the temperature.

- The heat causes the iron ore to reduce, and iron particles begin to stick together.

- The bloom is extracted and hammered to remove the slag, consolidating the iron and introducing carbon from the charcoal, which can produce a crude form of steel.

2. Crucible Steel (Wootz Steel)

Originating in India around the early centuries CE, crucible steel, or wootz steel, was renowned for its high quality and unique patterns.

- Process:

- High-purity iron, along with a source of carbon (often charcoal), was placed in a sealed ceramic crucible.

- The crucible was heated to high temperatures (about 1400-1500°C) in a furnace.

- The iron absorbed carbon and melted, forming high-carbon steel.

- After cooling, the steel ingots were known for their toughness and ability to hold a sharp edge. Wootz steel was later used to produce the famous Damascus steel swords.

3. Pattern Welding

Used by various cultures including the Vikings and other early medieval Europeans, pattern welding involved forging together layers of iron and steel to produce a composite material.

- Process:

- Strips of iron and steel were welded together by heating and hammering.

- The billet was repeatedly folded and twisted to create intricate patterns.

- This process improved the material’s mechanical properties by combining the toughness of iron with the hardness of steel.

Who Invented Steel?

The invention of steel cannot be attributed to a single individual or a precise point in history. Instead, it evolved over millennia through contributions from various ancient civilizations. The knowledge of ironworking and steelmaking spread and improved over time:

- Early Iron Age: Around 1200 BCE, iron began to be used widely in the Near East, India, and later in Europe.

- India: By around 300 BCE, Indian metallurgists had developed high-quality crucible steel, known as wootz steel.

- China: Around the 5th century CE, Chinese metallu

The Father of Steel: Henry Bessemer

To understand the evolution of TMT bars, it’s essential to first appreciate the monumental contributions of Henry Bessemer. Widely regarded as the father of the steel industry, Bessemer’s invention of the Bessemer process in 1855 revolutionized steel production. This groundbreaking method allowed for the mass production of steel at a fraction of the previous cost, reducing the price from £50-60 per ton to £6-7 per ton. Bessemer’s process involved blowing air through molten pig iron to oxidize and remove impurities, significantly speeding up production and improving the quality of steel. This innovation made steel accessible for widespread use in construction, transportation, and machinery, revolutionizing industries and paving the way for modern infrastructure. Bessemer’s contributions transformed steel into a fundamental material for the industrial age, underpinning advancements in bridges, buildings, railroads, and more.

Steel and RCC: A Perfect Combination

The development of reinforced cement concrete (RCC) in 1867 marked a pivotal moment in construction history. Steel and concrete are fundamental Construction Materials, with concrete being extremely strong in compression but weak in tension. Steel, conversely, is strong in tension, providing the necessary tensile strength to concrete. This complementary relationship makes steel the ideal reinforcement for concrete structures. Additionally, the thermal expansion of both materials is nearly identical, ensuring that they expand and contract at similar rates under temperature changes, further enhancing their compatibility. Steel’s excellent bonding with concrete and its bendability make it indispensable in reinforced concrete structures.

Evolution of TMT Bars

Building on the synergy between steel and concrete, the evolution of reinforcement materials has been crucial. In the early days of steel manufacturing, mild steel (MS) bars were predominantly used for reinforcing concrete. However, after World War II, higher strength deformed rebars gained popularity. These included hot-rolled and cold twisted deformed (CTD) rebars. CTD bars offered a yield stress of approximately 415 MPa, significantly higher than the 250 MPa of MS bars, despite having similar chemical compositions. This advancement in physical strength was a significant leap forward.

The demand for even stronger reinforcements led to the development of Thermo-Mechanically Treated (TMT) bars. The TMT process involves heating rebars to around 900°C and then rapidly cooling them to around 450°C. This process creates a softer ferrite-pearlite core with a harder martensite outer layer, enhancing the strength and flexibility of the bars. TMT bars were first introduced in 1979 and were initially available in grades Fe 415 and Fe 500. These bars quickly gained global popularity due to their superior ductility, strength, and bending ability.

The Evolution and Impact of Steel and TMT Bars in India

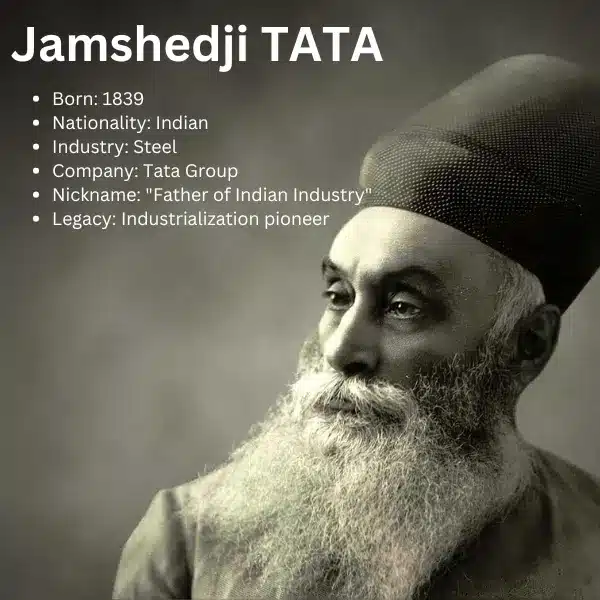

The steel industry in India has a rich history and has undergone significant transformations over the years. From the pioneering efforts of Jamshedji Tata, the father of the Indian steel industry, to the introduction of advanced TMT bars, steel has played a crucial role in the country’s industrial and economic development.

Jamshedji Tata: Father of the Indian Steel Industry

Jamshedji Tata is revered as the father of the steel industry in India. He established India’s first steel plant, Tata Iron and Steel Company Limited (now Tata Steel), in 1907 in Jamshedpur, Jharkhand. Tata’s vision and pioneering efforts laid the foundation for the Indian steel industry, contributing significantly to India’s industrial development. His commitment to industrialization, combined with his innovative approaches and entrepreneurial spirit, earned him this title and solidified his legacy in the history of Indian industry.

Historical Context of Steel in India

Steel production in India dates back to as early as 400 BCE, but it was the establishment of Bengal Iron Works in 1874 and later Tata Iron and Steel Company in 1907 that put India on the global steel map. Initially, mild steel bars were used in construction, but as the industry evolved, so did the materials, leading to the advent of TMT bars.

Transition to TMT Bars

In the mid-1960s, India transitioned from plain mild steel rods to Cold Twisted Deformed (CTD) bars, which quickly replaced MS bars due to their simpler production process and efficiency. TMT (Thermo Mechanically Treated) bars were introduced in India between 1980 and 1985, with most steel companies manufacturing grades Fe 500 and Fe 550.

TMT Bar Grades and Their Applications

To understand the versatility and applications of TMT bars, it’s crucial to look at the different steel grades available:

Fe 415: Known for its flexibility and ease of bending. Subtypes include Fe 415S and Fe 415D. Widely used for residential construction.

Fe 500: Offers higher strength compared to Fe 415. Subtypes include Fe 500D and Fe 500S, which provide extra ductility and stability. Ideal for multi-story buildings.

Fe 550: Known for its high tensile strength. Suitable for large industrial constructions.

Fe 600: The strongest TMT bar grade. Recommended for critical structures like bridges, tunnels, and towers due to its superior strength.

The Role of TMT Bars in Modern Construction

The introduction and evolution of TMT bars have been pivotal in the advancement of construction technology in India. TMT bars offer better strength, flexibility, and reliability compared to their predecessors. They have become an essential component in ensuring the durability and strength of modern structures, from residential buildings to large industrial projects.

Case Studies: Real-World Impact of TMT Bars

Bandra-Worli Sea Link: The iconic Bandra-Worli Sea Link in Mumbai is a testament to the strength and reliability of TMT bars. This cable-stayed bridge, completed in 2010, required materials that could withstand the harsh coastal environment and high traffic loads. TMT bars were crucial in providing the necessary tensile strength and durability.

Mumbai Monorail: The Mumbai Monorail project, inaugurated in 2014, is another example where TMT bars played a vital role. The elevated tracks and supporting structures needed reinforcement that could offer both flexibility and strength, ensuring the safety and longevity of the infrastructure.

Conclusion

The evolution of TMT bars has been pivotal in the advancement of construction technology. From their inception to the various grades available today, TMT bars have continually improved, offering better strength, flexibility, and reliability. Companies like Tata Steel Limited, Steel Authority of India Limited (SAIL), JSW Steel Limited, Jindal Steel and Power Limited (JSPL), Essar Steel India Limited, Bhushan Steel Limited (now part of Tata Steel BSL), Rashtriya Ispat Nigam Limited (RINL), ArcelorMittal Nippon Steel India (AM/NS India), Electrosteel Steels Limited, and Welspun Corp Limited have played a significant role in manufacturing high-quality TMT bars, meeting diverse construction needs and contributing to economic growth. Whether for residential buildings or large industrial projects, TMT bars remain an essential component, ensuring the durability and strength of modern structures.

Steel was not invented by a single person; it evolved over time with significant early contributions from ancient civilizations like India and China.

The modern steel industry began with Henry Bessemer’s invention of the Bessemer process in 1856 and was significantly expanded by industrialists like Andrew Carnegie.

Ancient methods included the bloomery process, crucible steel (wootz), pattern welding, and early blast furnaces, combining iron and carbon through heating and forging.

The Bessemer process, invented in 1856, involves blowing air through molten pig iron to remove impurities and produce steel.

Wootz steel, produced in ancient India, is famous for its high quality and was used to create the legendary Damascus steel swords.

Pattern welding involves forging together layers of iron and steel, used by Vikings and early medieval Europeans to enhance strength and flexibility.

Blast furnaces, developed in ancient China, allowed for the mass production of cast iron and later facilitated the production of steel.

Jamsetji Tata, known as the “Father of Indian Industry,” founded Tata Steel and played a crucial role in India’s industrialization

Damascus steel, renowned for its strength and sharpness, was made from wootz steel and characterized by distinctive patterns on the blades.