Introduction

The backbone of modern construction, Thermo-Mechanically Treated (TMT) bars, are crucial for the structural integrity of buildings. Among these, Fe 415, Fe 500, and Fe 550D grades are widely recognized for their distinctive properties and applications. This article delves into these specific grades, highlighting their characteristics, manufacturing processes, and suitability for various construction projects.

Why is steel is used in concrete

Table of Contents

ToggleConcrete, by its nature, has high compressive strength but low tensile strength. This means it can withstand loads that tend to compress it but would crack under loads that tend to stretch or bend it. To compensate for this weakness, steel reinforcement bars (rebar), which have high tensile strength, are added to the concrete at the locations where the tensile stresses are anticipated to be the highest.

When concrete is poured around steel rebars, it forms a solid bond with the steel as it cures. This bond is critical to ensure that the two materials act together under load. The steel bars carry the tensile forces while the concrete carries the compressive forces. The result is a homogeneous structural material that can withstand a variety of stresses and loads, making it ideal for a wide range of construction applications, including beams, floors, bridges, and foundations.

What is TMT Bars: A Brief Overview

TMT bars are a result of a unique metallurgical process called thermo-mechanical treatment. This process imparts superior strength, ductility, and weldability to the steel, making it ideal for reinforcing concrete in construction projects.

They come in various grades, which signify the yield strength, ductility, and tensile strength of the bars. These grades are standardized and each has specific characteristics that make them suitable for different types of construction requirements.

Common grades of TMT bars include:

-

Fe 415: This is a common grade used for residential buildings because of its excellent bendability.

-

Fe 500: A higher strength variant than Fe 415, providing a balance between strength and ductility.

-

Fe 550: This grade has even higher tensile strength and is used for structures that require additional strength.

-

Fe 600: This is used for heavy-duty structures like bridges and industrial buildings.

-

Fe 500D: The ‘D’ here signifies higher ductility. This grade is particularly used in areas prone to earthquakes due to its high ductility and tensile strength.

-

Fe 550D: Similar to Fe 500D but with higher yield strength.

-

Fe 415 TMT Bars: Properties and Applications

Fe 415 bars, known for their excellent ductility and higher elongation, are the preferred choice in earthquake-prone areas. With a yield strength of 415 N/mm², they offer a perfect blend of strength and flexibility, reducing the risk of structural failure during seismic activities. These bars are typically used in residential buildings, low-rise structures, and projects where bending and re-bending of bars are required.

Fe 500 TMT Bars: A Balance of Strength and Flexibility

Fe 500 grade bars, with a yield strength of 500 N/mm², strike a balance between strength and flexibility. They are stronger than Fe 415 bars, making them suitable for multi-storey buildings, bridges, and industrial structures. Despite their high strength, they maintain adequate ductility, which is essential for supporting dynamic loads.

Fe 550D TMT Bars: The High-Strength Alternative

Fe 550D grade bars represent the high-strength segment of TMT bars with a yield strength of 550 N/mm². They are designed for heavy-duty construction projects such as high-rise buildings, long-span bridges, and industrial structures requiring a robust framework. The ‘D’ in Fe 550D denotes enhanced ductility, making these bars a reliable choice for projects demanding high load-bearing capacity.

Manufacturing Process: A Key Differentiator

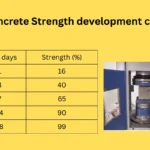

The manufacturing process of TMT bars involves rapid quenching of hot steel bars, followed by air cooling. This process forms a hardened surface layer while maintaining a softer core, thereby giving the bars their unique strength and ductility. The variations in temperature and cooling rates in the manufacturing process lead to the different grades of TMT bars.

Chemical Composition and Mechanical Properties of fe415, fe 500 and fe 550d

Each grade of TMT bar has a specific chemical composition and set of mechanical properties. Fe 415 typically contains a lower carbon content compared to Fe 500 and Fe 550D, which contributes to its higher elongation and ductility. Fe 500 and Fe 550D, with slightly higher carbon content, offer greater strength but with controlled proportions of sulphur and phosphorus to ensure ductility.

Applications in Construction

Fe 415: Ideal for residential and commercial buildings in seismic zones.

Fe 500: Suitable for multi-storey buildings and industrial applications.

Fe 550D: Best for heavy-duty infrastructure projects and high-rise constructions.

Difference between Fe500 vs Fe550 D

| Property / Grade | Fe 500 TMT Grade Bar | Fe 550D TMT Grade Bar |

|---|---|---|

| Tensile Strength | Exceeds 545.0 N/mm² | Exceeds 585.0 N/mm² |

| Chemical Composition | Iron, Carbon (0.3%), Sulphur (0.055%), Phosphorus (0.055%) by mass, S+P ≈ 0.105% | Iron, Carbon (0.25%), Sulphur (0.04%), Phosphorus (0.04%) by mass, S+P ≈ 0.07% |

| Yield Strength (fy) | 500 N/mm² | 550 N/mm² |

| Ultimate Tensile Strength (fu) | 545 N/mm² | 585 N/mm² |

| Elongation | 12 | 16 |

| TS/YS Ratio | 1.09 | 1.08 |

| Applications | Multi-storey and commercial buildings, private ventures, earthquake-resistant structures | Large-scale construction projects, mechanical undertakings, scaffolds, high-weight-bearing structures, underground and marine projects |

8. Concluding Thoughts

Choosing the right grade of TMT bar is pivotal for the safety, durability, and longevity of any construction project. Fe 415, Fe 500, and Fe 550D each serve unique purposes and are selected based on the structural demands and environmental considerations of the project. Understanding these grades helps architects, engineers, and builders make informed decisions, ensuring the structural integrity and sustainability of modern constructions.