The History of Steel and Evolution of TMT Bars The history of steel TMT (Thermo-Mechanically Treated) bars is a remarkable tale of technological advancement and its significant impact on construction practices. From the inception of steel production in the 13th century BC to its modern high-tech applications, steel has been a cornerstone of economic, social, and cultural development. It has formed the backbone of modern economies, particularly in the field of construction, where it pairs perfectly with Reinforced Cement Concrete (RCC), first invented in 1867. How did the ancients make steel? 1. Bloomery Process The bloomery process was one of the earliest methods of producing iron and steel. This method involves heating iron ore and charcoal in a furnace at relatively low temperatures (about 1200-1300°C). The resulting product, known as a “bloom,” was a spongy mass of iron and slag. Process: Iron ore and charcoal are layered in a small furnace. Air is blown into the furnace to raise the temperature. The heat causes the iron ore to reduce, and iron particles begin to stick together. The bloom is extracted and hammered to remove the slag, consolidating the iron and introducing carbon from the charcoal, which can produce a crude form of steel. 2. Crucible Steel (Wootz Steel) Originating in India around the early centuries CE, crucible steel, or wootz steel, was renowned for its high quality and unique patterns. Process: High-purity iron, along with a source of carbon (often charcoal), was placed in a sealed ceramic crucible. The crucible was heated to high temperatures (about 1400-1500°C) in a furnace. The iron absorbed carbon and melted, forming high-carbon steel. After cooling, the steel ingots were known for their toughness and ability to hold a sharp edge. Wootz steel was later used to produce the famous Damascus steel swords. 3. Pattern Welding Used by various cultures including the Vikings and other early medieval Europeans, pattern welding involved forging together layers of iron and steel to produce a composite material. Process: Strips of iron and steel were welded together by heating and hammering. The billet was repeatedly folded and twisted to create intricate patterns. This process improved the material’s mechanical properties by combining the toughness of iron with the hardness of steel. Who Invented Steel? The invention of steel cannot be attributed to a single individual or a precise point in history. Instead, it evolved over millennia through contributions from various ancient civilizations. The knowledge of ironworking and steelmaking spread and improved over time: Early Iron Age: Around 1200 BCE, iron began to be used widely in the Near East, India, and later in Europe. India: By around 300 BCE, Indian metallurgists had developed high-quality crucible steel, known as wootz steel. China: Around the 5th century CE, Chinese metallu The Father of Steel: Henry Bessemer To understand the evolution of TMT bars, it’s essential to first appreciate the monumental contributions of Henry Bessemer. Widely regarded as the father of the steel industry, Bessemer’s invention of the Bessemer process in 1855 revolutionized steel production. This groundbreaking method allowed for the mass production of steel at a fraction of the previous cost, reducing the price from £50-60 per ton to £6-7 per ton. Bessemer’s process involved blowing air through molten pig iron to oxidize and remove impurities, significantly speeding up production and improving the quality of steel. This innovation made steel accessible for widespread use in construction, transportation, and machinery, revolutionizing industries and paving the way for modern infrastructure. Bessemer’s contributions transformed steel into a fundamental material for the industrial age, underpinning advancements in bridges, buildings, railroads, and more. Steel and RCC: A Perfect Combination The development of reinforced cement concrete (RCC) in 1867 marked a pivotal moment in construction history. Steel and concrete are fundamental Construction Materials, with concrete being extremely strong in compression but weak in tension. Steel, conversely, is strong in tension, providing the necessary tensile strength to concrete. This complementary relationship makes steel the ideal reinforcement for concrete structures. Additionally, the thermal expansion of both materials is nearly identical, ensuring that they expand and contract at similar rates under temperature changes, further enhancing their compatibility. Steel’s excellent bonding with concrete and its bendability make it indispensable in reinforced concrete structures. Evolution of TMT Bars Building on the synergy between steel and concrete, the evolution of reinforcement materials has been crucial. In the early days of steel manufacturing, mild steel (MS) bars were predominantly used for reinforcing concrete. However, after World War II, higher strength deformed rebars gained popularity. These included hot-rolled and cold twisted deformed (CTD) rebars. CTD bars offered a yield stress of approximately 415 MPa, significantly higher than the 250 MPa of MS bars, despite having similar chemical compositions. This advancement in physical strength was a significant leap forward. The demand for even stronger reinforcements led to the development of Thermo-Mechanically Treated (TMT) bars. The TMT process involves heating rebars to around 900°C and then rapidly cooling them to around 450°C. This process creates a softer ferrite-pearlite core with a harder martensite outer layer, enhancing the strength and flexibility of the bars. TMT bars were first introduced in 1979 and were initially available in grades Fe 415 and Fe 500. These bars quickly gained global popularity due to their superior ductility, strength, and bending ability. The Evolution and Impact of Steel and TMT Bars in India The steel industry in India has a rich history and has undergone significant transformations over the years. From the pioneering efforts of Jamshedji Tata, the father of the Indian steel industry, to the introduction of advanced TMT bars, steel has played a crucial role in the country’s industrial and economic development. Jamshedji Tata: Father of the Indian Steel Industry Jamshedji Tata is revered as the father of the steel industry in India. He established India’s first steel plant, Tata Iron and Steel Company Limited (now Tata Steel), in 1907 in Jamshedpur, Jharkhand. Tata’s vision and pioneering efforts laid the foundation for the Indian steel industry, contributing significantly to India’s industrial development.

Looking for the most auspicious dates and Griha Pravesh Muhurat in 2024? If so, keep reading this article. This article will show you the most suitable Griha Pravesh Muhurats available in 2024. Remember that muhurats are given here as per Hindu Calendar and Panchangam. What is Griha Pravesh Muhurat? The term “Griha Pravesh” is a combination of two words—Griha, which denotes a home, and Pravesh, which denotes entry. To enter a residence at a fortunate hour and day is what the Hindi phrase “Griha Pravesh Muhurat or Gruhapravesam Muhurat” means in English. The Griha Pravesh muhurat ensures that the residents of that particular home remain healthy, happy, and content. Why Griha Pravesh Muhurat is important to enter in to a new house? Have you ever wondered why people are always looking for auspicious dates and Griha Pravesh muhurats to enter a new home? Some people think it is just superstition, but there are actually many reasons why this is an important tradition in Hinduism. The Griha Pravesh Muhurat is determined based on various factors such as the positions of celestial bodies, planetary alignments, Tithi (lunar day), Nakshatra (lunar mansion), and other astrological considerations. These factors are analyzed by priests or astrologers to identify the most auspicious time frames for conducting the housewarming rituals. Performing Griha Pravesh during a favorable Muhurat is believed to ensure the well-being, prosperity, and harmony of the residents in the new home. It is a significant tradition observed by many Hindu families to seek the blessings of the divine and to embark on a new phase of life with positivity and auspiciousness. It is always best to check the authentic Hindu calendar or Panchangam to know the favorable dates for entering a new home in 2024. So, select the best muhurat for Griha Pravesh in 2024 so that God can bless you with love and peace in your family. Auspicious Dates for Griha Pravesh in 2024 Moving into a new house is one of the most exciting times of your life. But there are many things to consider before you officially move in. One of them is whether or not it is auspicious to do so on a certain day. You can also perform Griha Pravesh rituals to ensure that your new home is healthy and happy. Check out the following auspicious dates for Griha Pravesh in 2024 Date Day Tithi Nakshatra Timings March 2, 2024 Saturday Saptami Anuradha 2:42 AM to 6:44 AM, Mar 3 March 6, 2024 Wednesday Ekadashi Uttara Ashadha 2:52 AM to 4:13 AM, Mar 7 March 11, 2024 Monday Dwitiya Uttara Bhadrapada, Revati 10:44 AM to 6:34 AM, Mar 12 March 15, 2024 Friday Saptami Rohini 10:09 PM to 06:29 AM, Mar 16 March 29, 2024 Friday Panchami Anuradha 08:36 PM to 06:13 AM, Mar 30 March 30, 2024 Saturday Panchami Anuradha 06:13 AM to 09:13 PM Why April 4, 2024, is considered a good day for Griha Pravesh: Tithi (Dashami): The Dashami tithi represents the tenth day of the lunar month in the Hindu calendar. Dashami is associated with positivity, auspiciousness, and new beginnings. It is considered favorable for starting new ventures and ceremonies like Griha Pravesh. Nakshatra (Uttara Ashadha): Uttara Ashadha nakshatra is ruled by the deity Vishvadevas, the universal gods. It signifies prosperity, growth, and success. Griha Pravesh performed under this nakshatra is believed to bring blessings from the divine forces, ensuring stability and harmony in the new home. Timings (06:29 PM to 09:47 PM): The timings provided fall within the evening, which is often considered an auspicious time for Griha Pravesh ceremonies. Evening ceremonies are believed to invite positive energies and blessings for the household members. Additionally, the specific time window aligns with the favorable positions of celestial bodies, enhancing the auspiciousness of the occasion. Overall, April 4, 2024, presents an opportune moment for Griha Pravesh due to the combination of the Dashami tithi, Uttara Ashadha nakshatra, and the auspicious evening timings. Conducting the ceremony on this day is believed to usher in prosperity, happiness, and auspiciousness in the new home. Griha Pravesh Muhurat in May to October 2024 Unfortunately, there are no auspicious Griha Pravesh Muhurats available from May to October 2024. The entire span of these months is considered inauspicious for initiating housewarming ceremonies according to astrological beliefs. During this period, it’s advisable to postpone any plans for Griha Pravesh ceremonies and wait for more favorable times. Conducting such ceremonies during inauspicious periods may invite negative energies and hinder the harmonious transition into your new home. It’s essential to prioritize the well-being and prosperity of your family by adhering to astrologically auspicious timings. Stay patient and consult with astrologers or experts to determine the most propitious dates for your Griha Pravesh ceremony once the inauspicious period passes. Griha Pravesh Muhurats for Nutan Griha Pravesh in November 2024 Date & Day Timing (Muhurat) Star & Nakshatra Tithi November 2, 2024 05:58 AM to 06:35 AM, Nov 03 Anuradha, Vishakha Dwitiya November 4, 2024 06:35 AM to 08:04 AM Anuradha Tritiya November 7, 2024 12:34 AM to 06:38 AM, Nov 08 Uttara Ashadha Saptami November 8, 2024 06:38 AM to 12:03 PM Uttara Ashadha Saptami November 13, 2024 01:01 PM to 03:11 AM, Nov 14 Revati Trayodashi November 16, 2024 07:28 PM to 06:45 AM, Nov 17 Rohini Pratipada, Dwitiya November 18, 2024 06:46 AM to 03:49 PM Mrigashirsha Tritiya November 25, 2024 06:52 AM to 01:24 AM, Nov 26 Uttara Phalguni Dashami Griha Pravesh Muhurat dates in December In December 2024, there are auspicious Griha Pravesh Muhurat dates that are considered favorable for initiating significant events related to one’s home. Here’s a breakdown of the auspicious timings along with their celestial alignments:December 5: The Muhurat time is from 12:49 PM to 05:26 PM. This period coincides with the Uttara Ashadha Nakshatra and Panchami Tithi, which are believed to be favorable for starting new endeavors related to your home. December 11: The Muhurat time is from 07:04 AM to 11:48 AM. During this time, the Revati

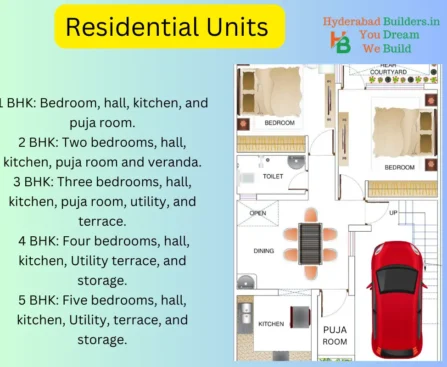

What is Bhk full form? BHK full form is “Bedroom Hall Kitchen.” It is a standard classification system used in real estate to denote the number of bedrooms in a residential property, along with the presence of a hall (living room) and kitchen. The number preceding “BHK” indicates the total count of bedrooms in the property. What is 1bhk means in India A 1 BHK (1 Bedroom Hall Kitchen) is a type of residential unit commonly found in apartment buildings or housing complexes. It is designed to accommodate a single bedroom, a combined living room and dining area (referred to as the hall or living room), and a kitchen A standard 1 bhk consists of 1 Bedroom: The bedroom serves as a private sanctuary for relaxation and sleep. It typically encompasses an area ranging from 120 to 180 square feet, providing ample space for a bed, wardrobe, and other essential furniture. 1 Hall (Living Room): The hall, or living room, is a common area for socialization, relaxation, and entertainment. With an area ranging from 180 to 250 square feet, it accommodates seating arrangements, entertainment units, and other furnishings. 1 Kitchen: The kitchen is a dedicated space for food preparation and cooking. It typically ranges from 70 to 100 square feet, offering sufficient room for countertops, cabinets, appliances, and meal preparation activities. 1 Bathroom: The bathroom is an essential part of the unit, providing facilities for personal hygiene. It usually spans from 40 to 60 square feet, accommodating fixtures such as a toilet, sink, and shower or bathtub. 1 Dining Area: The dining area provides space for consuming meals. With an area ranging from 40 to 60 square feet, it allows for the placement of a dining table and chairs, facilitating comfortable dining experiences. the terminology used to describe residential units can sometimes be confusing. From 1 BHK to 5 BHK, each designation signifies a specific layout and configuration tailored to different housing needs. Let’s delve into the details of these configurations to gain a better understanding of what each entails. Difference between 1 bhk, 2 bhk, 3 bhk, 4 bhk, 5 bhk in India every , understanding the configurations of residential units is crucial for both buyers and builders. From 1 BHK to 5 BHK, each unit offers distinct features tailored to accommodate varying lifestyle needs. Let’s delve into the specifics of what each configuration typically includes, with a focus on additional amenities like puja room, varanda, balcony, storage space, commonly found in Indian homes. What is 1bhk full form? 1 BHK (1 Bedroom Hall Kitchen): A 1 BHK unit comprises one bedroom, one hall (also known as a living room), and a kitchen. Typically suited for individuals or couples, it offers a compact yet functional living space. Additionally, a 1 BHK often includes a puja room, providing residents with a dedicated space for religious rituals. What is 2bhk means? 2 BHK (2 Bedroom Hall Kitchen): In contrast, a 2 BHK unit offers two bedrooms along with 1 hall and kitchen. This configuration is well-suited for small families or individuals seeking additional space for guests or home office setups. Additionally, a 2 BHK may feature a veranda, providing residents with an outdoor space for relaxation or socializing. What is 3bhk Means? 3 BHK (3 Bedroom Hall Kitchen): With three bedrooms, a hall, and a kitchen, a 3 BHK unit caters to larger families or individuals desiring ample living space. Apart from the standard amenities, a 3 BHK often includes utility areas and terrace access, offering residents added convenience and outdoor living options. What is 4bhk means? 4 BHK (4 Bedroom Hall Kitchen): A 4 BHK unit provides even more space, featuring four bedrooms, a hall, and a kitchen. This configuration is ideal for larger families or individuals seeking extra rooms for various purposes, such as a home office, study room, or guest bedroom. Additionally, a 4 BHK often comes with storage space, ensuring residents have sufficient room for their belongings. What is 5bhk means? 5 BHK (5 Bedroom Hall Kitchen): At the pinnacle of residential configurations, a 5 BHK unit offers five bedrooms, a hall, and a kitchen. This layout caters to extended families or individuals with specific lifestyle requirements, providing ample space for customization and personalization. Along with standard amenities, a 5 BHK may include multiple toilets for added convenience. Residential Unit of 1bhk, 2 bhk, 3 bhk, 4 bhk and 5 bhk Residential Unit Bedrooms Kitchen Hall Puja Room Veranda Utility Area Terrace Storage Space Toilets 1 BHK 1 1 1 Yes No No No No 1 2 BHK 2 1 1 Yes Yes Yes No No 2 3 BHK 3 1 1 Yes Yes Yes Yes No 3 4 BHK 4 1 1 Yes Yes Yes Yes Yes 4 5 BHK 5 1 1 Yes Yes Yes Yes Yes 5 Standard size of 1 bhk, 2 bhk, 3 bhk, 4 bhk, 5 bhk Residential Unit Minimum built up Area Required (sqft) Construction Cost per sqft (₹) Total Construction Cost (₹) 1 BHK 450 – 600 sq ft 1625 – 1800 ₹731,250 – ₹1,080,000 2 BHK 800 – 1000 sq ft 1625 – 1800 ₹1,300,000 – ₹1,800,000 3 BHK 1800 – 2300 sq ft 1800 – 2300 ₹3,240,000 – ₹5,290,000 4 BHK 2200 – 3000 sq ft 1800 – 2300 ₹3,960,000 – ₹6,900,000 5 BHK 3000 – 4000 sq ft 1800 – 2300 ₹5,400,000 – ₹9,200,000 In addition to the layout and amenities, the construction cost per square foot varies depending on factors such as location, quality of construction materials, and labor charges. The cost of construction building materials, including cement, steel, bricks, and fittings, also contributes to the overall expenses. Understanding these cost factors is essential for planning and budgeting residential projects effectively. Why people apt for 0.5, 1.5, or 2.5 BHK units? People opt for 0.5, 1.5, or 2.5 BHK units for several reasons, including: Affordability: These configurations often provide a more budget-friendly option compared to larger units like 2 BHK or 3 BHK apartments. They allow individuals or small families to enjoy the benefits of additional space

Weather your constructing a new house or considering upgrading your ceiling with a false ceiling but unsure about the costs involved? Look no further! In this detailed guide, we break down everything you need to know about what is the cost to install false ceiling, from materials to design considerations and even additional electrical work. Whether you’re aiming for a budget-friendly option or a luxurious finish, we’ve got you covered. What is False ceiling? A false ceiling, also known as a dropped ceiling or suspended ceiling, is a secondary ceiling installed below the original or true ceiling of a room. It is typically constructed using lightweight materials such as gypsum, POP, or metal framing, which are suspended from the original ceiling structure. What are the primary purposes to install false ceiling ? Concealment: False ceilings are used to hide unsightly elements such as electrical wiring, air conditioning ducts, and plumbing pipes. By concealing these elements, the false ceiling creates a cleaner and more aesthetically pleasing look in the room. Sound Insulation: False ceilings can improve sound insulation by reducing the transmission of sound between rooms or floors. The space between the original ceiling and the false ceiling can be filled with sound-absorbing materials, such as mineral wool, to dampen noise and improve acoustics. Aesthetic Enhancement: False ceilings offer a versatile platform for incorporating various design elements, such as recessed lighting, decorative moldings, and architectural details. They allow for creative expression and customization, enhancing the overall visual appeal of the space. Types of False ceiling POP False Ceiling:POP (Plaster of Paris) false ceilings are a common choice for many Indian homes due to their affordability, fire resistance, and versatility in design. POP is a quick-setting plaster made of white powder that can be easily molded into various shapes and designs. It is known for its ability to conceal electrical wiring and provide a seamless look to the ceiling. The cost of a POP false ceiling typically ranges from ₹95 to ₹105 per square foot, plus an additional 18% GST. This makes POP false ceilings one of the preferred options for homeowners looking to enhance the aesthetics of their interiors without breaking the bank. Gypsum False Ceiling:Gypsum false ceilings are another popular option known for their fire resistance and cost-effectiveness. Gypsum boards are readily available in standard sizes and are used in conjunction with Gyproc boards and local A-grade channels to create false ceilings. While standard gypsum false ceilings, with Gyproc board and local A-grade channels, are priced at ₹75 to ₹85 per square foot, premium gypsum options, featuring premium Gyproc boards and channels, may cost between ₹90 to ₹105 per square foot, both prices excluding an additional 18% GST. It’s worth noting that gypsum false ceilings tend to be bulkier compared to other materials and are more suitable for rooms with higher ceilings. Laminate and Veneer False Ceilings:For homeowners seeking the aesthetic appeal of wood without the maintenance concerns, laminate and veneer false ceilings are viable alternatives. Laminate false ceilings offer a wood-like appearance and are available in various finishes. They are priced at ₹700 to ₹800 per square foot, excluding an additional 18% GST. On the other hand, veneer false ceilings provide a luxurious look with genuine wood veneer, which may require additional polishing. Veneer false ceilings typically cost between ₹900 to ₹1,200 per square foot, plus an additional 18% GST. While laminate false ceilings are more budget-friendly compared to veneer, both options offer durability and aesthetic appeal. PVC False Ceiling:PVC false ceilings are preferred in areas prone to moisture, such as bathrooms and balconies, due to their moisture resistance. PVC false ceilings are also available in a variety of textures, including a wood-like finish, making them a cost-effective alternative to real wood. The cost of a laminate PVC ceiling ranges from ₹160 to ₹185 per square foot, excluding an additional 18% GST. Despite their affordability and moisture resistance, PVC false ceilings lack the fire resistance of materials like POP and gypsum. Cost to install false ceiling per sqft The price of a false ceiling varies greatly depending on the material chosen. We outline the costs per square foot for different materials, including: POP (Plaster of Paris) Standard and Premium Gypsum Laminate and Veneer PVC Material Price Range (per Sq. Ft.) Notes POP ceiling ₹95 to ₹105 + 18% GST take longer than Gypsum Standard gypsum ₹75 to ₹85 + 18% GST For gypsum false ceiling with Gyproc board and local A-grade channels Premium gypsum ₹90 to ₹105 + 18% GST For gypsum false ceiling with premium Gyproc board and channels Laminate false ceiling ₹700 to ₹800 + 18% GST Cost may vary depending on laminate finishing Veneer false ceiling ₹900 to ₹1,200 + 18% GST Cost may vary depending on veneer base price and polish type (PU or melamine) PVC false ceiling ₹160 to ₹185 + 18% GST For laminate PVC ceiling *The prices mentioned above are estimates based on the scope of work. Actual prices may vary depending on factors such as city, labour charges, material and finish, design complexity, and the size of your home. How to choose False Ceiling Material Each false ceiling material offers unique qualities that cater to different needs and preferences. POP and gypsum false ceilings are both fire-resistant and budget-friendly, making them suitable for various applications. Laminate false ceilings provide the appearance of wood without the maintenance requirements, while veneer false ceilings offer a luxurious look with genuine wood veneer. PVC false ceilings are moisture-resistant and budget-friendly, making them ideal for areas exposed to moisture. Homeowners should consider factors such as fire resistance, budget, water resistance, and malleability when choosing the right false ceiling material for their space. Material Fire-resistant Budget-friendly Water-resistant Malleable POP Yes Yes No Yes Gypsum Yes Yes No No Laminate No No No No Veneer No No No No PVC No Yes Yes No How to Calculate false ceiling Calculate Surface Area: Measure the length and width of your ceiling in feet. Multiply these two dimensions to

In this article we are going to cover what is plastering? Types of plastering and Gypsum vs Cement plaster What is Plastering? Plastering is a construction technique used to create a smooth, even, and durable finish on walls, ceilings, and other surfaces. It involves the application of a thin layer of plaster material onto a substrate, typically made of masonry, concrete, or wood. Plastering serves several purposes, including: Surface Preparation: Before plastering, the substrate is prepared by ensuring it is clean, free of dust, and properly primed. Any cracks or imperfections may be repaired or filled to create a smooth base for the plaster. Application of Plaster: Plaster is mixed with water to form a workable paste, which is then applied to the prepared surface using various techniques such as troweling, spraying, or throwing. The plaster is spread evenly and smoothed out to achieve the desired finish. Creating a Smooth Finish: The plaster is worked and smoothed to eliminate any bumps, ridges, or imperfections. Depending on the desired result, multiple layers of plaster may be applied and smoothed out to achieve a flawless surface. Decoration: Plastering can also involve decorative elements such as ornamental moldings, textures, or patterns. These decorative features can enhance the aesthetic appeal of the surface and add architectural interest to a space. Protection and Durability: Plastering provides a protective coating that helps to shield the underlying structure from moisture, weathering, and wear and tear. It adds strength and durability to walls and ceilings, prolonging their lifespan. Insulation and Soundproofing: Some types of plaster contain insulating materials or additives that improve thermal and sound insulation properties, enhancing the comfort and acoustics of a building. Types of Plastering In Construction Cement Plastering: Cement plastering involves the application of a mixture of cement, sand, and water to the surfaces of walls or ceilings. It provides a durable and strong finish, suitable for both interior and exterior surfaces. Cement plastering is commonly used in construction for its versatility and resistance to weathering. Gypsum Plastering: Gypsum plastering, also known as plaster of Paris (POP), involves the application of gypsum-based plaster to surfaces. It provides a smooth and fine finish, making it ideal for interior walls and decorative purposes. Gypsum plastering offers excellent fire resistance and is easy to work with due to its fast setting time. Lime Plastering: Lime plastering utilizes lime as the primary binding material mixed with sand and water. It provides a breathable finish suitable for historic or heritage buildings, allowing moisture to escape from the walls. Lime plastering offers flexibility and can be used on various substrates, including masonry, cob, and timber. Clay Plastering: Clay plastering involves the application of clay-based plaster on walls or ceilings. It provides a natural and breathable finish, suitable for eco-friendly and sustainable construction. Clay plastering regulates indoor humidity, absorbs odors, and offers thermal insulation properties. Exterior Plastering: Exterior plastering, also known as rendering, involves applying a protective layer of plaster on the exterior surfaces of buildings. It helps to waterproof and weatherproof the structure while enhancing its appearance. Exterior plastering can be done using cement-based, lime-based, or acrylic-based materials, depending on the requirements and climate conditions. Roughcast Plastering: Roughcast plastering is a textured finish applied to exterior walls to provide a rustic appearance. It involves throwing or spraying a mixture of cement, sand, and small stones onto the surface, followed by a trowel finish. Roughcast plastering offers good durability and weather resistance, making it suitable for traditional and contemporary architectural styles. Gypsum vs Cement plaster Parameter Gypsum Plaster Cement Plaster Water Curing No need to have curing for gypsum Must for 4 days Setting Time 4 hours 36 hours Ready for Primer 72 hours 360 hours Surface Finish Putty Finish Rough Finish Compressive Load Strength 98,400 N 72,400 N Density 1,333 kg/cu.m 2,222 kg/cu.m Fire Heat Sound Insulation Yes No Raw Material Gypsum powder commonly with hardeners Cement + sand (Site mixed) · Cement + sand (Packaged) Additional Materials Alkali sulfate, alum, borax N/A Color Pure white Grey Factory-made gypsum plaster is factory made No Curing Air curing for 24 hours and ready to paint after 72 hours Wet curing for 7 days and drying plaster for at least 3 days Application Areas Internal Internal and External Minimum Thickness 6 mm 10 mm Final Finish Smooth Rough Ease of Use Very easy Not so easy Per Square Feet Cost High Low Recyclable Yes No Thermal Conductivity Low High Fire Resistance High Low Rust Inhibitor Yes No Sustainability Yes No Environmental Impact Low High Installation Time Short Long Standard Packaging Size 25 kg 40 kg Compressive Strength 3.5 to 7.5 MPa (depending on ratio) 5 – 7 MPa Cost Per 100 Sq ft Rs. 2,300/- Rs. 2000 to 2600/- Additional Punning for Smooth Surface Rs. 2,300 May require POP Punning (6-8 mm) on it Finish Smooth finish and Ready to receive paint Depend on quality of sand Cost of Gypsum Plaster and Cement plaster Per sq ft Cost of Gypsum plastering in India is ₹23 per sq ft Square Footage Gypsum Plaster Cost (Rs.) Cement Plaster Cost Range (Rs.) 100 Sq ft Rs. 2,300/- Rs. 2000 to 2600/- 200 Sq ft Rs. 4,600/- Rs. 4000 to 5200/- 300 Sq ft Rs. 6,900/- Rs. 6000 to 7800/- 400 Sq ft Rs. 9,200/- Rs. 8000 to 10400/- 500 Sq ft Rs. 11,500/- Rs. 10000 to 13000/- 1000 Sq ft Rs. 23,000/- Rs. 20000 to 26000/- Wall Plaster labor Cost with material cost Description Rate Per sq.ft 1000 sq.ft 2000 sq.ft 3000 sq.ft 4000 sq.ft 5000 sq.ft Wall Plaster Labor cost Rs.23-25/- Rs.25,000 Rs.50,000 Rs.75,000 Rs.1,00,000 Rs.1,25,000 plastering Material Cost (M-Sand, Cement) Rs.30-35/- Rs.35,000 Rs.70,000 Rs.1,05,000 Rs.1,40,000 Rs.1,75,000 Total Cost of Wall Plaster with material Rs.55-60/- Rs.60,000* Rs.1,20,000* Rs.1,80,000* Rs.2,40,000* Rs.3,00,000* Plastering Surfaces and walls: Brick or Block Walls with Rough and Solid Surfaces: These surfaces provide mechanical adhesion for the plaster. Mechanical keys are formed when wet undercoat plaster dries, creating a bond between the plaster and the surface. Plaster keys help limit