How to check Cement bag before purchasing Cement is a crucial construction material, vital for creating concrete and mortar used in RCC framed structures. Its binding properties allow it to mix well with aggregates, forming a strong, homogeneous mixture. However, the quality of cement directly impacts the strength and durability of a structure. Unfortunately, adulteration in cement is common, and laypeople often lack awareness about important considerations when purchasing and storing cement. Hyderabad builders offers valuable insights on this matter. What to Check Before Buying Cement? Given the high cost of cement and its significant impact on overall project expenses, it’s essential to ensure you’re buying authentic, high-quality cement. Adulterated or inferior cement can compromise the longevity of a structure. To avoid such risks, there are specific standard specifications you should check on a cement bag before purchase: Step-by-Step Guide for How to check cement bag Step 1: Verify Manufacturer’s Details Check the cement bag for the manufacturer’s name and registered trademark.Ensure that the printing is clear and without spelling errors to avoid counterfeit products. Step 2: Look for the ISI Mark Ensure the ISI mark is printed in black on the cement bag.This mark indicates compliance with the required specifications. Step 3: Assess Cement Grade and Type Identify the grade and type of cement (e.g., Ordinary Portland Cement, 53 Grade).This information should be clearly printed on the bag. Step 4: Confirm Net Weight Check the listed net weight (e.g., 25 Kg, 50 Kg) on the cement bag.Accurate weight listing is a sign of standard quality. Step 5: Evaluate the Brand Choose a well-known, reputable brand.Review any available technical details or cut-sheets provided by the brand. Step 6: Check MRP Verify the Maximum Retail Price (MRP) printed on the bag.This helps to avoid being overcharged and prevents fraud. Step 7: Ensure ‘Use No Hooks’ Warning Look for the phrase ‘Use no Hooks’ or an equivalent symbol.This is an indication of proper handling guidelines. Step 8: Inspect Batch Number Find the batch/control unit number indicating the week, month, and year of packing.Preferably, use cement that is packed recently (less than 3 months old). Step 9: Note Manufacturer’s Address The address should be mentioned on the bag for any future enquiries. Step 10: Check for Performance Improvers If any performance improvers are added, their type and percentage should be listed. Step 11: Confirm IS Code Number Ensure the correct IS code is printed for the type of cement you are buying (e.g., “IS-12269-1987” for OPC 53 grade). Storing Cement Bags After purchasing, it’s crucial to store cement bags properly to maintain their quality. Hyderabad builders has published an article with tips and tricks for effective on-site storage of cement bags. Proper storage ensures the longevity and effectiveness of the cement, thereby contributing to the durability and strength of your construction project. Why is it important to check a cement bag before purchasing? Checking a cement bag before purchasing is crucial because the quality of cement directly impacts the strength and durability of a structure. It also helps in identifying counterfeit or adulterated cement, which can compromise the longevity of the structure. What should I look for in a cement bag’s manufacturer details? Verify the manufacturer’s name and registered trademark on the cement bag. Make sure the printing is clear and free from spelling mistakes to avoid counterfeit products. What does the ISI mark on a cement bag signify? The ISI mark, which should be printed in black, indicates that the cement complies with the required specifications and quality standards. How do I assess the cement grade and type? Check the bag for the grade and type of cement, such as “Ordinary Portland Cement, 53 Grade.” This information should be clearly printed on the bag. Why is confirming the net weight of the cement bag important? Confirming the net weight (e.g., 25 Kg, 50 Kg) ensures that you are getting the correct quantity, and it’s a sign of standard quality control. How does the brand of cement affect my purchase? Choosing a well-known, reputable brand is important. Review any technical details or cut-sheets provided by the brand to assess quality. How does the brand of cement affect my purchase? Choosing a well-known, reputable brand is important. Review any technical details or cut-sheets provided by the brand to assess quality. Where should I check regarding the MRP on a cement bag? Verify the Maximum Retail Price (MRP) printed on the bag to avoid being overcharged and to prevent fraud. What is the significance of the ‘Use No Hooks’ warning on a cement bag? The ‘Use No Hooks’ phrase or an equivalent symbol indicates proper handling guidelines to prevent damage to the bag and its contents. Why is inspecting the batch number important? The batch number indicates the week, month, and year of packing. Using cement that is packed recently (usually less than 3 months old) is advisable for better quality. How is the manufacturer’s address on the cement bag useful? The manufacturer’s address is important for any future enquiries or in case of issues with the cement quality. What are performance improvers in cement, and why should I check for them? Performance improvers, if added, enhance certain properties of the cement. If present, their type and percentage should be listed on the bag. How do I confirm the IS code number on a cement bag? Ensure the correct IS code (e.g., “IS-12269-1987” for OPC 53 grade) is printed on the cement bag, indicating it meets specific standards. How should I store cement bags after purchasing? Store cement bags in a dry, moisture-free area. Avoid direct contact with the ground and walls. Proper storage maintains the cement’s quality and ensures its effectiveness for your construction project.

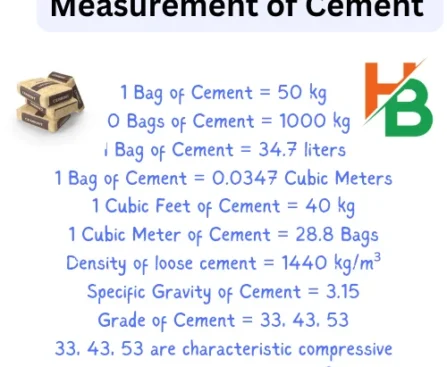

Measurements of cement Cement is the cornerstone of any construction project, a binding agent that gives structures their strength and durability. In the practice of civil engineering, understanding the properties and measurements of cement is not just academic—it’s a practical necessity. Let’s explore the ten fundamental points about cement that every civil engineer should know. 1. The Standard Measurement Unit: The Bag A typical bag of cement is the quintessential unit, weighing in at 50 kilograms. This standardization simplifies the calculation of how much cement is required for a project. 2. Bulk Handling: The Metric Ton When scaling up, it becomes necessary to think in terms of metric tons. Twenty bags make up a ton, equating to 1000 kilograms, providing a bulk measure that’s essential for large-scale constructions. 3. Volume Considerations Each bag of cement, when poured, would occupy a volume of 34.7 liters. Understanding the volume is crucial when it comes to storage and transportation logistics. 4. Cubic Meter Conversions In civil engineering, the cubic meter is a key unit of measure. A bag of cement translates to 0.0347 cubic meters, a conversion that is indispensable when dealing with concrete mix designs. 5. Weight-to-Volume Ratio Considering the weight, one cubic foot of cement equals 40 kilograms. This ratio is particularly useful in countries where the imperial system is still in use. 6. Cement Bags per Cubic Meter When preparing to mix concrete, it’s important to know that 28.8 bags of cement are needed to fill one cubic meter of volume. 7. Loose Cement Density The density of loose cement is 1440 kg/m³. This density is significantly different from that of compacted cement and can affect the mix and structural calculations. 8. Specific Gravity With a specific gravity of 3.15, cement is denser than water. This property is used to compare the density of cement to that of water, which can influence the curing time and the hydration process. 9. Cement Grades The strength of cement is designated by its grade—33, 43, or 53. These grades refer to the compressive strength measured in N/mm², indicating the force that cement can withstand after 28 days of setting. 10. Characteristic Compressive Strength Lastly, the characteristic compressive strength is denoted by the same numbers—33, 43, and 53 N/mm². These figures are paramount when choosing the right cement for structural integrity. Relate article: concrete strength and test procedure, How Ready mix concrete(rmc) is made? What is the weight of 1 cemnet bag The 50-kilogram bag is a universally accepted standard that facilitates easy calculation and handling across the construction industry. How does the metric ton relate to construction planning? Thinking in metric tons allows for efficient bulk ordering and planning, essential for large-scale construction projects. Why is understanding the volume of cement important? Knowing the volume a bag of cement occupies is crucial for logistical planning, including storage and transportation. What is the significance of the cubic meter in concrete mix designs? The cubic meter is a fundamental unit for mix designs, enabling accurate proportioning of cement to other concrete component How does the weight-to-volume ratio affect construction in imperial-system countries? The weight-to-volume ratio provides a necessary conversion for countries that use the imperial system, ensuring accurate measurements. How many bags of cement are required for one cubic meter of concrete Approximately 28.8 bags of 50 kg cement are needed to fill one cubic meter, which is crucial for precise concrete mixing. Why is the density of loose cement important in mix design? The density affects the volume-to-weight ratio, influencing the final mix proportions and the structural calculations What does the specific gravity of cement tell us? Specific gravity indicates how the density of cement compares to water, affecting hydration and curing times in concrete. What do the different cement grades mean? Cement grades like 33, 43, and 53 represent the compressive strength in N/mm², helping select the appropriate cement for various construction needs. How does characteristic compressive strength guide cement selection? It determines the load the cement can withstand after a set curing period, essential for ensuring structural integrity.

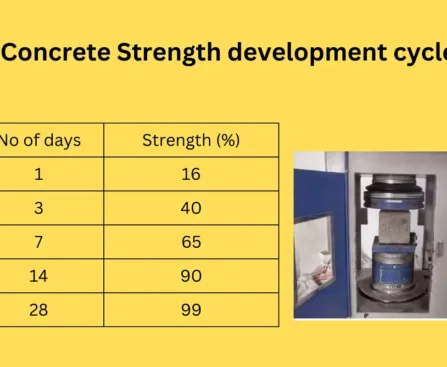

In-Depth Guide to Concrete Strength & Testing Procedure Concrete’s compressive strength is a vital indicator of its overall structural integrity and durability. This guide provides a step-by-step overview of the testing process, from preparation to execution. What is Compressive Strength? why is it important? Definition Compressive strength is defined as the capability of a material, like concrete, to withstand axial loads without undergoing failure or collapse. It’s a crucial measure of the structural integrity and durability of the material under compression. Importance: Concrete’s strength hinges on various factors: the individual compressive strength of cement, sand, and aggregate; material quality; mix proportions; water-cement ratio; curing methods; and temperature. Each element plays a crucial role in determining the final strength and durability of the concrete used in construction Structural Reliability: The compressive concrete strength indicates its ability to carry substantial loads, which is fundamental in ensuring the safety and stability of buildings and other structures. Quality Indicator: This metric serves as a key indicator of the quality of concrete. High compressive strength often correlates with good quality concrete that has been properly mixed and cured. Design and Engineering Decisions: Engineers and architects rely on compressive strength values to make informed decisions about the type of concrete to use in different parts of a structure, depending on the load-bearing requirements. Regulatory Compliance: Adherence to specified compressive strength values is often mandated in building codes and regulations, ensuring that structures meet safety standards. What is ASTMc39/c39m test? The American Society for Testing and Materials (ASTM) C39/C39M standard is a widely recognized guideline for the compressive strength testing of cylindrical concrete specimens. This standard is essential for ensuring consistency and reliability in testing methods across various construction projects. Concrete Compressive Strength Testing Process Step 1: Preparation of Test Specimens Selection of Cube Size: Common sizes are 15cm x 15cm x 15cm or 10cm x 10cm x 10cm, based on aggregate size. Mixing Concrete: Ensure a homogeneous mixture of cement, aggregate, and water. Mold Filling: Fill molds in layers, approximately 5 cm thick. Compact each layer with at least 35 strokes using a tamping rod. Ensure no air voids remain in the mix. Curing: After 24 hours, demold the specimens. Submerge them in water for a specified curing period (usually 7 or 28 days). Step 2: Setting Up the Testing Machine Calibration: Ensure the compression testing machine is calibrated. Positioning Specimen: Place the specimen centrally on the lower platen. Step 3: Applying the Load Loading Rate: Apply the load gradually at a rate of 140 kg/cm² per minute. Observation: Monitor the specimen for any signs of failure. Step 4: Determining the Compressive Strength Failure Point: Note the load at which the specimen fails (maximum load). compressive concrete strength Formula: Calculate the compressive strength using the formula: Compressive Strength =(Maximum Load / Cross-Sectional Area) Step 5: Result Interpretation and Reporting Record Keeping: Document the maximum load, specimen dimensions, and any anomalies during testing. Average Strength: Calculate the average strength from multiple specimens. Quality Assessment: Compare the results against the expected strength values for the concrete’s grade. Factors Influencing Compressive Strength Test Outcomes 1. Specimen Size and Shape Impact on Strength: The size and shape of a concrete specimen significantly influence the test results. Smaller specimens tend to show higher strength due to reduced likelihood of flaws and heterogeneities. Standardization: ASTM standards specify dimensions to ensure consistency. Deviations can lead to inaccurate strength assessments. 2. Mix Proportions and Quality Material Quality: The quality of cement, aggregate, and water, and their proportions, directly affect the concrete’s compressive strength. Mix Homogeneity: Uniform mixing of concrete components ensures consistent quality and strength throughout the specimen. 3. Curing Conditions Temperature and Humidity: Ideal curing conditions (like controlled temperature and humidity) are crucial for strength development in concrete. Duration: The length of the curing period impacts the hydration process, affecting the final compressive concrete strength. Insufficient curing can lead to weaker concrete. 4. Test Machine Accuracy Calibration: Regular calibration of the compression testing machine is essential for accurate force application and measurement. Load Application Rate: The rate at which load is applied as per ASTM standards influences the failure pattern and strength measurement. Inconsistent application rates can skew results. Compressive Concrete Strength Development of 1, 3, 7 ,14, 28 days No of days Strength (%) 1 16 3 40 7 65 14 90 28 99 Conclusion Compressive concrete strength testing is a crucial process in the construction sector, providing key insights into the quality and suitability of concrete for various applications. This step-by-step guide aims to facilitate a clear understanding of the procedure, ensuring accurate and reliable results. What is compressive strength in concrete, and why is it important? Compressive strength is the ability of concrete to withstand axial loads without failing. It’s crucial because it assesses structural integrity and durability, ensuring the safety and stability of buildings and structures. What is the ASTM C39/C39M test, and why is it significant? ASTM C39/C39M is a standardized test method for compressive strength testing of cylindrical concrete specimens. It’s important for ensuring consistent and reliable testing procedures across construction projects, enhancing quality control. What factors influence the compressive strength of concrete? Factors include cement quality, aggregate properties, water-cement ratio, mix proportions, curing conditions, and temperature. Each plays a vital role in determining concrete strength. What are the standard sizes for concrete test specimens, and how are they selected? Common sizes are 15cm x 15cm x 15cm or 10cm x 10cm x 10cm, chosen based on aggregate size and project requirements. Can you explain the process of mixing concrete for test specimens? Mix concrete components (cement, aggregate, water) thoroughly to ensure uniformity. Fill molds in layers, compacting each layer to remove air voids. After 24 hours, demold and cure the specimens. What is the significance of curing concrete specimens, and how is it done? Curing is vital for hydration and strength development. Submerge specimens in water for a specified curing period (usually 7 or 28 days) to maintain optimal conditions. How do you calibrate

Introduction The backbone of modern construction, Thermo-Mechanically Treated (TMT) bars, are crucial for the structural integrity of buildings. Among these, Fe 415, Fe 500, and Fe 550D grades are widely recognized for their distinctive properties and applications. This article delves into these specific grades, highlighting their characteristics, manufacturing processes, and suitability for various construction projects. Why is steel is used in concrete Concrete, by its nature, has high compressive strength but low tensile strength. This means it can withstand loads that tend to compress it but would crack under loads that tend to stretch or bend it. To compensate for this weakness, steel reinforcement bars (rebar), which have high tensile strength, are added to the concrete at the locations where the tensile stresses are anticipated to be the highest. When concrete is poured around steel rebars, it forms a solid bond with the steel as it cures. This bond is critical to ensure that the two materials act together under load. The steel bars carry the tensile forces while the concrete carries the compressive forces. The result is a homogeneous structural material that can withstand a variety of stresses and loads, making it ideal for a wide range of construction applications, including beams, floors, bridges, and foundations. What is TMT Bars: A Brief Overview TMT bars are a result of a unique metallurgical process called thermo-mechanical treatment. This process imparts superior strength, ductility, and weldability to the steel, making it ideal for reinforcing concrete in construction projects. They come in various grades, which signify the yield strength, ductility, and tensile strength of the bars. These grades are standardized and each has specific characteristics that make them suitable for different types of construction requirements. Common grades of TMT bars include: Fe 415: This is a common grade used for residential buildings because of its excellent bendability. Fe 500: A higher strength variant than Fe 415, providing a balance between strength and ductility. Fe 550: This grade has even higher tensile strength and is used for structures that require additional strength. Fe 600: This is used for heavy-duty structures like bridges and industrial buildings. Fe 500D: The ‘D’ here signifies higher ductility. This grade is particularly used in areas prone to earthquakes due to its high ductility and tensile strength. Fe 550D: Similar to Fe 500D but with higher yield strength. Fe 415 TMT Bars: Properties and Applications Fe 415 bars, known for their excellent ductility and higher elongation, are the preferred choice in earthquake-prone areas. With a yield strength of 415 N/mm², they offer a perfect blend of strength and flexibility, reducing the risk of structural failure during seismic activities. These bars are typically used in residential buildings, low-rise structures, and projects where bending and re-bending of bars are required. Fe 500 TMT Bars: A Balance of Strength and Flexibility Fe 500 grade bars, with a yield strength of 500 N/mm², strike a balance between strength and flexibility. They are stronger than Fe 415 bars, making them suitable for multi-storey buildings, bridges, and industrial structures. Despite their high strength, they maintain adequate ductility, which is essential for supporting dynamic loads. Fe 550D TMT Bars: The High-Strength Alternative Fe 550D grade bars represent the high-strength segment of TMT bars with a yield strength of 550 N/mm². They are designed for heavy-duty construction projects such as high-rise buildings, long-span bridges, and industrial structures requiring a robust framework. The ‘D’ in Fe 550D denotes enhanced ductility, making these bars a reliable choice for projects demanding high load-bearing capacity. Manufacturing Process: A Key Differentiator The manufacturing process of TMT bars involves rapid quenching of hot steel bars, followed by air cooling. This process forms a hardened surface layer while maintaining a softer core, thereby giving the bars their unique strength and ductility. The variations in temperature and cooling rates in the manufacturing process lead to the different grades of TMT bars. Chemical Composition and Mechanical Properties of fe415, fe 500 and fe 550d Each grade of TMT bar has a specific chemical composition and set of mechanical properties. Fe 415 typically contains a lower carbon content compared to Fe 500 and Fe 550D, which contributes to its higher elongation and ductility. Fe 500 and Fe 550D, with slightly higher carbon content, offer greater strength but with controlled proportions of sulphur and phosphorus to ensure ductility. Applications in Construction Fe 415: Ideal for residential and commercial buildings in seismic zones.Fe 500: Suitable for multi-storey buildings and industrial applications.Fe 550D: Best for heavy-duty infrastructure projects and high-rise constructions. Difference between Fe500 vs Fe550 D Property / Grade Fe 500 TMT Grade Bar Fe 550D TMT Grade Bar Tensile Strength Exceeds 545.0 N/mm² Exceeds 585.0 N/mm² Chemical Composition Iron, Carbon (0.3%), Sulphur (0.055%), Phosphorus (0.055%) by mass, S+P ≈ 0.105% Iron, Carbon (0.25%), Sulphur (0.04%), Phosphorus (0.04%) by mass, S+P ≈ 0.07% Yield Strength (fy) 500 N/mm² 550 N/mm² Ultimate Tensile Strength (fu) 545 N/mm² 585 N/mm² Elongation 12 16 TS/YS Ratio 1.09 1.08 Applications Multi-storey and commercial buildings, private ventures, earthquake-resistant structures Large-scale construction projects, mechanical undertakings, scaffolds, high-weight-bearing structures, underground and marine projects 8. Concluding Thoughts Choosing the right grade of TMT bar is pivotal for the safety, durability, and longevity of any construction project. Fe 415, Fe 500, and Fe 550D each serve unique purposes and are selected based on the structural demands and environmental considerations of the project. Understanding these grades helps architects, engineers, and builders make informed decisions, ensuring the structural integrity and sustainability of modern constructions.

Luxurious Living in Kokapet: A Guide to Villas in Hyderabad’s Prized Suburb Kokapet, A Suburban Paradise Nestled in the heart of Hyderabad, India, lies Kokapet, a suburban oasis known for its opulent villas that redefine luxury living. This thriving neighborhood boasts an array of attractions, making it the perfect choice for those with discerning tastes in real estate. In this guide, we’ll delve into the allure of Kokapet and explore the factors that make it a sought-after destination for homeowners who crave the best in life. Why Villas in Kokapet Kokapet’s Strategic Location Kokapet enjoys a prime location, strategically situated near the city’s Outer Ring Road (ORR). This location provides impeccable connectivity to Hyderabad’s key areas and business districts. For professionals working in IT hubs like Gachibowli and the Financial District, Kokapet offers an ideal residence. Additionally, easy access to the Rajiv Gandhi International Airport ensures that the world is just a flight away. Kokapet’s picturesque landscapes and serene surroundings create a tranquil haven amidst the urban buzz. The Marvels of Villa Architecture The villas in Kokapet stand as architectural marvels, boasting exceptional designs that blend modern aesthetics with functional spaces. Whether you appreciate contemporary or traditional styles, these villas cater to diverse preferences. With meticulous attention to detail, high-quality materials, and innovative designs, Kokapet villas redefine opulence in every sense. Features That Define Kokapet Villas Kokapet villas are celebrated for their luxurious features, setting new standards in upscale living. These residences offer a plethora of amenities, from private swimming pools and landscaped gardens to spacious balconies and high-end fittings. Smart home automation systems and dedicated parking spaces are just the beginning. Step inside, and you’ll find interiors that exude elegance, with spacious living areas, gourmet kitchens, lavish bathrooms, and stylish finishes. Secure and Vibrant Gated Communities One of Kokapet’s hallmarks is its gated communities, providing residents with a secure and vibrant lifestyle. Equipped with 24/7 security systems, surveillance cameras, and controlled access points, these communities prioritize the safety and well-being of their residents. But they offer more than security; clubhouses, gyms, sports facilities, and landscaped parks promote a holistic and vibrant lifestyle. Green Bliss Kokapet’s green spaces and recreational facilities enchant residents and visitors alike. Villas are surrounded by flourishing greenery, beautifully designed gardens, and breathtaking vistas, creating a rejuvenating and tranquil atmosphere. Whether you enjoy leisurely walks, outdoor activities, or simply unwinding amidst nature’s beauty, Kokapet has it all. Some gated communities even offer exclusive recreational facilities like swimming pools, jogging tracks, children’s play areas, and outdoor sports facilities, ensuring a healthy and active lifestyle for residents. Proximity to Renowned Educational Institutions Kokapet’s strategic positioning extends to its proximity to renowned educational institutions. Families with children find it an ideal choice, as quality schools and colleges are just a stone’s throw away. Say goodbye to long commutes and hello to excellent educational facilities that nurture young minds. The Convenience of Kokapet Kokapet’s connectivity and infrastructure are second to none. With seamless access to major roads, highways, and public transportation networks, residents can easily explore other parts of Hyderabad. The neighborhood also boasts shopping malls, supermarkets, healthcare facilities, and entertainment centers, enhancing residents’ convenience and comfort. Real Estate on the Rise Kokapet’s real estate sector is booming, making it an attractive investment destination. The high demand for villas, coupled with its strategic location and upscale amenities, contributes to the appreciation of property values. Furthermore, proactive measures by local authorities to enhance infrastructure and promote sustainable development amplify the real estate investment potential in the area. Investors can expect promising returns on their investments in Kokapet’s villas Recent auction in Kokapet The Hyderabad Metropolitan Development Authority (HMDA) generating over 3300 crores by selling 45-acre lands in Kokapet suggests strong demand for real estate in this region the high bid making 100cr per acre in kokapet. This could be due to various factors, including its strategic location, proximity to IT hubs, infrastructure development, and the growth potential of the area.. Villa Specifications and Amenities Luxury Tailored to Your Needs Kokapet’s villas come in various configurations and sizes, ranging from spacious 3BHK to luxurious 5BHK villas. These residences are designed to provide ample space, natural light, and ventilation. The specifications include well-planned layouts, large bedrooms, modular kitchens, premium flooring, and high-quality fittings and fixtures. Elegance and Functionality The architects behind Kokapet’s villas pay special attention to kitchens, including modern appliances, abundant storage space, and elegant finishes. The bathrooms are equally luxurious, featuring premium sanitaryware, fixtures, and fittings that guarantee a lavish bathing experience. Aesthetics and Durability Kokapet’s villas employ high-quality materials like vitrified tiles, marble, or wooden flooring, chosen to complement each villa’s design and theme. The finishes are of superior quality, showcasing a perfect blend of aesthetics and durability. Safety and Luxury Combined Safety is paramount in Kokapet’s villas. Advanced security systems, including CCTV surveillance, an intercom facility, and round-the-clock security personnel, ensure residents’ peace of mind. Moreover, the gated communities offer a range of amenities such as swimming pools, gymnasiums, multipurpose halls, landscaped gardens, and children’s play areas, promising a luxurious and enjoyable lifestyle. About Kokapet A Glimpse into Kokapet Kokapet is a rapidly developing suburb located on the outskirts of Hyderabad. It falls under the Gandipet mandal of Ranga Reddy district. The locality has emerged as a prominent IT and business hub, with plans for about 65 million square feet of office space in the coming years. Alongside office towers, the area also boasts many high-rise residential towers. Kokapet is renowned for its high-end luxury villas, serene surroundings, and green landscapes. It strikes the perfect balance between urban conveniences and natural beauty, making it an attractive destination for homeowners seeking a peaceful and luxurious living experience. Kokapet is also witnessing rapid infrastructural growth, with developments in roads, utilities, and social amenities. Conclusion Kokapet’s Luxurious Villas In summary, villas in Kokapet offer a luxurious and refined living experience in a serene and well-connected location. With strategic advantages, architectural excellence, and luxurious features, Kokapet stands out as an attractive destination