Introduction: In every construction, where longevity and structural integrity is important, the often-overlooked process of curing of concrete plays a pivotal role. Curing is more than just a step; it’s a key factor that influences the strength, durability, and overall performance of construction materials, particularly concrete. This article delves into the importance of curing, exploring methods, best practices, and the consequences of neglecting this critical aspect.

What is Curing?

Table of Contents

ToggleCuring is the controlled process of maintaining adequate moisture, temperature, and time for concrete or other construction materials to achieve optimal hydration and comprehensive strength. It is the phase where cement reacts with water, forming a strong and durable matrix.

Importance of Proper Curing of concrete:

- Strength Development: Proper curing enhances the hydration process, allowing concrete to achieve its designed strength. Inadequate curing can result in lower strength and compromised structural performance.

- Durability: Cured concrete is more resistant to environmental factors such as freeze-thaw cycles, chemical exposure, and abrasion, ensuring long-term durability.

- Crack Prevention: Curing minimizes the likelihood of cracks, safeguarding the structural integrity and aesthetic appeal of constructions.

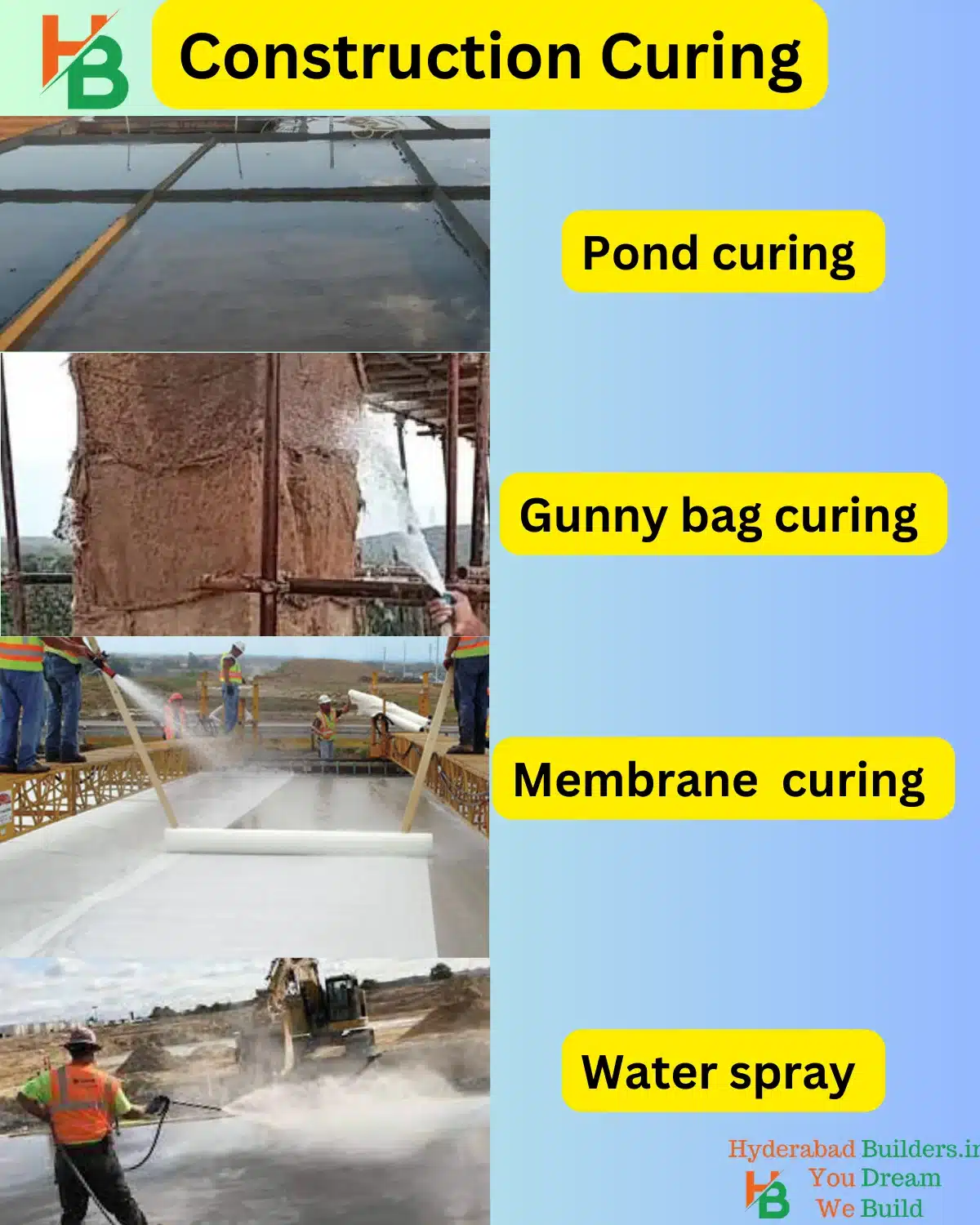

Methods of Curing:

Water Curing:

Process: Involves submerging the concrete in water or consistently wetting its surface.

Effectiveness: Highly effective for preventing moisture loss, particularly crucial during the initial stages of curing.

Applications: Widely used for various concrete structures to ensure adequate hydration and strength development.

Steam Curing:

Process: Accelerates curing by applying heat and steam to the concrete surface.

Suitability: Ideal for projects requiring rapid strength development, such as precast concrete elements.

Benefits: Shortens the curing period, allowing for faster project timelines and increased production efficiency.

Membrane Curing:

Application: Apply a curing membrane, such as curing compounds or sheets, to the concrete surface.

Procedure: Ensure uniform coverage, and the membrane forms a continuous layer.

Purpose: The membrane acts as a barrier, preventing moisture evaporation and creating a controlled curing environment.

Considerations: Commonly used when water curing is impractical, such as in windy or hot conditions.

Electrical Curing:

Installation: Embed electrical resistive elements or wires within the concrete.

Activation: Apply electrical currents to generate heat within the concrete.

Procedure: Maintain precise control over the temperature to accelerate the curing process.

Applications: Commonly used in precast concrete elements or when traditional curing methods are challenging.

Curing Period of Concrete:

Initiation: Commences immediately after the concrete is placed and finished.

Duration: Typically spans a minimum of seven days, but varies based on factors like mix design, ambient conditions, and project requirements.

Method: Involves keeping the concrete consistently moist during the specified curing period.

Importance: Allows sufficient time for hydration, ensuring the concrete attains the desired strength and durability.

Infrared Radiation Curing:

Equipment: Use infrared radiation sources, such as lamps or heaters.

Procedure: Direct infrared radiation onto specific areas or the entire concrete surface.

Advantages: Enables targeted heating, speeding up curing in localized regions. Particularly beneficial in cold weather conditions.

Acrylic Compound:

Application: Spray or brush the acrylic compound onto the concrete surface.

Formation: Forms a protective film that acts as a barrier against water evaporation.

Purpose: Retains moisture on the concrete surface, promoting proper curing.

Common Use: Applied to exterior concrete surfaces to prevent rapid moisture loss, especially in sunny or windy conditions

Chemical Curing:

Process: Involves using curing compounds applied to the concrete surface to create a moisture-retaining film.

Ideal Applications: Well-suited for large-scale projects where manual curing may be impractical or challenging.

Advantages: Ensures uniform curing, reduces labor requirements, and provides a protective layer against premature drying.

Best Practices for Concrete Curing:

-

- Timely Initiation:

- Importance: Begin curing immediately after concrete setting to prevent premature moisture loss.

- Rationale: Early initiation ensures optimal hydration, contributing to the concrete’s long-term strength and durability.

- Duration and Frequency:

- Guidelines: Maintain curing for a recommended period, typically a minimum of seven days.

- Execution: Regularly wet the concrete surface or apply curing compounds to sustain continuous hydration.

- Objective: Adequate curing duration and frequency are vital for achieving the desired concrete strength and durability.

- Temperature Considerations:

- Adaptation: Adjust curing methods based on ambient temperature conditions.

- Prevention: Avoid curing during extreme weather conditions, such as high winds or direct sunlight, to prevent thermal cracking.

- Outcome: Proper temperature considerations contribute to the prevention of surface defects and ensure consistent curing results.

- Timely Initiation:

Consequences of Inadequate Curing:

-

Reduced Strength:

- Issue: Inadequate curing results in incomplete hydration of cement particles.

- Effect: Reduced concrete strength, compromising the structural integrity of the construction.

- Impact: Weakened concrete may lead to structural failures and pose safety risks.

-

Increased Permeability:

- Problem: Poorly cured concrete is more vulnerable to water penetration.

- Outcome: Increased permeability, leading to durability issues as water ingress can cause corrosion of reinforcing steel.

- Concern: Reduced resistance to environmental factors, affecting the long-term performance of the structure.

-

Cracking and Surface Defects:

- Challenge: Insufficient moisture during curing raises the risk of cracks and surface imperfections.

- Result: Cracking compromises the aesthetics and functionality of the concrete.

- Consequence: Structural integrity is compromised, and repairs may be required, increasing maintenance costs.