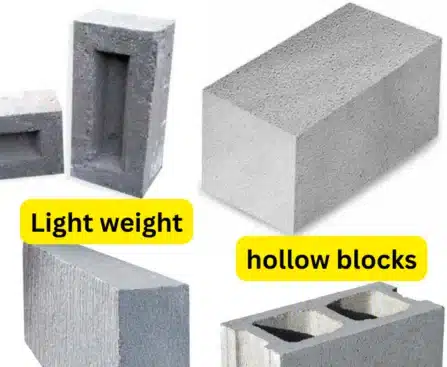

What are Concrete Blocks? As the name suggests, a concrete block is made of concrete, wherein the composition includes sand, cement, water, and gravel. These elements are staggered in layers, with cement in between, to create solid concrete walls. Concrete blocks come in various types, such as solid and hollow, each serving specific construction needs. It’s worth noting that different countries and regions have various names for these blocks. For instance, they are commonly known as cinder blocks in North America and breeze blocks in Britain. What are Solid Concrete Blocks: Solid concrete blocks, characterized by their heavyweight and robust nature, find applications in force-bearing walls. Larger than traditional bricks, they expedite the masonry process, making construction less time-consuming. Despite being labeled as ‘solid,’ they boast about 25 percent open holes, differentiating them from fully solid structures. advantages of Solid Concrete Blocks : Impressive compressive strength (5 – 8 Mpa), surpassing alternatives. Economical production at the site, eliminating transportation costs. Low water absorption, setting them apart in their class. Disadvantages of Solid Concrete Blocks: High density (2100 to 2200 kg/cum), contributing to a heavy dead load. Dimensional variations may be observed. Labor-intensive chiseling required for service installations. Solid Concrete Blocks Sizes: 400x200x200mm (15.75×7.87×7.87 inches), 400x200x150mm (15.75×7.87×5.91 inches), 400x200x100mm (15.75×7.87×3.94 inches) Used In: Low-rise construction projects Hollow Concrete Blocks: With more than 25 percent open holes, hollow concrete blocks, available in half and full sizes, streamline construction processes and reduce costs. Advantages of Hollow Concrete Blocks: Moderate compressive strength (5 – 8 Mpa). Lightweight nature (density = 1250 to 1400 kg/cum), minimizing dead loads. On-site manufacturing for cost-effective production. Disadvantages of Hollow Concrete Blocks: Services installation may require concrete filling post-chiseling. Potential wastage in the process. Hollow Concrete Blocks sizes: 400x200x200mm (15.75×7.87×7.87 inches), 400x200x150mm (15.75×7.87×5.91 inches), 400x200x100mm (15.75×7.87×3.94 inches) Used In: Low-rise construction projects Concrete Block Prices in India: In India, the price of a concrete block can range between Rs 30-50, depending on the size and type of block being purchased. It’s essential for buyers to consider these factors when planning construction projects, ensuring both quality and cost-effectiveness. Aerated Concrete Blocks: Aerated concrete blocks are characterized by their lightweight nature, making them an ideal choice for high-rise constructions. Here are the pros and cons: Pros: Lightweight (density = 600 – 700 kg/cum), easy to handle. Reduction in dead load on the structure optimizes reinforcement consumption. Chiselling for services (Electrical and Plumbing) installation is less labor-intensive and time-consuming. High dimension accuracy. Improved thermal and acoustic properties. Low plaster consumption. Cons: Compressive strength ranges from 3 – 5MPa. Requires careful handling to minimize breakages. Cannot be manufactured on-site. Unit cost is relatively high. Typical Sizes Available: 600x200x200mm (23.62×7.87×7.87 inches) 600x200x150mm (23.62×7.87×5.91 inches) 600x200x100mm (23.62×7.87×3.94 inches) Used In: High-rise construction Light weight Aerated Concrete Blocks: Aerated concrete blocks are characterized by their lightweight nature, making them an ideal choice for high-rise constructions. Advantages Light weight Aerated Concrete Blocks Lightweight (density = 600 – 700 kg/cum), easy to handle. Reduction in dead load on the structure optimizes reinforcement consumption. Chiselling for services (Electrical and Plumbing) installation is less labor-intensive and time-consuming. High dimension accuracy. Improved thermal and acoustic properties. Low plaster consumption. Disadvantages of Light weight Aerated Concrete Blocks: Compressive strength ranges from 3 – 5MPa. Requires careful handling to minimize breakages. Cannot be manufactured on-site. Unit cost is relatively high. Light weight Aerated Concrete Blocks Sizes: 600x200x200mm (23.62×7.87×7.87 inches), 600x200x150mm (23.62×7.87×5.91 inches), 600x200x100mm (23.62×7.87×3.94 inches) Used In: High-rise construction Cellular Lightweight Concrete Blocks: Cellular lightweight concrete blocks offer advantages suitable for high-rise construction. Pros: Lightweight (density = 550 to 650 kg/cum), reducing the dead load on the structure. High dimension accuracy. Chiselling for services (Electrical and Plumbing) installation is less labor-intensive and time-consuming. Enhanced thermal and acoustic properties. On-site manufacturing for economical production (no transportation, taxes). Low plaster consumption. Cons: Compressive strength ranges from 3 – 4MPa, relatively lower than some substitutes. Requires better quality control during production. Proper handling to prevent breakages. Typical Sizes Available: 600x200x200mm (23.62×7.87×7.87 inches), 600x200x150mm (23.62×7.87×5.91 inches), 600x200x100mm (23.62×7.87×3.94 inches) Best Use: High-rise construction Fly Ash Blocks: Fly ash blocks are suitable for low and mid-rise constructions. Pros: Compressive strength ranges from 3.5 – 5MPa. Can be manufactured on-site for economical production. Chiselling for services (Electrical and Plumbing) installation is less labor-intensive and time-consuming. Cons: High density (2100 to 2200 kg/cum). Dimensional variations observed. High plaster consumption. Typical Sizes Available: 600x200x200mm (23.62×7.87×7.87 inches), 600x200x150mm (23.62×7.87×5.91 inches), 600x200x100mm (23.62×7.87×3.94 inches)400x200x200mm (15.75×7.87×7.87 inches), 400x200x150mm (15.75×7.87×5.91 inches), 400x200x100mm (15.75×7.87×3.94 inches) Best Use: Low and mid-rise construction Types of solid blocks and hollow blocks Solid Concrete Blocks Hollow Concrete Blocks Fly Ash Blocks Concrete Stretcher Blocks Light Aerated Concrete Blocks Lintel Blocks Paving Concrete Blocks Partition Concrete Blocks Jamb Concrete Blocks Bullnose Concrete Blocks Cellular-Lightweight Concrete Blocks Concrete Corner Blocks

Why Telangana number plates for vehicles start with TG not Ts In a significant move, the Telangana cabinet, under Chief Minister Revanth Reddy, has decided to redefine the state’s identity by changing its official abbreviation from ‘TS’ to ‘TG.’ This shift aims to distance itself from alleged political alignments of the past and underscores a focus on national aspirations rather than party affiliations. Harmony in New Anthem of Telangana: ‘Jaya Jaya Ho Telangana’ Takes Center Stage Accompanying the change in abbreviation, Telangana will embrace a new state anthem, ‘Jaya Jaya Ho Telangana,’ composed by Andre Sri. This musical shift signals a departure from the current state anthem and represents a fresh cultural expression for the state. Alongside this, the symbolic mother goddess, Telangana Talli, will undergo a reimagination in appearance, reflecting the evolving spirit of the region. Symbolic Transformation: Redefining State Representation The cabinet, led by Chief Minister Revanth Reddy, has decided to redesign the state’s official symbol. This redesign aims to create a symbol that “reflects the people without any trace of monarchy,” signaling a departure from symbols associated with the previous regime. The visual transformation aligns with the broader shifts in the state’s identity and governance. Caste Census Initiative: Telangana Aligns with National Commitment In line with the Congress’s promise to conduct a caste census across the nation, the Telangana government has decided to undertake this demographic survey within the state. This initiative underscores a commitment to understanding and addressing the diverse social fabric, making Telangana one of the early states to embark on this significant national commitment. Infrastructure Boost: New High Court Complex in Rajendranagar Ahead of the budget session, the Telangana cabinet has allocated 100 acres for a new high court complex in Rajendranagar district. This move emphasizes the government’s commitment to a robust judicial system and sets the stage for enhanced legal infrastructure, catering to the evolving needs of the state. Fulfilling Promises: Gas and Power Guarantees in Budget Session Chief Minister Revanth Reddy is poised to fulfill promises made during the election campaign by announcing gas and power guarantees during the upcoming budget session. This commitment aligns with the government’s broader goal of delivering on all six election guarantees within the initial 100 days of assuming power, showcasing a dedication to swift and impactful governance. Debating Development: Chief Minister Challenges Predecessor on Irrigation Projects In a bold move, Chief Minister Revanth Reddy has challenged his predecessor K Chandrashekar Rao (KCR), along with his son KT Rama Rao (KTR) and nephew Harish Rao, to a debate on irrigation projects. This challenge, accepted by Bharat Rashtra Samithi (BRS), sets the stage for a significant discourse on the state’s development priorities and the way forward for Telangana.

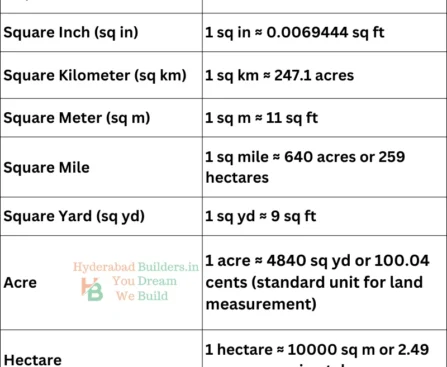

Land measurement units in India come in a diverse array, reflecting the country’s rich cultural and regional variations. Whether you are navigating the real estate market, planning agricultural ventures, or simply curious about land dimensions, understanding these units is crucial. Here’s a comprehensive guide to the common land measurement units and the art of converting them. How Land is Measured in India In India, land measurement is a diverse process involving various standard units depending on the size and nature of the land. Small Tracts or Residential Plots: Square Feet (sq ft): This unit is commonly used for measuring small plots or residential areas. 1 sq ft is approximately 0.0929 square meters. Square Metres (sq m): Similar to square feet, square meters are used for smaller land areas. 1 sq m is equivalent to 10.764 square feet. Large Tracts, Industrial, or Agricultural Land: Acres: This unit is prevalent for measuring large expanses of land, especially in the context of agriculture or industrial use. 1 acre is about 4,047 square meters or 0.4047 hectares. Hectares: Widely used globally and in specific contexts in India, 1 hectare equals 10,000 square meters. Regional Units in Villages: Bigha: A traditional unit with variations across states. The size of 1 Bigha can vary, with different regions having different conversion factors. Guntha: Commonly used in Maharashtra and Gujarat, 1 Guntha is about 1,089 square feet. Ground: Used in Karnataka, the size of 1 Ground can vary but is often around 2,400 square feet. Gaj: Typically used in North India, 1 Gaj is equivalent to 9 square feet. These regional units like Bigha, Guntha, Ground, and Gaj have historical and cultural significance, making them prevalent, especially in rural areas where traditional methods persist. Buyers and sellers often prefer using these units to measure land, reflecting a connection to local customs and practices. These regional units like Bigha, Guntha, Ground, and Gaj have historical and cultural significance, making them prevalent, especially in rural areas where traditional methods persist. Buyers and sellers often prefer using these units to measure land, reflecting a connection to local customs and practices. Understanding these units is crucial for anyone involved in real estate transactions in India, ensuring accurate measurements and facilitating smooth transactions, especially in regions where traditional units are prevalent. Plot vs. Ground: A “plot” is a designated piece of land, often for specific purposes like construction. “Ground” is a broader term for any land area, developed or not. Plot vs. Site: While “plot” refers to a specific land area, “site” is a broader term encompassing locations or areas, not necessarily demarcated for a specific purpose. Land vs. Ground: “Land” is a general term for the Earth’s surface. “Ground” is a specific piece of land, often used in a property context, indicating a localized area. Common land measurement units in India Land Measurement Unit Equivalent in Square Feet (sq ft) Square Feet (sq ft) 1 sq ft = 1 sq ft Square Centimeters (sq cm) 1 sq cm ≈ 0.00107639 sq ft Square Inch (sq in) 1 sq in ≈ 0.0069444 sq ft Square Kilometer (sq km) 1 sq km ≈ 247.1 acres Square Meter (sq m) 1 sq m ≈ 11 sq ft Square Mile 1 sq mile ≈ 640 acres or 259 hectares Square Yard (sq yd) 1 sq yd ≈ 9 sq ft Acre 1 acre ≈ 4840 sq yd or 100.04 cents (standard unit for land measurement) Hectare 1 hectare ≈ 10000 sq m or 2.49 acres approximately Bigha 1 Bigha ≈ 1,012 sq m Biswa 1 Biswa ≈ 151.25 sq yd Killa 1 Killa ≈ 4,047 sq m Kanal 1 Kanal ≈ 5,445 sq ft or 605 sq yd Chatak 1 Chatak = 180 sq ft Kattha 1 Kattha = 545 sq ft standard land area units Hectare: Commonly used for measuring forest or agricultural lands. Utilized in estate evaluation and town planning. Acres: Popularly used in the United States of America and the United Kingdom. Also used in India, particularly for measuring large areas like estates or farmland. Bigha: Commonly used in Indian States such as Punjab, Bihar, Uttar Pradesh, Haryana, Himachal Pradesh, Uttarakhand, Rajasthan, and Gujarat. No standard size; measurement units vary by state. Example: In Uttarakhand, one Bigha is 756.222 sq yd, while in West Bengal, it equals 1,600 sq yd. Square Foot: Widely used worldwide, an imperial and US customary unit of area. Commonly used in the US and partially in Canada. Ground: Commonly used in the southern State of Tamil Nadu. One ground is equivalent to 203 sq m or 24,000 sq ft. Square Meter: Standard International (SI) unit of area measurement. Denoted as sq m or m2. Katha: Popularly used in the eastern states of India. No standard size; varies by region. Example: In West Bengal, one katha equals 720 sq ft, while in Bihar, it is 1,361.25 sq ft. The most common land measurement units are square feet, acres and hectares. Here is an example that showcases measuring and converting land into widely used measurement units. Converting Biswa to Acres Biswa is commonly used as a land measurement unit in Delhi, Jammu and Kashmir, Rajasthan, Haryana and Himachal Pradesh. Below is the process to convert a land measured in Biswa into acres for standardization: For easier calculation, you may use 99acres area converter. However, in manual conversion, 1 Biswas is 0.03099 acres. Suppose the land area is 75,000 units of land in Biswa, which needs to be converted into acres; you can multiply it by 0.03099. 75,000 Biswa units of land x 0.03099 = 2,324.25 acres Converting sq ft to gaj The most commonly used term for real estate land measurements in India is sq ft. However, in many parts of North India, people prefer the measurements in gaj for better understanding. Here is the formula to convert area from sq ft to sq gaj: Converting Acres to Square Meters: Conversion Factor: 1 acre ≈ 4046.86 square meters. Example Calculation: If the land area is 5 acres, the conversion

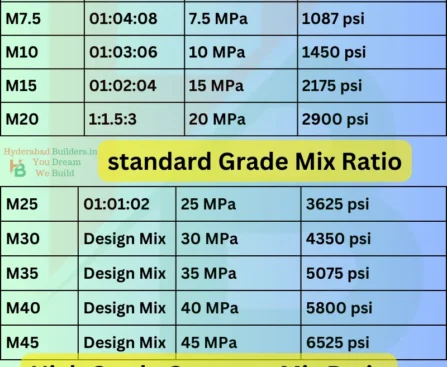

Explore Concrete Mix ratio, Grades of Concrete and their Comprehensive Strength (PSI) Introduction: Concrete, a fundamental construction building material, has played a pivotal role in construction for centuries. Composed of a mixture of cement, water, aggregates, and sometimes additives, concrete is renowned for its versatility, durability, and strength. This article explores the diverse world of concrete, from its composition to various types, applications, and strength ranges. What are Concrete Grades? Concrete grades are classifications that indicate the compressive strength of concrete at 28 days, as defined by the Bureau of Indian Standards (BIS). These grades are denoted by the prefix “M,” representing mix, followed by a number indicating the concrete’s strength in megapascals (MPa). The mix ratio of concrete components, such as cement, sand, and aggregates, contributes to its overall strength. Different grades cater to specific construction needs, with higher grades suitable for structures requiring superior strength, like dams and bridges What Grades of Concrete: Concrete is graded into three types 1) Ordinary grade concrete2) Standard Concrete3) High Grade Concrete Ordinary grade concrete Ordinary Grade of Concrete includes M10, M15, and M20, characterized by a lower compressive strength ranging from 1,450 to 3,200 PSI. These grades are suitable for non-structural construction purposes, such as patio slabs, pathways, and residential flooring, where exceptionally high strength is not a primary requirement. They strike a balance between workability and strength, making them versatile for various applications in construction. M10 (Compressive Strength: 1,450 PSI; Mix Ratio: 1:3:6 – Cement: Sand: Aggregates): Applications: Non-structural purposes where high strength is not a primary concern. Suitable for projects like patio slabs and pathways. Ideal for smaller construction projects where the load-bearing capacity is not a critical factor. Cost-effective choice for basic construction needs where structural integrity is not a priority. M15 (Compressive Strength: 2,175 PSI): Applications: Well-suited for applications requiring a balance of strength and workability. Ideal for sealing floors due to its moderate strength. Construction of roads, where a good combination of strength and durability is necessary. Versatile for various projects that demand a moderate level of compressive strength without excessive requirements. M20 (Compressive Strength: 2,900 PSI): Applications: Widely used in residential projects for various applications. Suitable for flooring, garages, and sheds in typical household constructions. Offers adequate strength to meet the demands of common residential needs. Provides a cost-effective solution for structures where high strength is not a critical factor. Standard Concrete Standard Grade of Concrete encompasses M25 to M45 grades, exhibiting enhanced compressive strength. These grades find application in constructing critical structures like concrete girders, slurry pits, high-tensile beams, and loading bays. With strengths ranging from 3,625 to 5,800 PSI, they offer durability and consistency, making them ideal for projects requiring robust internal and external support in construction. M25 (Compressive Strength: 3,625 PSI): Applications: Versatile grade for foundational structures providing internal support. Suitable for constructing various foundational elements in construction projects. Balances strength and workability, making it a versatile choice. M30 (Compressive Strength: 4,350 PSI):Applications: Highly durable and useful for roads facing harsh weather conditions and heavy vehicles. Suitable for areas with significant wear and tear, requiring a resilient concrete mix. M35 (Compressive Strength: 5,075 PSI):Applications: High consistency makes it suitable for constructing external walls of commercial buildings. Offers uniformity and strength for commercial construction projects. M40 (Compressive Strength: 5,800 PSI):Applications: Possesses high strength, suitable for holding heavy structures like beams. Anti-corrosive properties make it ideal for constructing septic tanks holding potent chemicals. High Grade Concrete High-Grade Concrete, spanning PSI strength from 6,525 to 9,425, comprises grades M45 to M65. Renowned for exceptional strength and durability, these grades are employed in constructing high-end structures like dams and bridges. With their robust composition, they ensure the integrity and longevity of critical constructions, meeting stringent requirements for heavyweight infrastructure projects. M45 (Compressive Strength: 6,525 PSI): Applications: Ideal for constructing substantial structures such as dams and factories.Impressive strength ensures integrity in critical constructions.M50 (Compressive Strength: 7,250 PSI): Applications:Designed mix for applications requiring a significant compressive strength.Suitable for projects demanding high strength and durability.M55 (Compressive Strength: 7,975 PSI): Applications: Designed mix for construction projects needing superior strength.Ideal for structures that face heavy loads and challenging conditions.M60 (Compressive Strength: 8,700 PSI): Applications: Designed mix with exceptional strength for specialized construction projects.Suitable for structures where extreme strength and durability are paramount.M65 (Compressive Strength: 9,425 PSI): Applications: Designed mix for critical constructions like bridges and high-end buildings.Impressive strength for structures facing intense stress and challenges.M70 (Compressive Strength: 10,150 PSI): Applications: M70 Designed mix for projects requiring the highest compressive strength.Ideal for constructing structures where extreme strength is a critical factor. Concrete Grade Concrete Mix Ratio (Cement: Sand: Aggregates) Compressive Strength (MPa) Compressive Strength (PSI) M5 1:5:10 5 MPa 725 psi M7.5 1:4:8 7.5 MPa 1087 psi M10 1:3:6 10 MPa 1450 psi M15 1:2:4 15 MPa 2175 psi M20 1:1.5:3 20 MPa 2900 psi Standard Strength Concrete Grades M25 1:1:2 25 MPa 3625 psi M30 1:0.75:1.5 30 MPa 4350 psi M35 1:1.65:2.92 35 MPa 5075 psi M40 Design Mix 40 MPa 5800 psi M45 1 : 2.42 : 3.19 45 MPa 6525 psi Standard Strength Concrete GradesHigh Strength Concrete Grades M50 Design Mix 50 MPa 7250 psi M55 Design Mix 55 MPa 7975 psi M60 Design Mix 60 MPa 8700 psi M65 Design Mix 65 MPa 9425 psi M70 Design Mix 70 MPa 10150 psi Note: Design mix ratios for M30, M40, M45, M50, M55, M60, M65, M70 and other are project-specific and should be determined based on structural requirements. Always consult with a structural engineer for precise mix ratios please like share if you like our article on concrete mix ratio What is the design mix and compressive strength of Ordinary Grade Concrete (M10, M15, M20)? M10 Design Mix: Design Mix Ratio: 1:3:6 (Cement: Sand: Aggregates) Compressive Strength: 1,450 PSI M15 Design Mix: Design Mix Ratio: 1:2:4 (Cement: Sand: Aggregates) Compressive Strength: 2,175 PSI M20 Design Mix: Design Mix Ratio: 1:1.5:3 (Cement: Sand: Aggregates) Compressive Strength: 2,900 PSI What are the design mix ratios and compressive strengths of

What are load bearing walls : Load-bearing brick walls are walls constructed using bricks that serve a structural purpose by supporting the vertical loads of a building. These walls are an integral part of the building’s structure and play a key role in distributing the weight of the structure to the foundation. Load-bearing brick walls are designed to withstand compressive forces and provide stability to the overall construction. Karimnagar Bricks for Load Bearing walls Karimnagar bricks are suitable for use in load-bearing walls. These bricks are known for their structural integrity and durability, making them a reliable choice for various construction applications, including load-bearing walls. Here are some reasons why Karimnagar bricks are suitable for such purposes: Structural Integrity: Karimnagar bricks are designed to have excellent structural integrity. They can withstand the vertical load and pressure exerted by the structure above them, making them suitable for load-bearing applications. High Compressive Strength: Karimnagar bricks typically exhibit high compressive strength, which is crucial for load-bearing walls. This strength allows the bricks to support the weight of the structure without compromising stability. Uniform Size and Shape: Consistency in size and shape is essential for load-bearing walls to ensure even distribution of the load. Karimnagar bricks are often manufactured with precision, contributing to the uniformity required for load-bearing applications. Durability: The durability of Karimnagar bricks ensures that the load-bearing walls remain stable over time. These bricks are resistant to weathering and environmental factors, further enhancing their longevity in load-bearing structures. Natural Color Palette: The natural and earthy color palette of Karimnagar bricks adds an aesthetic appeal to load-bearing walls. Architects and builders often appreciate the visual charm these bricks bring to structural elements. Ease of Handling: Despite their strength, Karimnagar bricks are relatively lightweight, making them easier to handle and install. This characteristic can contribute to the efficiency of the construction process. It’s important to note that the suitability of any type of brick for load-bearing walls also depends on factors such as design specifications, local building codes, and structural engineering considerations. Therefore, it’s advisable to consult with a structural engineer or architect to ensure that the chosen bricks meet the specific requirements of the intended load-bearing application. is you like and share our article why Karimnagar bricks are used for loadbearing walls