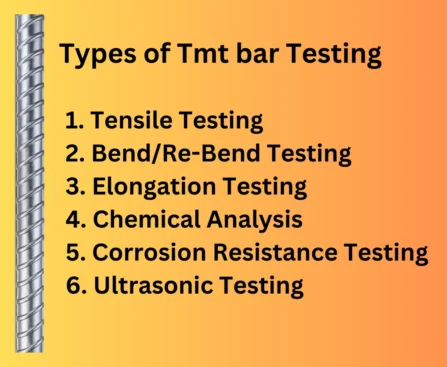

Types of Tmt bar testing TMT Bar Testing After Manufacturing The manufacturing of Thermo Mechanically Treated (TMT) bars involves intricate processes aimed at enhancing their strength, durability, and overall performance. However, the journey of a TMT bar doesn’t end with production; rigorous testing is a crucial step to ensure the bars meet stringent quality standards. TMT bar testing refers to the various examinations and assessments conducted on Thermo-Mechanically Treated (TMT) bars after their manufacturing process. These tests are crucial to ensuring the quality, strength, and reliability of TMT bars, which are widely used in construction for their enhanced properties. Let’s delve into the essential TMT bar testing procedures conducted after manufacturing to guarantee superior quality. Understanding the significance of different types of TMT bar testing is crucial for ensuring the quality and durability of construction materials. Types of TMT Bar Testing 1. Tensile Testing2. Bend/Re-Bend Testing3. Elongation Testing4. Chemical Analysis5. Corrosion Resistance Testing6. Ultrasonic Testing Now explore each of the types of TMT bar testing in more detail to understand their role in guaranteeing superior quality Tensile Testing: Tensile testing is a fundamental mechanical analysis conducted to determine the tensile strength of TMT bars. This critical property is indicative of the material’s ability to withstand axial loads and stretching forces. Using a sophisticated Universal Testing Machine (UTM), a TMT bar undergoes incremental tensile stress until it reaches its breaking point. The resulting stress-strain curve offers insights into the mechanical behavior, ultimate strength, and elongation characteristics of the material. ASTM tensile testing Bend/Re-Bend Testing: Bend/re-bend testing is essential to evaluate the ductility and flexibility of TMT bars. The process involves subjecting a TMT bar to bending stress, simulating real-world construction scenarios. It ensures that the bar can undergo bending without developing surface cracks or defects. Additionally, the re-bend test assesses the material’s ability to regain its original shape after deformation, crucial for applications where flexibility is essential without compromising strength. Elongation Testing: Elongation testing provides a deeper understanding of the material’s ductile behavior under tensile stress. It quantifies the percentage increase in the length of a TMT bar before fracture, highlighting its ability to deform plastically without immediate failure. Higher elongation values signify superior ductility, enabling the TMT bar to absorb energy and undergo deformation without compromising its structural integrity. Chemical Analysis: Chemical analysis is a meticulous examination of the elemental composition of TMT bars. Utilizing advanced spectrometry, this process precisely identifies and quantifies elements such as Carbon, Phosphorus, Copper, Manganese, Chromium, and Sulphur. Strict adherence to specified chemical composition standards ensures the TMT bars meet the required metallurgical properties, corrosion resistance, and overall durability. Corrosion Resistance Testing: Corrosion resistance testing involves subjecting TMT bars to harsh environmental conditions or accelerated corrosion simulations. This rigorous evaluation assesses the material’s ability to withstand corrosion, a critical factor for longevity in diverse applications. TMT bars with robust corrosion resistance properties offer enhanced durability, making them suitable for challenging construction environments. Ultrasonic Testing: Ultrasonic testing is a non-destructive technique used to scrutinize the internal structure of TMT bars. Employing ultrasonic waves, this method identifies internal defects, voids, or irregularities that may compromise the structural integrity of the bar. Through detailed ultrasonic inspection, manufacturers ensure that TMT bars are free from hidden flaws, contributing to their overall reliability and performance in construction projects. Benefits of different types of tmt bar test: When discussing the benefits of TMT bar testing, emphasize the importance of considering the diverse insights provided by the types of TMT bar testing. For example, “The combined results of Tensile Testing, Bend/Re-Bend Testing, and other TMT bar testing offer a comprehensive understanding Tensile Strength of TMT Bar in Hyderabad, India: The tensile strength of TMT bars can vary based on factors such as the grade of the TMT bar and the specific manufacturer. To obtain the accurate tensile strength of TMT bars in Hyderabad, India, you should refer to the product specifications provided by reputable TMT bar manufacturers or suppliers in the region. Manufacturers often provide this information to help customers make informed decisions about the suitability of TMT bars for their construction projects. Many leading TMT bar manufacturers maintain in-house testing laboratories to ensure the quality of their products. These facilities are equipped with advanced testing equipment for conducting essential tests like tensile testing, bend/re-bend testing, elongation testing, chemical analysis, corrosion resistance testing, and ultrasonic testing. The in-house testing process enables manufacturers to closely monitor the quality of their TMT bars, ensuring they meet industry standards and comply with safety regulations. This commitment to rigorous quality control contributes to the manufacturers’ reputation and builds confidence among builders and engineers who rely on TMT bars for construction projects What are the types of tmt bar testing? 1. Tensile Testing2. Bend/Re-Bend Testing3. Elongation Testing4. Chemical Analysis5. Corrosion Resistance Testing6. Ultrasonic Testing Why is Bend/Re-Bend Testing important for TMT bars? Bend/Re-Bend testing evaluates the ductility and flexibility of TMT bars, ensuring they can undergo bending without developing surface cracks. It is vital for applications requiring flexibility without compromising strength What is Tensile Testing for TMT bars? Tensile testing is a crucial mechanical analysis that measures the ability of TMT bars to withstand axial loads and stretching forces. It provides insights into the material’s strength and elongation characteristics What does Elongation Testing reveal about TMT bars? Elongation testing assesses the ability of TMT bars to elongate under stress. It quantifies the percentage increase in length before fracture, indicating the material’s ductility and its capacity to absorb energy without breaking Why is Chemical Analysis performed on TMT bars? Chemical analysis examines the elemental composition of TMT bars. It ensures adherence to specified chemical composition standards, confirming the required metallurgical properties, corrosion resistance, and overall durability. What is the significance of Corrosion Resistance Testing for TMT bars? Corrosion resistance testing evaluates how well TMT bars can withstand corrosion, a critical factor for longevity in diverse applications. Bars with robust corrosion resistance offer enhanced durability in challenging construction environments. How does Ultrasonic Testing contribute to TMT bar quality? Ultrasonic

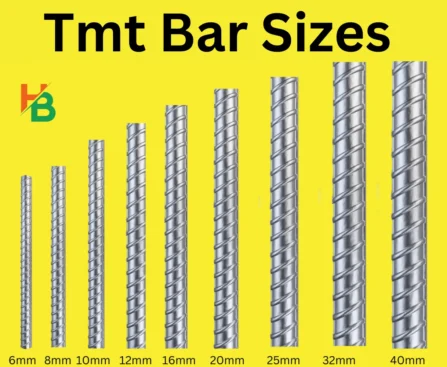

Decoding TMT Bar Sizes chart In India In the intricate world of construction, the choice of building materials holds the key to creating structures that stand strong against the test of time. Thermo-Mechanically Treated (TMT) bars, known for their strength and durability, come in a variety of sizes. From the slender 6mm to the robust 40mm, each TMT bar size serves a specific purpose in the construction of buildings and infrastructure. Let’s unravel the significance of different TMT bar sizes in construction. 6mm and 8mm TMT Bars: Characteristics: Smaller diameter for flexibility and ease of handling. Ideal for light construction work. Applications: Residential projects benefit from these bars in constructing slabs, balconies, and other non-load-bearing structures. Their smaller size makes them suitable for intricate construction needs, ensuring precision in smaller-scale projects. 10mm and 12mm TMT Bars: Characteristics: Increased diameter for improved load-bearing capacity. Versatile and suitable for small to medium-sized construction projects. Applications: Commonly used in residential buildings for creating beams, columns, and load-bearing structures. Offer a balance between strength and flexibility, making them integral in various structural elements. 16mm and 20mm TMT Bars: Characteristics: Stepping into heavier construction requirements. Enhanced strength for load-bearing components. Applications: Employed in the construction of mid-sized buildings and structures. Used for crucial load-bearing elements like columns and beams, providing the necessary strength and durability. 25mm and 32mm TMT Bars: Characteristics: Larger diameter for robustness. Ideal for high-rise buildings and infrastructure projects. Applications: Staple in the construction of tall structures, providing the necessary strength to withstand heavy loads. Ensures structural stability in larger and more complex projects. 40mm TMT Bars: Characteristics: Reserved for projects demanding the utmost strength. Used in critical load-bearing elements of massive structures. Applications: Essential in projects like bridges, industrial buildings, and high-rise complexes. Ensures structural integrity and durability in large-scale constructions where strength is paramount. TMT Bar Sizes and Applications TMT Bar Sizes Applications 6mm and 8mm Light construction work, residential projects for slabs, balconies, and non-load-bearing structures. 10mm and 12mm Small to medium-sized construction projects, residential buildings for beams, columns, and load-bearing structures. 16mm and 20mm Mid-sized buildings and structures, load-bearing elements like columns and beams. 25mm and 32mm High-rise buildings, infrastructure projects, ensuring structural stability in larger and complex projects. 40mm Projects demanding utmost strength, critical load-bearing elements of massive structures like bridges and industrial buildings. As construction practices evolve, the strategic selection of TMT bar sizes will continue to play a vital role in crafting structures that endure and excel in diverse urban landscapes Choosing the Right TMT Bar Sizes: Considerations for Builders Selecting the appropriate TMT bar size is a crucial decision that builders and engineers need to make based on the specific demands of a construction project. Here are key considerations: Structural Design: Follow the structural design specifications provided by architects and engineers. The design will dictate the sizes required for different structural elements. Load-Bearing Requirements: Assess the load-bearing capacity needed for different parts of the structure. Larger diameter TMT bars are suitable for components bearing heavier loads. Building Codes and Standards: Adhere to local building codes and standards that prescribe the minimum requirements for TMT bar sizes in construction projects. Project Scale: Consider the scale and purpose of the construction project. Residential projects may require smaller sizes, while large-scale infrastructure projects demand larger diameters. TMT bar Weight chart TMT Bar Sizes and Applications Conclusion In the realm of construction, the spectrum of TMT bar sizes offers a versatile toolkit for builders to craft structures that endure and excel. As construction practices evolve, the strategic selection of TMT bar sizes will remain pivotal in ensuring the resilience and longevity of diverse structures across urban landscapes. For builders and construction professionals, mastering the art of choosing the right TMT bar size is akin to unlocking the full potential of a construction project, ensuring it stands tall, strong, and steadfast against the forces of time and nature. What are TMT Bars? TMT bars, or Thermo-Mechanically Treated bars, are steel bars widely used in construction for their strength and durability. The manufacturing process involves heat treatment to create a tough outer core and a softer inner core What Sizes Do TMT Bars Come In? TMT bars come in various sizes, ranging from 6mm, 8mm, 10mm, 12mm, 16mm, 20mm, 25mm, 32mm,40mm in diameter. Each size serves a specific purpose in construction, from light residential projects to heavy infrastructure development. What is the Application of 6mm and 8mm TMT Bars? These smaller diameter TMT bars (6mm and 8mm) are ideal for light construction work. They find applications in residential projects for constructing slabs, balconies, and other non-load-bearing structures. How are 10mm and 12mm TMT Bars Used? Well-suited for small to medium-sized construction projects, 10mm and 12mm TMT bars are commonly used in residential buildings for creating beams, columns, and other load-bearing structures. What Projects Require 16mm and 20mm TMT Bars? Stepping into heavier construction requirements, 16mm and 20mm TMT bars are employed in the construction of mid-sized buildings and structures. They offer enhanced strength for load-bearing components like columns and beams. Where are 25mm and 32mm TMT Bars Applied? Larger diameter TMT bars (25mm and 32mm) are a staple in the construction of high-rise buildings and infrastructure projects. They provide the necessary robustness for withstanding heavy loads and ensuring structural stability. When are 40mm TMT Bars Used? Reserved for projects demanding the utmost strength, 40mm TMT bars are used in critical load-bearing elements of massive structures such as bridges, industrial buildings, and high-rise complexes. How to Choose the Right TMT Bar Size? Consider the structural design specifications provided by architects and engineers, assess the load-bearing requirements, adhere to local building codes and standards, and factor in the scale and purpose of the construction project. Why is Choosing the Right TMT Bar Size Crucial? The strategic selection of TMT bar sizes is pivotal in ensuring the resilience and longevity of diverse structures. It impacts the overall strength, stability, and load-bearing capacity of the constructed edifice. What Does the Future Hold for

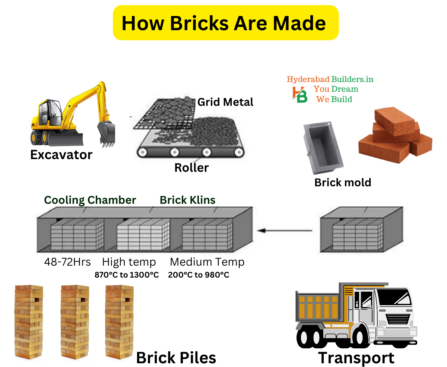

How Bricks are made The brick manufacturing industry, though rooted in timeless principles, has undergone transformative changes propelled by technological advancements. While the fundamentals remain unaltered, contemporary brick plants demonstrate increased efficiency and enhanced product quality. Lets dive in to the process how bricks are made and what raw material requires and and what is the step by step brick manufacturing process. the are different type of bricks each has its own manufacturing process the type of manufacturing we choose to manufacture will have effect on both price of bricks and on environment also. Today the brick price in Hyderabad,India is Rs 9.50 Inr/ piece for 1000 bricks price is around Rs 9,500 INR this is standard quality brick price As per Invest India and IBEF, the construction Industry in India is expected to become the 3rd largest construction market globally and to reach USD 1.4 trillion by 2025. Moreover, Real Estate Industry in India is expected to reach USD 1 trillion by 2030 and will contribute to around of% to India’s GDP Raw Materials required in Brick Manufacturing Clay as the Foundation: At the heart of brick manufacturing lies clay, an abundant and naturally occurring mineral on Earth. However, not all clays are interchangeable; they must meet specific criteria to be suitable for brick production. Key attributes include plasticity, the capacity to be shaped or molded when mixed with water, ample strength to retain form, and the ability to fuse at elevated temperatures. Categorizing Clay Varieties: Clays come in various forms, with three primary categories: surface clays, shales, and fire clays. Surface clays, found near the Earth’s exterior, may be upthrusts of older deposits or more recent sedimentary formations. Shales, subjected to high pressures, nearly harden into slate. Fire clays, mined at deeper levels, boast refractory qualities. Shale: Another essential raw material, shale contributes distinct properties to bricks. It is often blended with clay to achieve specific characteristics. Fire Clays: Fire clays are used in brick manufacturing for their ability to withstand high temperatures during firing. They are one of the categorized types of clays. Water: Water is crucial in the manufacturing process, especially during the preparation phase. It is added to clay to achieve plasticity and facilitate the forming process. Engobes (Clay Slurries): Finely ground clay or colorants in the form of engobes are applied to the brick surface during manufacturing to create textures, coatings, and distinctive patterns. Colorants: Various colorants, including iron for red hues, are naturally present in clays. The firing process and kiln control also influence the final color of the bricks. Concrete (for Concrete Bricks): In the case of concrete bricks, cement, aggregates, and other additives are used along with water to form the brick. Sand (for Sand-Lime Bricks): Sand is a key component in the production of sand-lime bricks, contributing to their composition and characteristics. Fly Ash (for Fly Ash Bricks): Fly ash, a waste product from coal combustion, is used in the manufacturing of fly ash bricks. Lubricants: Lubricants derived from processing organic materials are used in the forming process to prevent clay from sticking to molds. Sawdust (as Burnout Material): Sawdust is sometimes used as a burnout material in the firing process, contributing to the environmental efficiency of brick manufacturing How bricks are made? Clay Collection: Suitable clay is gathered from natural deposits or mines. It should have the right composition and texture. Weathering: The clay is left to weather, exposed to the elements, which helps improve its plasticity and workability. Preparation: The clay is mixed with water to form a workable consistency, sometimes adding sand or other materials for better strength. Molding: The clay is shaped into brick forms using molds. It can be done by hand or using machinery. Drying: The molded bricks are allowed to air-dry, reducing moisture content. Firing: Bricks are fired in kilns at high temperatures, ranging from 1,000 to 2,000 degrees Celsius, turning them into durable, solid units. Cooling: After firing, bricks are left to cool gradually, ensuring strength and durability. The final product, shaped and solidified, emerges as durable and versatile building blocks. In the late 19th century, contemporary U.S. brick production predominantly relies on mechanization. Step by step bricks manufacturing process Mining and Storage: Unearthing the Foundation The journey of brick creation commences with the extraction of surface clays, shales, and specialized fire clays from open pits, utilizing robust power equipment. These raw materials, brimming with potential, are then meticulously transported to designated storage areas within the manufacturing plant. The strategic storage not only ensures a continuous production flow, regardless of weather conditions but also facilitates blending, a crucial step for achieving uniformity, controlling color variations, and meeting specific brick body requirements. Preparation: Shaping the Raw Potential Before the alchemy of brick formation begins, large clay lumps and stones undergo a transformative size reduction. This critical preparation step involves the precise processing of materials through inclined vibrating screens, an intricate dance that regulates particle size. This meticulous preparation sets the stage for the subsequent phases of the manufacturing process. Forming the Brick: Crafting Excellence The heart of the manufacturing process beats within the forming phase, where clay transforms into the iconic brick shapes. Three primary processes govern this phase: Stiff-Mud Extravaganza: Approximately 90% of U.S. brick production unfolds through the stiff-mud process. Clay is extruded, de-aired in a vacuum chamber, and meticulously cut to precision. This intricate dance enhances workability, plasticity, and strength. Soft-Mud Elegance: Embracing clays with higher water content, the soft-mud process involves molding the clay in lubricated molds. The result? Exquisite brick forms, each a testament to the adaptability of the manufacturing process. Dry-Press Precision: Suited for low-plasticity clays, the dry-press process employs minimal water. Hydraulic or compressed air rams then press the clay into steel molds, showcasing precision and efficiency. Drying: From Wet to Solid Wet bricks, embodying 7 to 30 percent moisture contingent on the forming method, undergo a delicate drying phase. Within dedicated chambers, temperatures ranging from 100 ºF to 400 ºF guide the bricks through

Cement plastering, also known as rendering or stucco, is a common method used to cover and protect walls and ceilings. Here’s a general step-by-step process for doing cement plastering The process of cement plastering involves a strategic response to the increasing demand in the infrastructure and housing sectors. The Indian cement industry is on the brink of a substantial expansion, planning to add 145-160 million tonnes of capacity from FY25 to FY28. Construction Materials Used in Cement Plastering: Cement: The primary binding material . Sand: sand Provides bulk and workability to the plaster mix. Water: Necessary for the hydration process and achieving the right consistency. Fiber Mesh (Optional): Adds strength, especially in exterior plastering. Metallic Corner Beads: For sharp and durable edges in corners. Plastering Trowel: Essential for applying and smoothing plaster. Hawk (Plasterer’s Tool): A tool to hold and transport plaster. Spirit Level: Ensures an even and level surface. Sponge: Used for achieving textured finishes. Mixing Bucket: For combining and preparing the plaster mix. Bonding Agent (Optional): Enhances adhesion, especially on smooth surfaces. Safety Gear (Gloves, Goggles): Ensures safety during the plastering process. the cement plastering process into three distinct parts: Pre-Plastering, During Plastering, and Post-Plastering. Part 1: Pre-Plastering 1. Surface Preparation: Clean the surface thoroughly, removing any dust, dirt, or loose particles. If the surface is highly absorbent, dampen it with water to prevent rapid suction of water from the plaster mix. 2. Mixing the Plaster: In a mixing bucket, combine cement and sand in the desired ratio. A common mix is 1 part cement to 3 parts sand, but this can vary based on the project requirements. Gradually add water and mix until you achieve a smooth, lump-free consistency. The mix should be workable but not too thin. 3. Applying Bonding Agent (Optional): Apply a bonding agent if needed, especially on surfaces that are smooth or less porous. This enhances the adhesion of the plaster. Part 2: During Plastering 4. Applying the First Coat (Scratch Coat): Use a plastering trowel to apply the first coat, also known as the scratch coat, onto the surface. Apply the plaster in a thin, even layer, scratching the surface with the trowel to create a rough texture. This helps the next coat adhere better. 5. Applying the Second Coat (Brown Coat): Once the scratch coat has set but is still slightly damp, apply the second coat, known as the brown coat. Use a plastering trowel to achieve a smooth and even surface. Feather the edges to blend with the existing surface. 6. Smoothing and Leveling: Use a straight edge or spirit level to ensure an even and level surface. Correct any uneven areas by adding or removing plaster as needed. 7. Finishing Coat (White Coat or Finish Coat): Apply the finishing coat once the brown coat has set but is still damp. Achieve a smooth finish using the plastering trowel. For a textured finish, you can use a sponge or other tools. 8. Optional: Adding Fiber Mesh or Reinforcement: In some cases, especially for exterior plastering, adding fiber mesh to the mix or embedding it in the brown coat can enhance the plaster’s strength. Part 3: Post-Plastering 9. Curing: Allow the plaster to cure slowly. Keep the surface damp for a few days to prevent rapid drying, which can lead to cracks. 10. Final Inspection: Inspect the finished plaster for any defects or uneven areas. Touch up as necessary. 11. Optional: Install Metallic Corner Beads: If needed, install metallic corner beads for corners to ensure sharp and durable edges. 12. Cleaning Up: Clean your tools and dispose of any excess material properly. Always follow local building codes and guidelines, and consider consulting with a professional if you’re unsure about any specific requirements for your project. The steps outlined here are a general guide, and actual practices may vary based on the type of plaster and specific project requirements. Related questions How to prepare the surface for cement plastering? Clean the surface thoroughly, removing any dust, dirt, or loose particles. If the surface is highly absorbent, dampen it with water to prevent rapid suction of water from the plaster mix. What is the optimal ratio of cement to sand in the plaster mix? A common mix is 1 part cement to 3 parts sand, but ratios can vary based on project requirements. Gradually add water and mix until achieving a smooth, lump-free consistency. Why is a bonding agent recommended, and when should it be used? A bonding agent enhances adhesion, especially on smooth or less porous surfaces. It is applied before plastering to improve the bond between the substrate and plaster. What tools are essential for the cement plastering process? Essential tools include a plastering trowel, hawk (plasterer’s tool), spirit level, sponge, and mixing bucket. Safety gear such as gloves and goggles is also crucial. List of Materials used in Cement Plastering? List of Materials used in Cement plastering Cement Sand Water Fiber Mesh (Optional) Metallic Corner Beads Plastering Trowel Hawk (Plasterer’s Tool) Spirit Level Sponge Mixing Bucket Bonding Agent (Optional) Safety Gear (Gloves, Goggles) Is it necessary to add fiber mesh for exterior plastering? Adding fiber mesh to the mix or embedding it in the brown coat is optional but recommended for exterior plastering. It enhances the plaster’s strength and durability. How long should I allow the plaster to cure, and why is it important? Allow the plaster to cure slowly, keeping the surface damp for a few days. This prevents rapid drying, reducing the risk of cracks and ensuring a durable finish. What are the key safety measures during the cement plastering process? Wear safety gear, including gloves and goggles, to ensure protection. Follow proper lifting techniques, use tools safely, and adhere to all safety guidelines. Can metallic corner beads be used for all types of corners? Yes, metallic corner beads are suitable for all types of corners and are essential for ensuring sharp and durable edges. How can I achieve a textured finish with cement plaster? To achieve a textured finish,

Indian Cement Industry Growth The Indian cement industry is poised for a remarkable phase of expansion, with plans to add 145-160 million tonnes of capacity from FY25 to FY28. This move is a strategic response to the burgeoning demand from the infrastructure and housing sectors and marks a significant development in the industry’s growth trajectory. Capacity Expansion: A Response to Rising Demand In the last five fiscal years, the industry has seen an addition of 119 million tonnes per annum, culminating in a total capacity of 595 million tonnes. The forthcoming capacity augmentation is not just about meeting the escalating demand; it’s also a concerted effort to consolidate market share in a highly fragmented and competitive arena. Growth Trends and Regional Focus The cement industry has experienced impressive demand growth, with an 8% increase in FY22 and a 12% surge in FY23. The coming fiscal year is anticipated to witness the commissioning of 70-75 million tonnes of new capacity, with a significant focus on the eastern and central regions of India. This regional emphasis underscores the industry’s strategy to tap into area-specific demand dynamics. The Role of Major Players and Market Dynamics Large cement manufacturers are set to account for over half of the planned capacity addition. This trend underscores the robust financial health and strong market presence of these major players. However, the influx of incremental supply and heightened competition is expected to keep price growth in check, with predictions of a mere 0-1% increase, stabilizing Cement prices in India around Rs 390-395 per 50-kg bag. Fiscal Forecasts and Price Trends Looking ahead, the industry anticipates a demand growth of 10-12% this fiscal, propelled by government initiatives in affordable housing and infrastructure projects. The subsequent fiscal year might see a moderation in demand growth to 4-6%, with a potential uptick in cement price in Hyderabad Rs 400-405 per 50-kg bag. Insights from Industry Experts Industry analysts have highlighted key trends impacting the industry. An expert notes a 1% decrease in cement prices during the first three quarters of the current fiscal, marking a reversal after four years of growth. Bhatt points out the easing of power, fuel, and freight charges, which collectively account for half of the production cost, providing relief to manufacturers amid steady realizations. Conclusion: A Period of Robust Growth Amid Challenges The Indian cement industry is embarking on a period of significant growth, driven by solid demand and backed by the financial strength of its leading players. However, this growth comes with its own set of challenges, including price stabilization due to increased supply and intense market competition. As the industry navigates these dynamics, its ability to balance expansion with profitability will be crucial in shaping its future trajectory. What is driving the expansion of the Indian cement industry from FY25 to FY28? The expansion is a strategic response to the rising demand from the infrastructure and housing sectors, indicating a significant development in the industry’s growth trajectory. How much capacity has the Indian cement industry added in the last five fiscal years, and what is the total capacity now? In the last five fiscal years, the industry has added 119 million tonnes per annum, resulting in a total capacity of 595 million tonnes. What are the growth trends in the Indian cement industry, and which regions are being focused on for new capacity commissioning? The industry experienced an 8% growth in FY22 and a 12% surge in FY23. The focus for the coming fiscal year is on commissioning 70-75 million tonnes of new capacity, particularly in the eastern and central regions of India. What role do major players play in the Indian cement industry, and how will they impact cement prices? Major cement manufacturers are set to account for over half of the planned capacity addition. While this highlights their robust financial health, it is expected to keep price growth in check, with predictions of a mere 0-1% increase, stabilizing cement prices in India around Rs 390-395 per 50-kg bag. What are the fiscal forecasts and price trends for the Indian cement industry in the upcoming years? The industry anticipates a demand growth of 10-12% in the current fiscal, driven by government initiatives in affordable housing and infrastructure projects. The subsequent fiscal year might see a moderation in demand growth to 4-6%, with a potential uptick in cement prices in Hyderabad to Rs 400-405 per 50-kg bag.