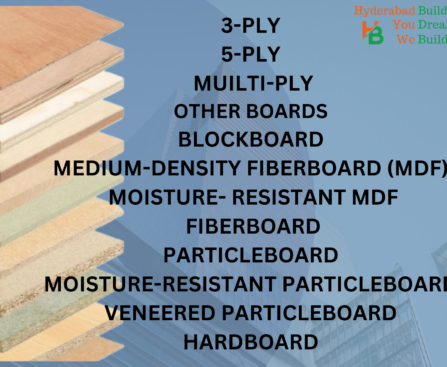

What and Why of Plywood Plywood is a multi-layered product made from thin wood veneers, compressed under heat and pressure with resin or chemical adhesives. This structure makes it stronger than natural wood. Plywood thickness varies from 4mm 5mm 6mm 7mm 8mm 12mm 16mm 18mm 24mm plywood impacting the number of veneer layers and, consequently, its strength. Quality Determinants of Plywood The quality of plywood is influenced by: The type and quality of wood used for veneers. Optimal log size, ideally 4ft x 2ft. The type of resin or adhesive used, with phenol-formaldehyde being superior. Types of Plywood for Interior Work Hardwood Plywood Softwood Plywood Gurjan Plywood Poplar Plywood Mixed Hardwood Plywood (Alternate Plywood) Sanded Plywood Structural Plywood Birch Plywood Beech Plywood Rubberwood Plywood Aircraft Plywood Blockboard-type Plywood Flexible Plywood Shuttering Plywood Rift-cut Plywood Quarter-sliced Plywood Plain-sliced Plywood Detailed types Plywood 1. Hardwood Plywood Primarily made from eucalyptus, known as Safeda in India. Celebrated for its rapid growth and high density. Utilized in specialized applications such as 710-Grade, Marine Grade, or Boiling Waterproof (BWP) products. Crucial to buy from reputable plywood brands to ensure durability. Ideal for environments that demand strong and resilient wood. 2. Softwood Plywood Comprised of lighter woods like pine and cedar. A bit pricier than other types and mainly used for structural purposes like building frameworks. Caution is advised against counterfeit products. Primarily applied in areas where structural integrity is crucial. 3. Gurjan Plywood Originates from Burma, Indonesia, Thailand, and Malaysia. A premium choice but increasingly rare due to logging restrictions. True Gurjan plywood is marked with the IS710-Grade tag. Known for exceptional strength and durability, making it sought-after for high-end construction and furniture. 4. Poplar Plywood Known for its low density, often referred to as cottonwood in India. Main varieties, G48 and W22, cultivated in Punjab and mountainous regions. Produced primarily in Yamuna Nagar, Haryana, typically carrying an MR grade. Lightweight and cost-effective, but limited in durability. 5. Mixed Hardwood Plywood (Alternate Plywood) Combines two timber species, often Eucalyptus and Poplar. Recognizable by alternating core color patterns. Available in grades like IS-303 or MR Grade. Versatile and cost-effective but with limited load-bearing capacity. 6. Sanded Plywood Known for its finely sanded surfaces, providing a smooth finish. Ideal for visible furniture parts like open cabinets and shelves. Comes ready for use, but with a specific application range. May not be as readily available due to its specialized nature. 7. Structural Plywood Designed for heavy-duty applications, capable of withstanding significant pressure and load. Commonly used in construction for framing, beams, and panels. High strength and load-bearing capacity. Generally not suitable for home or office interiors. 8. Birch Plywood Imported primarily from Russia and Finland, known for premium quality. Popular for its stunning finish, even thickness, and resistance to bending. Increasingly popular in India for high-quality furniture and interior applications. More expensive and may not be ideal for warmer climates. 9. Beech Plywood A mix of hardwood and European beech veneer. Inner core of Eucalyptus and a top layer of beech veneer. Provides a stunning wooden look after polishing, akin to veneers. Durable and cost-effective, ideal for a rustic wooden look on a budget. 10. Rubberwood Plywood Manufactured mainly in Kerala, one of the lowest-grade typ 11. Aircraft Plywood Initially used in WWII for British fighter aircraft, made from woods like Mahogany, spruce, and beech. Bonded with high-resistance adhesive, this plywood is high-strength and costly. Not typically available for regular market sale and more of a specialty item for specific requirements. 12. Blockboard-type Plywood Also known as plyboard, mainly used for vertical applications like wall paneling and shutters. Made with solid wood blocks or strips sandwiched between thick wood veneers. Suitable for areas where furniture shutters exceed 5 feet, but not for heavy load-bearing shelves or cabinets. 13. Flexible Plywood Known for its ability to bend into various shapes, used for design purposes like curves, arches, and round pillars. Flexible plywood offers unique design possibilities in furniture making. It should be sourced from well-known brands to ensure quality. 14. Shuttering Plywood Commonly used in the civil industry for constructing beams and roofs. With a hardwood core, this type of plywood is primarily used in construction sectors and not meant for interior or furniture-making purposes. 15. 3-ply Plywood Consists of three layers of veneer, thinner and less expensive than multi-ply options. Often used in decorative applications where weight and cost are considerations. Suitable for light-duty applications and temporary structures. 16. 5-ply Plywood Comprises five layers of veneer, offering a balance between strength and weight. More stable than 3-ply, it is suitable for a variety of interior applications, including furniture and paneling. 17. Multi-ply Plywood Made of multiple layers of veneer, providing excellent strength and stability. Ideal for heavy-duty use in both structural and decorative applications. Often used in areas requiring robust material, like flooring and heavy furniture. 18. Plain-sliced Plywood Features a “cathedral” or “flame” grain pattern, resulting from slicing the log parallel to its length. Common and cost-effective, suitable for cabinetry, furniture, and interior paneling, where a traditional wood appearance is desired. 19. Rift-cut Plywood Produced by slicing the veneer at a slight angle to the radial plane. Features a straight, consistent grain pattern, less prominent than plain-sliced. Often chosen for modern furniture and cabinetry where a uniform look is desired. 20. Quarter-sliced Plywood Created by slicing veneer at a right angle to the growth rings, producing a fine, regular grain pattern. Known for its elegant and upscale appearance. Used in high-end furniture and architectural applications where a refined look is essential. so far we have covered various types of plywood used in Home interiors Building Materials Now let lets look into what are various grades of plywood Some of the plywood facts Plywood Grades Understanding the different grades of plywood is crucial for selecting the right type for your needs, as they indicate quality and durability. 1. Marine Grade Plywood or IS-710 Grade Plywood Highest grade available in India, ideal for interior work and furniture making.

Introduction: Congratulations on finding your potential new home or investment property! While it’s an exciting milestone, it’s also the time to be meticulous and cautious. To verify documents its a critical step in the property-buying process. It’s not just about checking the legitimacy of the property, but also about ensuring that your investment is protected from legal disputes and future complications. How to Verify Documents Title deed : Start by verifying the title deed of the property with the assistance of a legal expert. Ensure that the seller has the legal right to sell the property, and there are no disputes or encumbrances on the title. Obtain a copy of the title deed from the seller and cross-check it with the land records available at the local sub-registrar’s office, consulting a property specialist if necessary. Encumbrance Certificate: Request an encumbrance certificate for the property from the sub-registrar’s office, and have it examined by a legal expert. This document shows all transactions related to the property, including mortgages, leases, and transfers. Ensure there are no outstanding dues or legal issues mentioned in the encumbrance certificate with the assistance of a property specialist. Verify Land Use: Confirm that the property’s land use aligns with your intended use, consulting a property specialist for guidance. Different zones have specific land use regulations, and any deviation can lead to legal issues in the future. Consult with the local municipal authority to understand the land use classification of the property, with the help of a legal expert if required. Property Tax Receipts: Request copies of property tax receipts for the past few years from the seller, and review them with the assistance of a property specialist. This will confirm that there are no pending property tax payments. Verify the property’s assessment value and the tax amount paid to avoid any discrepancies, consulting a legal expert if needed. Approved Building Plan: If the property includes a constructed building, ensure that the building plan is approved by the local municipal authority, and have it reviewed by a legal expert. Check for deviations from the approved plan, as unauthorized constructions can lead to legal troubles, with the guidance of a property specialist. No Objection Certificates (NOCs): Obtain NOCs from relevant authorities for properties located near airports, defense areas, heritage sites, or coastal zones, and have them scrutinized by a legal expert. Verify that there are no restrictions on construction or development in the area, with the help of a property specialist if necessary. Sale Agreement and Sale Deed: Carefully review the sale agreement and sale deed with the assistance of a legal expert and a property specialist. These legal documents should contain all the terms and conditions of the sale. Ensure that the details in these documents match the property’s actual status and the agreement between you and the seller, seeking expert advice when necessary. Due Diligence through Legal Experts and Property Specialists: Consider hiring both a legal expert and a property specialist to perform a thorough due diligence check on the property. Legal professionals can identify any potential legal issues, while property specialists can provide insights into the property’s market value and potential for growth. Related articles: How to register property at rera telangana, What 7/12 extract document? Conclusion: Verifying property documents is a crucial step in the property-buying process in India, and seeking the guidance of legal experts and property specialists can provide you with a comprehensive understanding of the property’s legal and market aspects. This approach helps you avoid legal disputes, fraudulent transactions, and financial losses, ensuring a smooth and informed property purchase experience in India. Remember, it’s always better to be cautious and well-informed before making such a significant investment. Disclaimer: This guide offers general property document verification advice for Indian buyers. Seek professional advice, conduct thorough research, and make informed decisions tailored to your unique circumstances when purchasing property in India.

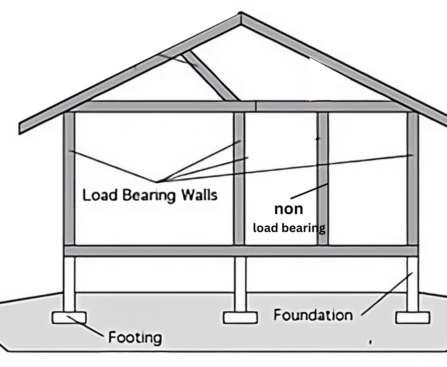

What is Load-Bearing wall? Definition: A load-bearing wall is any structural element supporting other elements or structures above it, such as the roof, floors and walls. It plays an important role in carrying the load from roof and upper stories to footings below.Characteristics: The walls are often built of durable materials like brick, stone or concrete. They are usually thicker than non-load-bearing walls and form an important component of the structure. Load bearing wall thickness: 230-250mm (9-10 inches) its the standard thickness. What is Non-Load-Bearing wall? Definition: The major function of non-load-bearing walls (or partition walls), is to divide up the different spaces within a building. They do not support any structural load of the building, other than their own weight and perhaps some additional superficial loads like covering.Characteristics: Walls here are also lighter and thinner than load-bearing walls, often construction materials like gypsum boards, timber or metal frames. They can also be easily adjusted or changed without affecting the building’s stability. Non-load bearing wall thickness: the standard thickness 100-115mm (4-4.5 inches). these thickness changes as per the requirement What is the distinction between Load-bearing and Non-load Bearing Walls? Structural Role: Walls that bear load are necessary to ensure the stability of a building, while non-load bearing walls only separate space and provide privacy.Material and Construction: These are built with stronger materials and thicker to accommodate increased loads. On the other hand, non-load bearing walls are constructed with lighter materials and not designed to carry heavy loads.Flexibility in Alteration: Walls that are not load bearing can be modified or done away with without compromising the stability of the building. But since changing a structural element weakens this basic stabilizing function, doing so to an actually requisite-load carrying wall must involve some thought and normally requires additional concrete work (ACW) Types of Load-Bearing Walls Exterior Walls: In the past, most load-bearing walls were on outside of building.Interior Walls: Interior walls can also be load-bearing in some designs, including larger or multi-story works. Non-Load Bearing Walls–Types Partition Walls: Once used to divide the spaces between various rooms in a building.Decorative Exterior Walls: If the building has an interior framework or other means of support, then some exterior walls may be non-load bearing Related articles: Types of brick wall, Brick wall cost calculator, How to check brick quality, Precast walls, pre cast boundary walls

What is Brick wall A brick wall is a structural element commonly used in construction, consisting of bricks laid in a specific pattern and bonded together with mortar. Bricks, typically made from fired or sun-dried clay, are small, rectangular blocks. Brick walls are known for their durability, strength, and aesthetic appeal, and they can be used both as load-bearing walls and as decorative or partition walls in various types of buildings. Before knowing types of brick wall it is essential to know what is load beading what is non loading bearing walls to better understand what kind of brick wall is needed for you construction needs. Load bearing Walls: A load-bearing wall is a structural element that supports the weight of components above it, such as the roof, floors, or other walls. It plays a crucial role in transferring the load from the roof and upper floors down to the foundation. Non-Load bearing Walls: Non-load-bearing walls, also known as partition walls, are used primarily for dividing spaces within a building. They do not support any structural weight of the building except their own weight and possibly some minimal additional loads like cladding. to know more on load bearing non loading bearing walls we cover another article Types of Brick walls There are several types of brick walls, each differing in construction, design, and purpose. Here’s an overview of the most common types:Solid Brick WallsCavity Brick WallsBrick Veneer WallsHollow Brick WallsReinforced Brick WallsFire Brick Walls Solid Brick Wall Construction: Made of solid bricks laid closely together with mortar. No gaps or cavities.Purpose: Historically for load-bearing walls due to strength and durability.Characteristics: Sturdy and robust, poor insulation, susceptible to moisture. Cavity Brick Wall Construction: Two layers of bricks with a cavity between them. Purpose: Better insulation and moisture prevention. Characteristics: Improved thermal and sound insulation. Cavity can be filled with insulation material. Veneer Brick Wall Construction: Single layer of bricks attached to a structural frame or another material.Purpose: Mainly aesthetic; not load-bearing.Characteristics: Thinner layer, primarily decorative, some insulation. Hollow Brick Wall Construction: Made using hollow bricks with internal holes or cavities.Purpose: Lighter and better insulated than solid brick walls.Characteristics: Reduces weight of the structure, improves thermal performance. Reinforced Brick Wall Construction: Bricks with steel reinforcement in a grid pattern.Purpose: Additional strength, especially in seismic areas.Characteristics: Higher stability and stress resistance. Fire Wall Construction: Built with fire-resistant materials, often thicker.Purpose: Prevents or slows fire spread between building sections.Characteristics: Meets specific fire resistance ratings, acts as a barrier. Frequently asked questionsWhat Type of Wall is Brick? The three most common types of brick walls are solid, cavity, or veneer brick walls. Each type has distinct attributes and benefits. Which Brick Wall is Stronger? Traditional red bricks are considered more robust and stronger than hollow block structures. They are suitable for load-bearing walls. Which Brick is Long Lasting? Red bricks are known for their strength and durability. They have a higher compressive strength compared to fly ash bricks, making them suitable for load-bearing applications and capable of withstanding heavier loads.

Bricks price in Hyderabad Skyrocketing Raw Material Shortage and Transportation Woes Fuel the Crisis As brick costs continue to rise to unprecedented levels, Hyderabad’s construction sector is presently facing a significant challenge. A serious lack of construction raw materials and transportation issues are primarily responsible for the surge in brick prices that has sent shockwaves through the real estate industry. Bricks Price in Hyderabad Over the past six months, brick prices in Hyderabad have increased alarmingly, rising by as much as 40% compared to previous levels. The core of the issue lies in the shortage and increased costs of vital raw materials used in brick manufacturing, namely clay, sand, and coal. Manufacturers are finding it increasingly difficult to procure these essential resources, resulting in disruptions in the production process. Transportation Issues and Material Shortages Escalate the Problem In addition to raw material scarcity after covid transportation challenges have exacerbated the crisis. Rising fuel prices have driven up transportation costs, burdening brick manufacturers with higher shipping expenses. Consequently, suppliers have no choice but to pass on these increased costs to buyers, further driving up brick prices. its almost 75 to 100% hike in Brick prices after covid Current brick prices in Hyderabad: Grade C from ₹5- ₹7.5 Grade B from ₹ 7.5 – ₹10 Grade A ₹ 9 – ₹15 Price Hike Leaves Consumers in Despair Local builders, developers, and homeowners in Hyderabad are all feeling the impact of the price increase. Builders in Hyderabad are struggling to cope with the unexpected financial burden caused by halted construction projects and declining profit margins. With construction costs on the rise, Hyderabad’s real estate sector, which had been growing steadily, is now experiencing instability. Exploring Sustainable Construction Methods As the situation continues to evolve, industry experts recommend that construction companies in Hyderabad explore innovative and sustainable construction methods that require fewer bricks. Additionally, fostering long-term agreements with brick suppliers can help mitigate the impact of price fluctuations. In Conclusion The soaring brick prices in Hyderabad have become a pressing concern for the construction industry in the city. Identifying sustainable solutions and promoting cooperation among stakeholders is crucial to ensure the sector’s continued growth and stability. According to experts, it may be wise to invest in bricks now, as prices could rise even further to unprecedented levels. Related articles: How to check brick quality , History of Bricks Hyderabad Builders, a construction material supplier in Hyderabad, offers the best deals on the purchase of construction materials in the city. For inquiries and assistance, please feel free to contact us at Hyderabad Builders, and we will be happy to assist you in addressing your construction material needs. Brick Calculator Total Square Feet: Wall Thickness: 9-inch 4-inch Calculate Total Bricks Required: 0 All Posts Blog Construction Cost In Hyderabad Per sft How to Minimise January 7, 2024/No Comments “The construction cost in Hyderabad ₹1450 to ₹2200 sft varies significantly from one location to another, quality to quality and… Read More Construction cost for G+2 January 7, 2024/No Comments What is G+2 building? A G+2 building refers to a structure that consists of a ground floor plus two additional… Read More 2024 Construction Technologies January 5, 2024/No Comments Introduction: Embracing the Future of Construction Technology In the ever-evolving landscape of the construction industry, 2024 marks a pivotal year… Read More 2024 construction labor Cost Rates per Sft per day January 4, 2024/2 Comments Construction labor rates in India Introduction: In the ever-evolving landscape of India’s construction industry, the adept management of labor costs… Read More Tata Pravesh Doors Prices January 1, 2024/2 Comments Once the construction phase of a building is completed, the focus turns to the… Read More Building Materials 2024 December 30, 2023/1 Comment 2024 Construction Building Materials Price List When planning any building construction project, whether it’s a small home renovation or a… Read More Century Plywood Company December 30, 2023/No Comments Planning Your Home Interior with Century Plywood When it comes to planning your home interior and considering furniture making, Century… Read More About Greenply plywood prices sixes grades December 30, 2023/No Comments Greenply Industries Ltd Plywood Products and Prices Greenply Industries Ltd. is a renowned name in the Indian wood-based home interiors… Read More Top Plywood Brands December 30, 2023/1 Comment Introduction: New year new dream news aspirations Are you planning for home interiors in 2024 and on a quest to… Read More Load More End of Content.